882.00207.00 Chapter 6: Troubleshooting 66 of 102

Chapter 6: Troubleshooting

6-1 Introduction

The utmost in safety precautions should be observed at all times when working on or around the

machine and the electrical components. All normal troubleshooting must be accomplished with the

power off, line fuses removed, and with the machine tagged as out of service.

The use of good quality test equipment cannot be overemphasized when troubleshooting is indicated.

Use a good ammeter that can measure at least twice the AC and DC current that can be encountered

for the machine. Be sure that the voltmeter has at least minimum impedance of 5,000 OHMS-per-

volt on AC and 20,000 OHMS-per-volt on DC scales. Popular combination meters, VOM and

VTVM can be selected to provide the necessary functions.

Before making haphazard substitutions and repairs when defective electrical components are

malfunctioning, we recommend that you check the associated circuitry and assemblies for other

defective devices. It is common to replace the obviously damaged component without actually

locating the real cause of the trouble. Such hasty substitutions will only destroy the new component.

Refer to wiring diagrams and schematics.

Locating mechanical problems, should they occur, is relatively straightforward. When necessary,

refer to the parts catalog section.

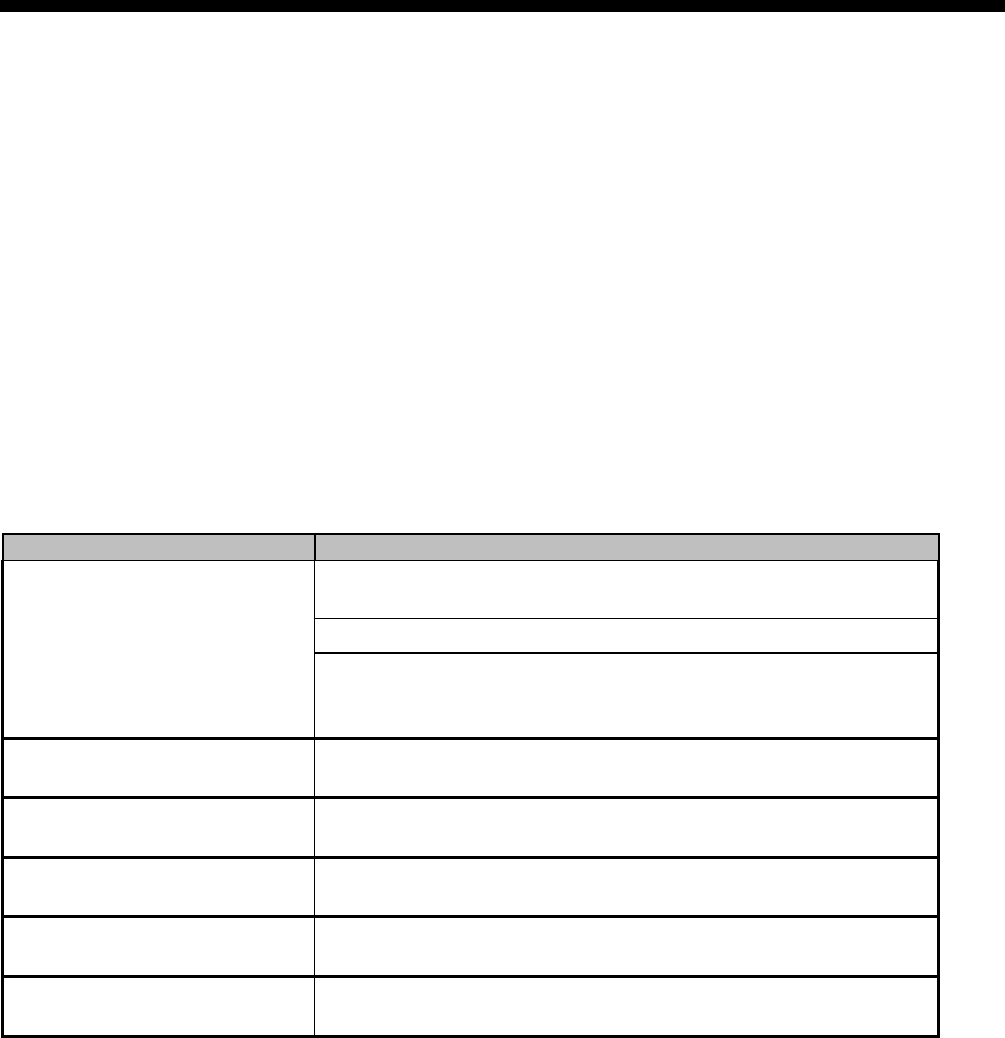

Figure 45: Typical Troubleshooting Problems and Suggested Corrective Actions

Problem Corrective action

Check to make sure that air is hooked up and the regulator gauge

reads at precisely 60 PSI.

Check that the access door to the mixer is shut properly.

Nothing happens when I push

“Start Blender”

Look on the Recipe Screen. If you see “Mixer Full”, then check

the mixer. If the mixer is not full, then check that the mixer prox

is adjusted properly (small screw on back).

“E-STOP has been Activated”

is shown

Check the E-Stop located on the front of the blender panel.

“Interface has been Locked” is

shown

Click “Unlock” and enter in your User Password.

I’ve forgotten my User

Password

Contact the Service Department.

POWER INTERRUPTION

ALARM

Power was lost during a batch. Check your power source unless

you intentionally interrupted the power during the batch.

PLC Battery Low

Change out the PLC with your spare and reprogram new unit.

Send old PLC back to manufacturer for repair.