A-13

INSTALLATION

MAXsa™ 22 & 29 WIRE DRIVES

A-13

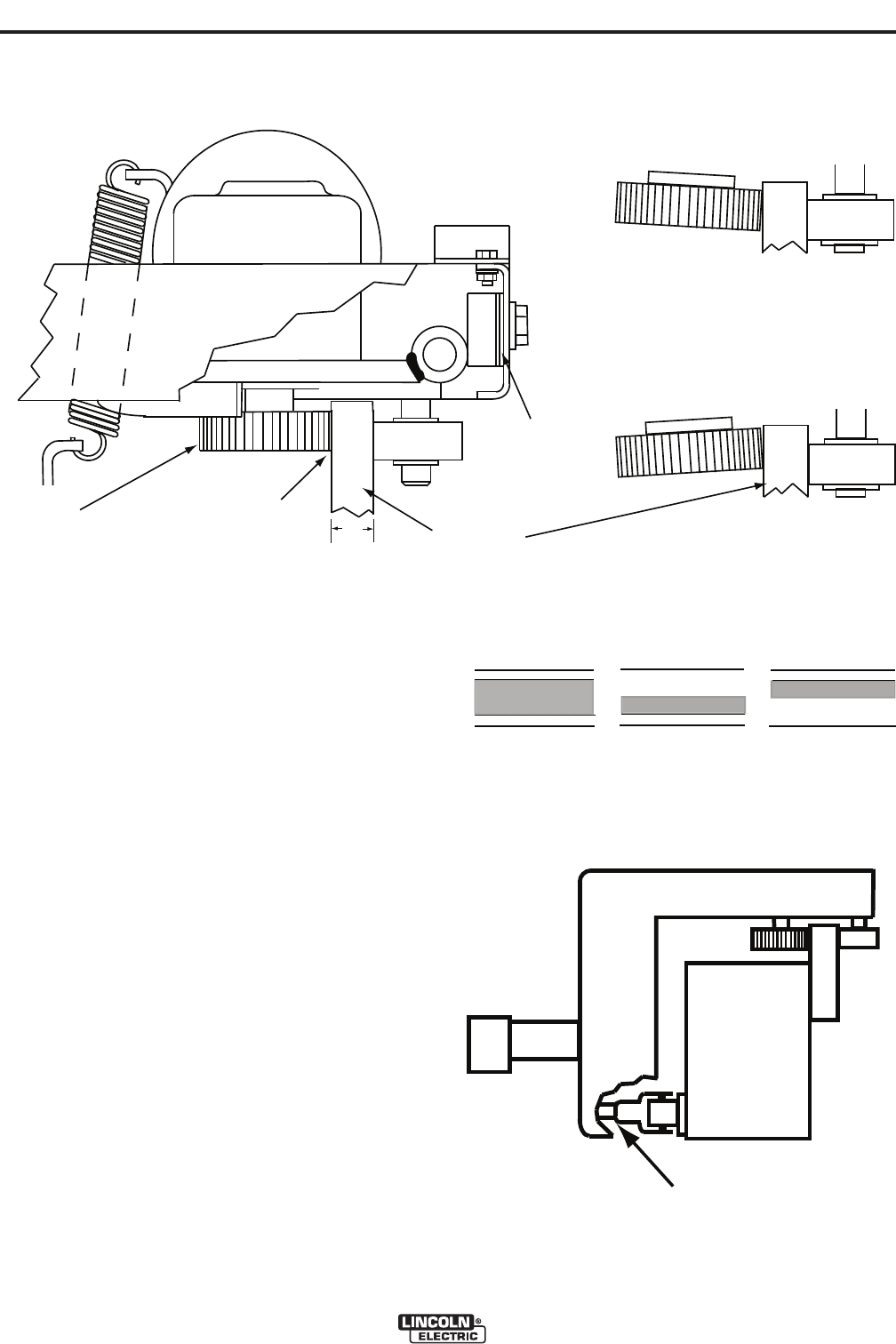

FIGURE A.8 - BEARING TRACKING

INCORRECT PATTERNS

Bearing is not flat

Against Drive Rail

CORRECT PATTERN

Full Face Bearing

Contact

FIGURE A.7 - DRIVE GEAR TRACKING

Beam

Drive Rail

Shims

Full Face

Contact

Drive Gear

Incorrect

ADD Shims

Incorrect

REMOVE Shims

.88”

FIGURE A.9 BEARING SHIMS

Shim Here

DRIVE GEAR TRACKING

The TC-3 is shimmed at the factory so that the drive

gear sits flat against a .88” (22mm) flange when the

release handle is in the up position. If the flange

dimension is other than .88” (22mm) the shims under

the TC-3 gear box mounting will have to be changed

accordingly. See Figure A.7.

NOTE: TC-3 units are shipped with a helical tooth

drive wheel that is suitable for use on a

smooth drive rail. A straight tooth gear

(T13586) is available for use on a drive rail

with a straight cut knurl.

CARRIAGE BEARING TRACKING

Bearing tracking can be checked by placing a strip of

white paper over the area where the bearings ride.

With the drive gear disengaged (handle down), move

the carriage over the strips. If the tracking is correct

the bearings will leave a uniform trace on the paper.

See Figure A.8. If traces are not corrrect add shims as

necessary. See Figure A.9.