882.00207.00 Chapter 4: Operation 55 of 102

Weigh Hopper Dump Cycle

The dump cycle allows the weigh hopper dump valve to cycle or open and close a number of times

prior to commencing with the next batch cycle. The setting allows from 1 to 9 dump cycles between

batches (open and closed cycles).

The normal and default factory setting is 1, meaning the weigh hopper dump valve will open at the

end of the weighed batch and close after the batch is discharged into the mixer.

Setting the dump cycle to more than one cycle may be useful when blending high static, dusty

material or those that have sticky tendencies. This will cycle the dump valve open and closed to

allow any material that may cling to the dump valve.

To enter the dump cycle menu, first enter the Setup menu by pressing the Manufacturer’s icon from

the main menu. Enter the password and press enter. Next, press the button marked “Mixer and Dump

Setup.” The display will show the “Mixer and Dump Setup” menu. Press the “Dump Cycle” key to

enter a dump cycle value and press enter. Please refer to the menu structure tree shown in section 3-

5.

Mixer Dump Time

The mixer dump time is the amount of time the knife gate below mixer’s valve remains open to

allow blended material to exit the blender.

To view and change the current mixer dump time settings, enter the Setup menu and select the

“Mixer and Dump Setup” screen. Press the field next to “Mixer Dump Time” to set the operation of

the Dump Valve.

The dump timer on the dump valve has a default time of six (6) seconds. This time can be adjusted

to optimize the blender cycle time.

The timer should be set to close the dump valve shortly after clearing the high-level sensor. This

time can vary due to material flow characteristics and the size of the batch that is programmed into

the blender control. Experimentation with this setting can allow the operator to determine the best

cycle for the material being mixed.

Alarm Flags

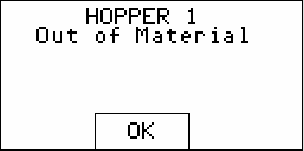

An alarm message will be shown if any alarm condition occurs. A message will pop up on the

screen until the alarm condition is resolved. The operator can press “OK” on this pop-up to hide the

screen temporarily, but if the alarm condition is still unresolved, then the message will reappear after

a short delay. During an alarm condition, not only will a visual alarm show up on the screen but also

an audible alarm will sound. The audible alarm will sound for 10 seconds and reappear every 30

seconds until the cause of the alarm is resolved. The following is a list of all alarm names and

descriptions:

Hopper 1-6 Out of Material

This alarm indicates that a hopper is out of material and signals the operator that they should check

the resin system.

Typical “Out of Material” Alarm Screen