30 04581740_ed2

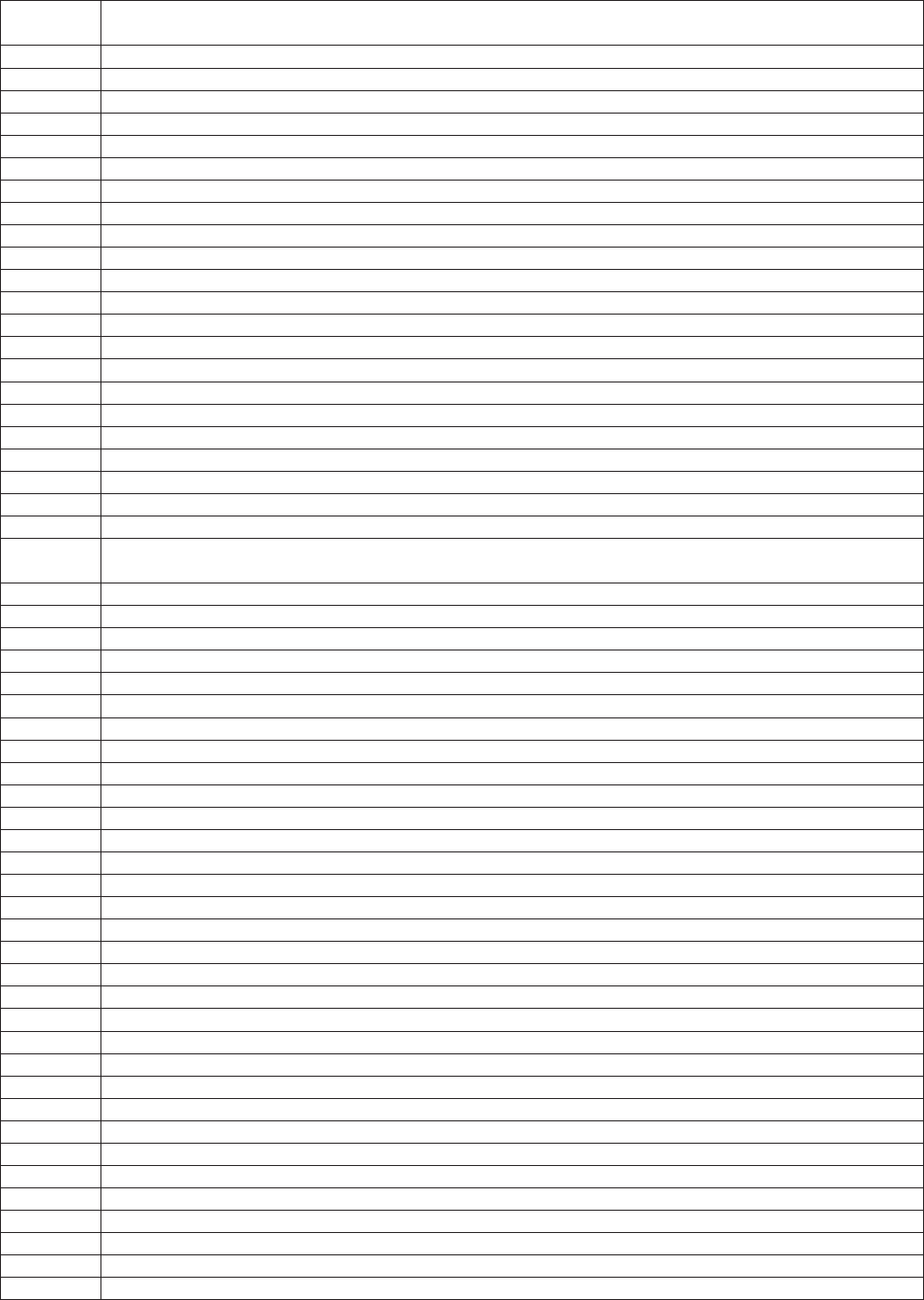

The SD Code column on the Cycle Log shows the Shutdown Code for each cycle. The shutdown code is a 2-digit code

that gives the reason why the cycle stopped. See a list of the shutdown codes in the table below.

Shutdown

Code #

Description

0 Normal Completion of Cycle

1 Handheld – Trigger released before cycle was complete

2 Torque High

3 Angle High

4 Yield override failure

5 Prevailing torque seating torque fail

6 Prevailing torque seating angle fail

7 Reserved for future use

8 Forced to shutdown because sync ag was set

9 Reserved for future use

10 Motor stalled (I2t limit reached)

11 User tr is less than the target torque which would cause a stall

12 MCE – IGBT fault

13 MCE – Overcurrent

14 MCE – Low bus voltage

15 Cycle timeout

16 The controller issued a stop command to the tool.

17 The tool was disconnected during cycle

18 MCE – communications lost between MCE and the controller

19 Bad Torque Reference - torque step ref+tare-overshoot is > the step limit

20 MCE – Watchdog timer red

21 Retorque steps complete without reaching the setpoint

22

When “yield override” is enabled and “fail on yield” is disabled, if the nal torque reached is below the

torque low limit

23 Cycle stopped due to tool becoming disabled

24 Stick slip occurrence

25 Slope A/Gradient high

26 Reserved for future use

27 Slope B high

28 No bolt was found

29 Proximity Switch – normal shutdown

30 MCE – motor temperature high

31 MCE – drive temperature high

32 Spindle TactAlert – normal shutdown

33 Cycle ended before achieving threshold torque

100 Powerhead – spindle stopped due to command from powerhead master

101 Powerhead – spindle in bypass

102 Powerhead – undetermined prerun error

103 Powerhead – spindle emergency stop activated while in cycle

104 Powerhead – Trigger Abort – trigger inputs removed before spindle achieved torque threshold

105 Powerhead – Prerun error – no tool connected

106 Powerhead - Prerun error – invalid tool connnected

107 Powerhead - Prerun error – invalid conguration to run

108 Powerhead – Prerun error – settings error – conguration step counts do not match

109 Powerhead – Prerun error – settings error – synchronization maps do not match

110 Powerhead – Prerun error – settings error – Job IDs do not match

111 Powerhead – Prerun error – spindle emergency stop activated

112 Powerhead – Prerun error – spindle in diagnostics mode

113 Powerhead – Prerun error – spindle not ready to run

114 Powerhead – Prerun error – spindle disabled (master only)

115 Powerhead – Prerun error – cannot lock cong to run

116 Powerhead – Prerun error – settings CRC does not match

117 Powerhead – Prerun error – unexpected CRC message

118 Powerhead – MCE calibration failed

119 Powerhead – MCE motor over temperature fault

120 Powerhead – MCE motor heatsink over temperature fault