C-15

ACCESSORIES

MAXsa™ 22 & 29 WIRE DRIVES

C-15

K281 SOLID WIRE STRAIGHTENER FOR

TINY TWINARC

®

The K281 wire straightener can be used to straighten

.045” through 3/32” (1.0-2.4mm) wiress. It is recom-

mended for applications requiring long stickout and/or

where accurate wire placement is essential. The fol-

lowing table shows the recommended maximum ele-

crical stick-out (ESO).

GENERAL INFORMATION

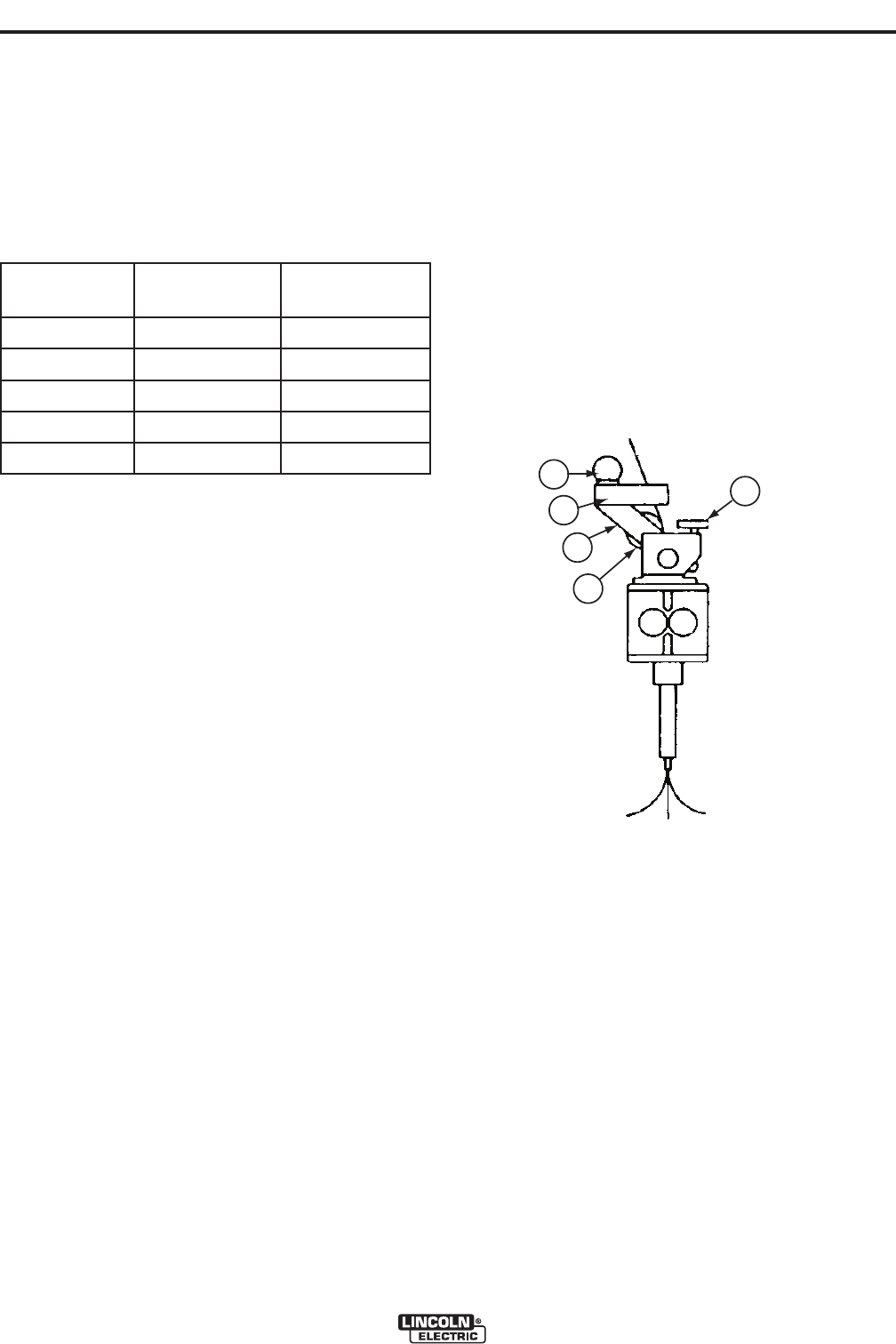

1. For best wire straightening the plane of the

K281rolls (A) should be as close as possible to

the plane of the wire reels.

2. The K281 moving arm (B) should be pointing

toward the wire reels and the adjusting knob (C)

should be away from the reels.

3. The K281 can be mounted to the wire drive in

two different positions. The head can then be

positioned to meet the above requirements.

INSTALLATION

1. Remove the Spring Wire Guide if installed.

2. Remove the K129 Ingoing Guide Tube.

3. Insert the new Ingoing Wire Guide (with ceramic

inserts) that comes with the K281.

4. Position the K281 over the wire guide as outlined

above and tighten the two hex head screws.

WIRE LOADING AND ADJUSTMENT

1. Turn the adjusting knob (C) to the maximum

open position.

2. Remove the top ingoing guide block (D) by loos-

ening the thumb screw (E).

3. Straighten the first 10” (254mm) of each wire (the

straighter the wire the easier to load).

4. Insert one wire through each of the guide block

holes.

5. Push both wires through and between the rollers

and down through the guide tube until they touch

the drive roll(s). Press the Cold Inch to start the

wires through the wire drive.

6. Replace the upper guide block making sure that

each wire is in its respective groove of both

rollers. Tighten the thumb screw.

7. Turn the adjusting knob until the moving arm is

approximately at the mid position of its total trav-

el.

The tips should be in line with the O.D. of the drive

rollsfor initial strightening adjustment. If the wires bow

to the right when inched down through the tips they

are being over straightened. If the wires bow to the

left, they are being understraightened. Adjust the knob

until the wires come out parallel and uniform.

Depending on how the wire enters the K281, there

may be some side bow. Slight rotation of the K281

may eliminate this condition.

Once the wire is sufficiently straight, the tip orientation

can be changed to whatever angle between “in-line”

and “cross seam” is required.

NOTE: For overlay applications with Tiny Twinarc, a

special side by-side tipholder (Part # S17728

is available that accepts standard tips.

Wire Size (mm)

ESO - Standard

Wire Guide (mm)

ESO - K281

Straightener (mm)

.045” (1.0) 3/8” (9.5) 5/8” (16.0)

.052” (1.3) 1/2” (12.5) 3/4” (19.0)

1/16” (1.6) 3/4” (19.0) 1-1/4” (32.0)

5/64” (2.0) 1.00” (25.4) 1-3/4” (44.5)

3/32” (2.4) 1-1/4” (32) 2.0” (51)

FIGURE C.21

E

D

B

A

C

Under

Straightened

Over

Straightened