C-7

ACCESSORIES

MAXsa™ 22 & 29 WIRE DRIVES

C-7

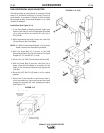

K285 Installation with K149

1. Install the K149 to the K148 per the instructions.

2. Loosen the hose clamps of the K285 entirely, place

them around the nozzle and tighten them so that

the stationary part of the K285 is directly opposite

the K149 arm. See Figure C.10

NOTE: The lower hose clamp must be positioned so it

does not touch the arm of the K149.

4. Position the moveable section to the desired flux

height and tighten the wing nut. Use the center or

lower tapped hole depending on the electrical

stickout

5. Cut the flux hose to required length and connect as

shown.

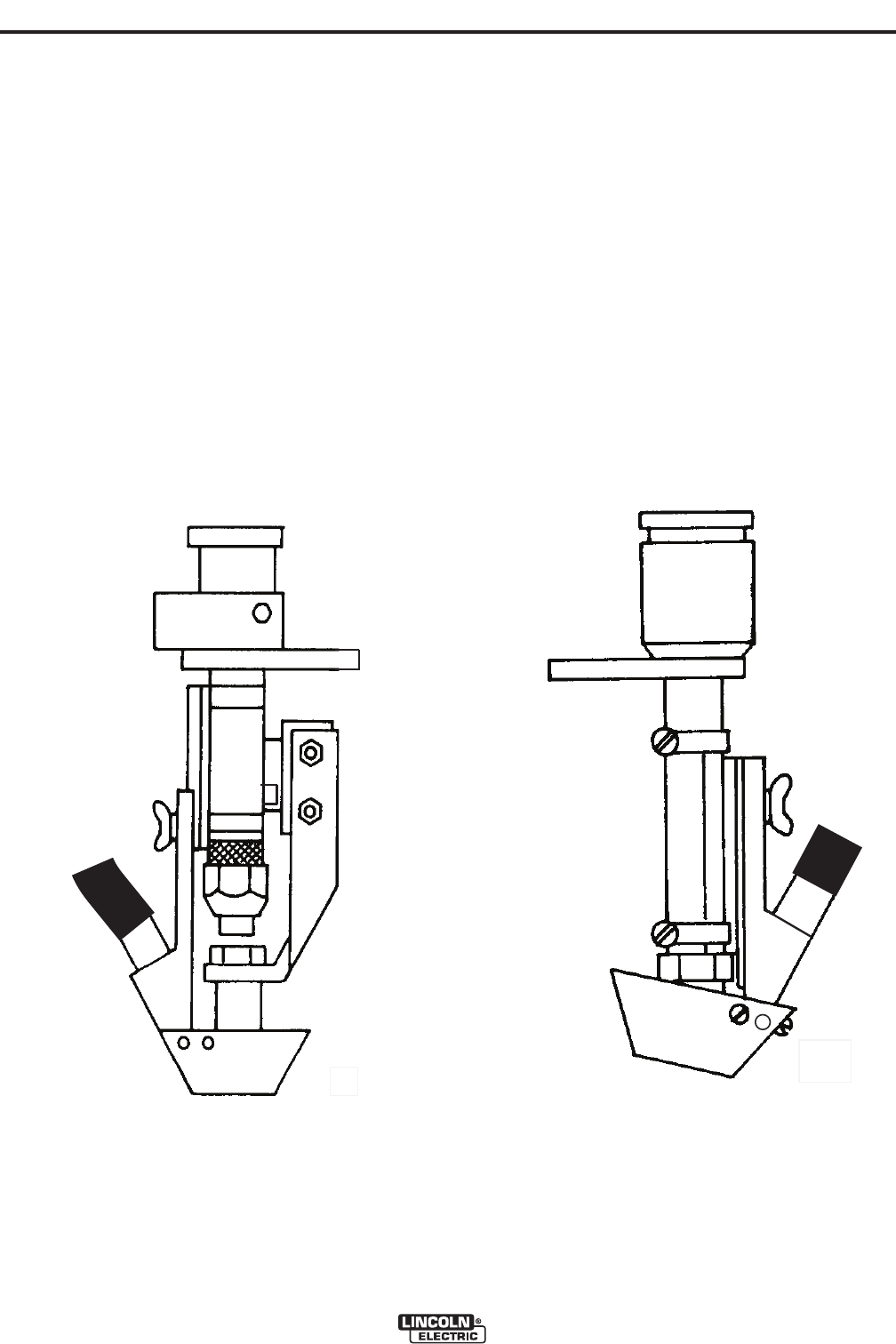

K285 installation with the K129

1. Unscrew the hose clamps enough so they can slip

over the tip holder clamping nut.

2. Position the stationary portion of the K285 as

shown in Figure C.11 and tighten the clamps.

3. Position the moveable section to the desired flux

height and tighten the wing nut.

4. Due to the 7° angle of the tips it may be necessary

to pivot the cone as shown. Remove the outermost

screws from each side of the cone. tilt the cone

and put the two screws into the rear of the cone.

Tighten all 4 screws.

5. Cut the flux hose to required length and connect as

shown.

IMPORTANT

K285 on ALL Nozzles

After the K285 is installed to any of the compatible

nozzles, use an ohmmeter or a test light to insure

proper insulation (no continuity) between the copper

flux cone and the nozzle body

FIGURE C.10 - K285/K149

FIGURE C.11 - K285/K129