B-2

OPERATION

B-2

MAXSA™ 22 & 29 WIRE DRIVES

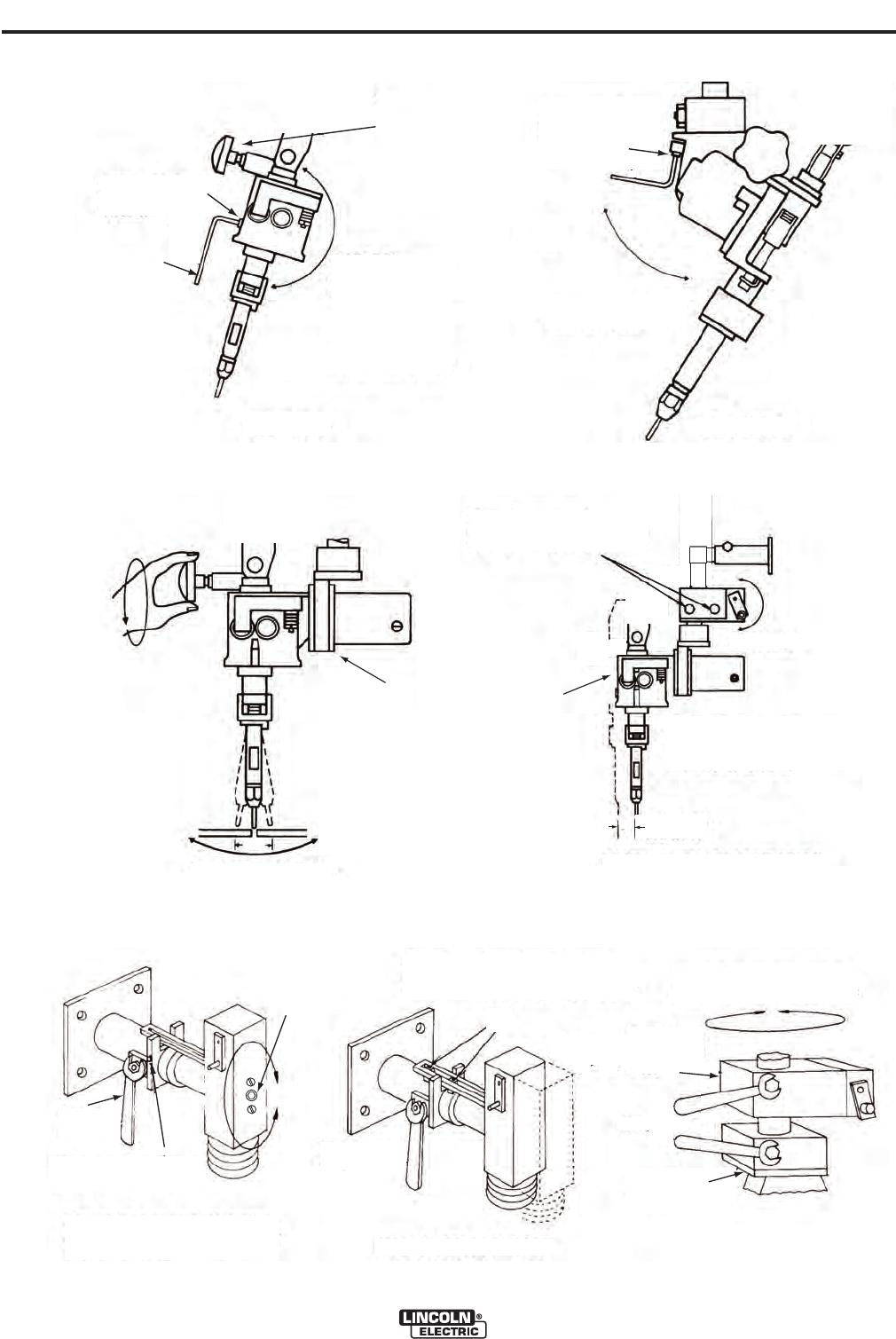

FIGURE B.2 - HORIZONTAL ADJUSTMENT

This Adjustment Can be

Locked by Tightening

Two Socket Head Screws

Rotating the K96 Allows

for 2” Movement in

any Direction in the

Horizontal Plane

Turn Handle

to adjust

Cross Seam Adjuster

K96 Horizontal Adjuster

MAXsa 29

MAXsa 22

2 1/2”

2

”

FIGURE B.1 - FEED HEAD ADJUSTMENT

Loosen this Socket

Head Screw to Adjust

Faceplate Angle

5/16”

Allen

Wrench

Face-plate Rotates

360° Around the

Drive Roll Shaft

Feed Head Rotates

360° Around the

Motor Axis

T

he Cross Seam Adjuster

Can Be Mounted to the

Top or Bottom of the

Gear Box

FIGURE B.3 - VERTICAL ADJUSTMENT

With Standard Mounting (M6767)

or K29 Vertical Adjuster

Loosen to Rotate

Entire Head Around

Mounting Axis

With K29

Loosen Screw

K29 Clamps Can Be Set

to Restrict In and Out Motion

to Distances up to 3 3/4”

Head May Be Rotated

Around the Vertical Axis

K96

Head

Mounting

With Standard Mounting (M6767)

or K96 Horizontal Adjuster

Use This Screw

To Lock Vertical

Position