A-9

INSTALLATION

MAXsa™ 22 & 29 WIRE DRIVES

A-9

ELECTRODE CONNECTIONS

Because the Power Wave® AC/DC 1000 SD can pro-

duce either a DC positive, DC negative or AC output the

electrode and work connections do not need to be

reversed for the different polarities. Additionally no DIP

switch changes are required to switch between the dif-

ferent polarities. All of this is controlled internally by the

Power Wave® AC/DC. The following directions apply to

all polarities:

Connect the electrode cable(s) to the "ELECTRODE"

stud(s) on the power source . Connect the other to the

contact assembly at the Wire Drive. Be sure the con-

nection makes tight metal-to-metal electrical contact.

The electrode cable should be sized according to the

specifications given in Table A.1.

NOTE: On the Power Wave® 1000 SD, the Electrode

studs are on the lower left rear corner of the

machine. On older units they are on the lower

left front corner. On those machines,

the

cables can be routed through the oval hole in

the cable tray before being connected to the

output terminals.

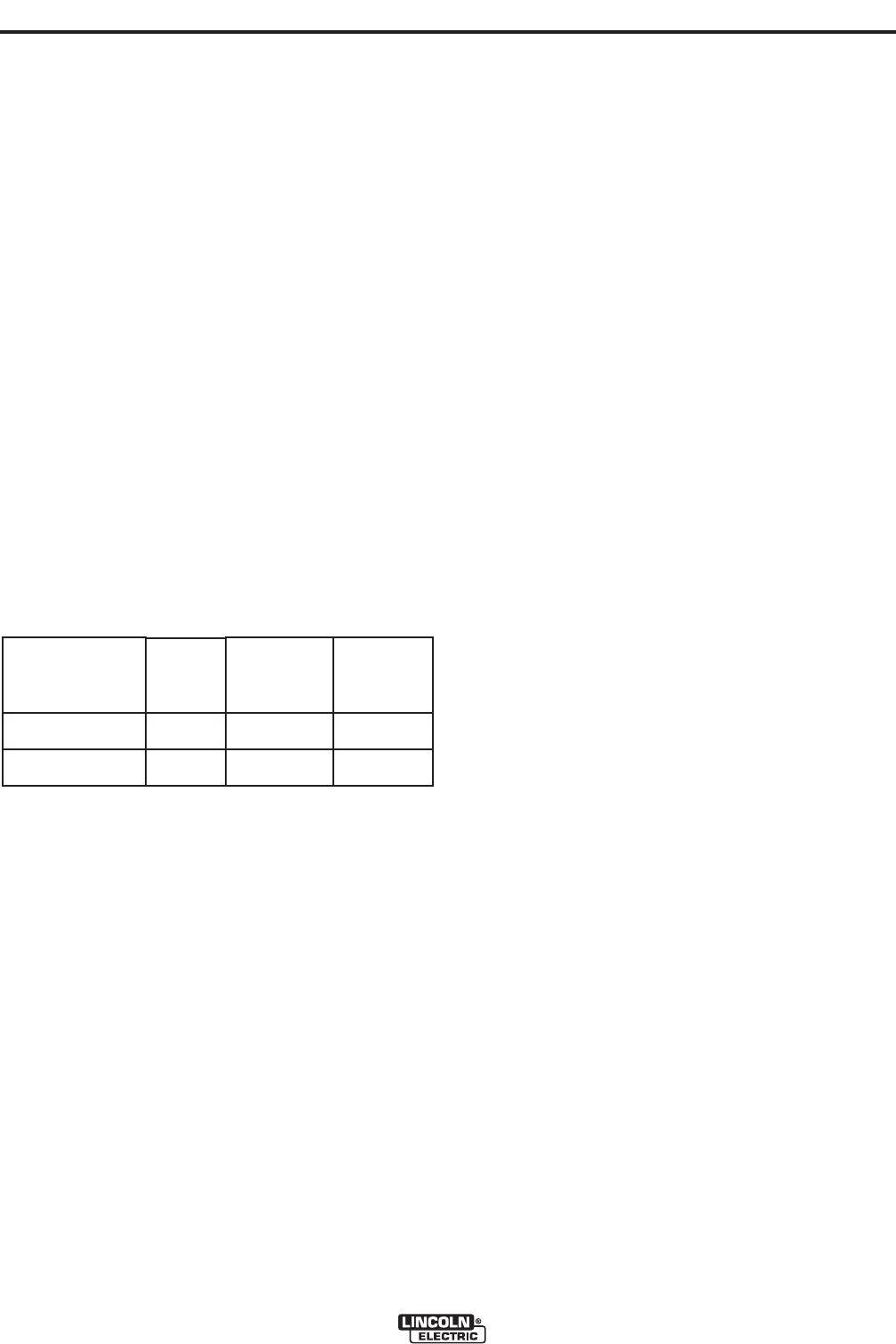

TABLE A.1 - Output Cable Guidelines

When using inverter type power sources like the

Power Wave®, use the largest welding (electrode and

work) cables that are practical. When using AC appli-

cations the current can reach very high levels. Voltage

drops due to cable resistance can become excessive,

leading to poor welding characteristics if undersized

welding cables are used.

REMOTE SENSE LEAD SPECIFICATIONS

The MAXsa™ 22 & 29 Wire Drives has an ELEC-

TRODE sense lead extending from the connection

box that is mounted to the motor. This sense lead is

critical to the accuracy of the Power Wave® welding

process. A ring terminal is provided at the end of the

lead. This lead must be extended and connected to

the electrode connection at the nozzle. This connec-

tion should be made as close to the welding arc as

possible. Use at least a 12 AWG wire with a proper

sized ring terminal. Use a screw with a lock washer

and nut to make the connection, then insulate the con-

nection with electrical tape. Proper care should be

taken to protect the sense lead from becoming discon-

nected or damaged. The loss of a sense lead connec-

tion can adversely affect welding performance. The

system may have multiple sense lead configurations

available. Consult the power source manual on how to

configure the power source for the sense leads.

NOTE: The WORK sense lead (21) for the MAXsa™

22 & 29 Wire Drives system is typically con-

nected at the back of the Power Wave®

AC/DC 1000 SD. If the MAXsa™ wire drive is

to be used in an older system, (PF10A and/or

K2344-X) the WORK sense lead must be

brought out of the motor connection box and

connected to the workpiece.

Total Cable Length

ft (m)

Electrode and Work

Combined

0 (0) to 250 (76.2)

0 (0) to 250 (76.2)

Duty Cycle

80%

100%

Number of

Parallel Cables

2

3

Cable Size

Copper

4/0 (120 mm

2

)

3/0 (95 mm

2

)