38 04581740_ed2

Appendix 1 – System Specs and Spare Parts

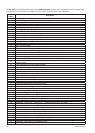

Insight Technical Specications

The specications for the Insight IC Tightening System are shown below.

Measurement Accuracy

±0.2% of torque full scale

±1 count of angle (degrees)

Measurement Resolution ±0.025% of torque full scale

Torque Transducer Bridge Excitation ±5VDC/GND

Torque Transducer Zero Oset/Drift

Compensation

±0.4% of full scale

Input Signal Sensitivity 2.0 mV/V

Calibration

Values read from spindle memory

Automatic digital correction

Frequency Response (Torque Filter) Selectable 75 Hz, 150 Hz, 350 Hz, 500 Hz, 750 Hz

Keypad (IC-D only)

Membrane keypad containing four hot keys, four function keys, numerical

keypad and directional keypad.

Display

IC-D-3.5-inch diagonal, 320px by 240px, 8-bit 65K backlit color (QVGA) at panel

display.IC-M--5-character, 7-segment numerical LED display.

Parameter Sets 256

Number of Cycles Stored in Memory IC-D: 1,000. IC-M: 200.

Statistics Data Memory 100,000 per spindle

Communications Serial RS232, Ethernet, USB, Optional Probus or DeviceNet.

I/O

8 inputs/8 outputs, with behavior assignable through ICS Software. With

optional I/O card, an additional 16 inputs and outputs are available.

Indicators Power ON lamp

Optional Devices DeviceNet Card, Probus Card, Additional I/O, Cabinet Mounting Bracket.

Input Voltage Single Phase 120 Volts, 50/60 Hz, 16 Amps

Single Phase 230 Volts, 50/60 Hz, 8 Amps

Ambient Operating Conditions 0-50° C, 20/90% non-condensing humidity

Enclosure IP-52

System Weight 12.4 pounds (5.6 kg)

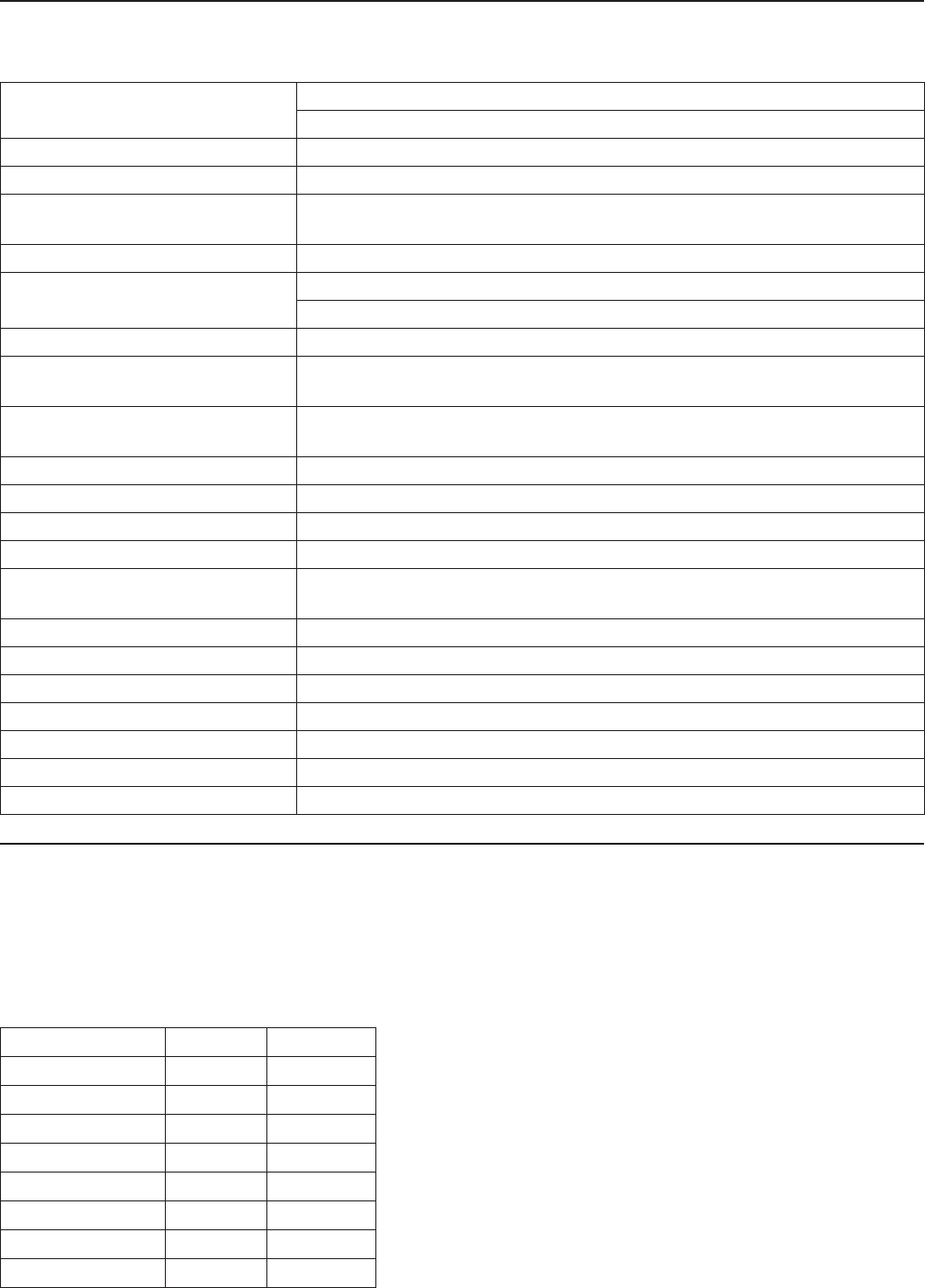

Pinout Tables

Default I/O Assignments

Below are the default Pinout assignments for the base I/O of the IC-D and IC-M controllers

NOTE: I/O Behaviors are assignable through ICS Software.

Inputs

Intput Behavior Block # Pin #

Freespeed 1 I-1

Softstart 1 I-2

Forward 1 I-3

Reverse 1 I-4

Conguration 1 1 I-5

Conguration 2 1 I-6

Conguration 3 1 I-7

Conguration 4 1 I-8