C-4

ACCESSORIES

C-4

K148 CONTACT NOZZLE AND K149 Linc-Fill

TM

LONG STICKOUT EXTENSION

This nozzle is available in three models and can be

used for Innershield® or submerged arc processes.

K148-A - For 3/32” and 1/8” (2.4 - 3.2mm) wire.

K148-B - For 5/32” and3/16” (4.0 - 4.8mm) wire.

K148-C - For 1/16” to 5/64” (1.6 to 2.0mm) wire.

Current Ratings

A. Without Linc-Fill Attachment

Innershield Welding:

600 amps, 100% duty, no water cooling

1100 amps, 100% duty, with water cooling

Submerged arc welding:

1100 amps, 100% duty, no water cooling

B. With K149 Line-Fill Attachment

Innershield or Submerged Arc Welding:

1100 amps, 100% duty, no water cooling

Water Cooling Attachment

When using currents over 600 amperes at high duty

cycles water cooling always increases contact tip life.

The cooling attachment, Part No. T12928 must be

ordered seperately. Installation instructions are includ-

ed in the kit. Connect the attachment to the water sup-

ply and the drain with rubber tubing obtained locally.

Water flow should be between 1/2 to 1 gallon (1.9 to

3.8L) of tap water per minute.

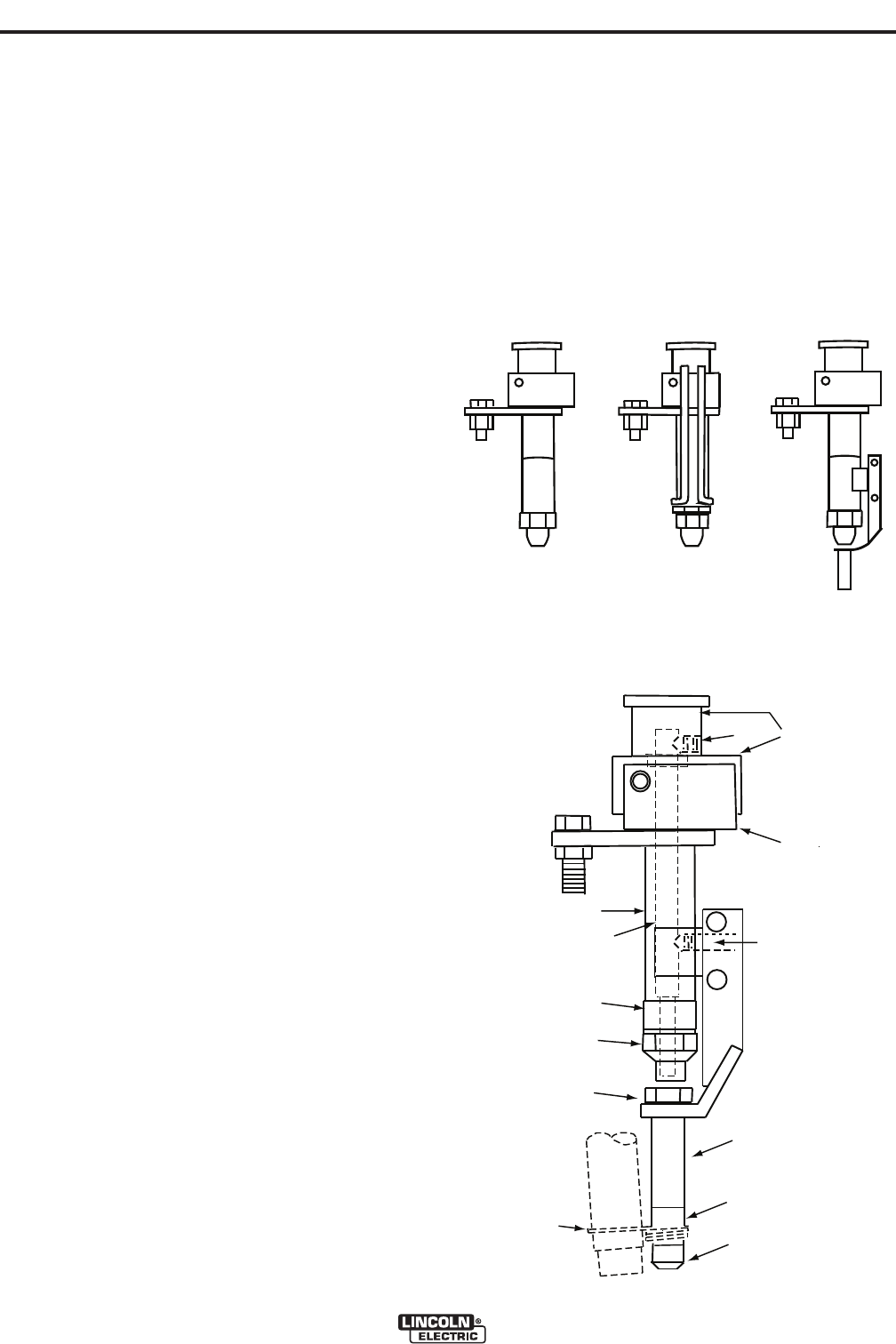

K149 Installation (See Figure C.5)

1. Install the K149 attachment before mounting the

K148 nozzle on the welder.

2. Place a small C-clamp on the spring supporting

members (A) and (B) in such a manner that the

spring can be compressed. Look up into the hole

in the end of contact tip and tighten the C-clamp

until the tang lifts off the surface of the tip.

3. Remove the 3/8” (9.5 mm) set screw (C) in the

body (A).

4. Remove the contact tip clamping nut (D) and the

contact tip.

5. Remove the brass thread protecting collar (E).

6. Remove the dirt shield (F) from the barrel of the

nozzle.

7. Slide the center guide (G) up out of the pivot body

until the tang is above the window.

8. Place the Linc-Fill guide assembly into the nozzle

window, and then lower the center guide tube (G)

back down to its original position.

9. Line up the spot at the top of the center guide tube

(G) with the 3/8” (9.5 mm) tapped hole in the upper

pivot block (A) and put the 3/8” (9.5 mm) set screw

(C) back into the hole and tighten securely.

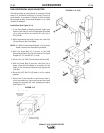

MAXSA™ 22 & 29 WIRE DRIVES

FIG. C.4 - TYPICAL CONFIGURATIONS

K 148 & K 149

K 148

With Water

Cooling

Attachment

K 148

FIG. C.5 - K149 INSTALLATION

A

B

F

G

E

D

11

10

12

13

14

C

H