C-12

ACCESSORIES

MAXsa™ 22 & 29 WIRE DRIVES

C-12

B. For 3/32 (2.4mm) Wire

1. Remove the items listed in Step “A” plus:

• The drive roll key

• The drive roll spacer

NOTE: The set screw that holds the drive roll spacer

in place is accessible once the idle roll assem-

bly is removed.

2. Oil or grease the O.D. of the new shorter drive

roll spacer (E) and place it on the output shaft.

Push it back as far as it will go and tighten the

set screw.

3. Place the new longer key (F) in the keyway.

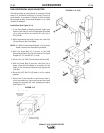

4. Place the outer, center and second outer drive

rolls (A) on the shaft. Replace the clamping

washer and the locking nut and tighten securely.

See Figure C.17.

C. Nozzle Installation

1. install the new idle roll arm (C) using the pin and

set screw from the original assembly. .

2. Replace the tension spring and screw and adjust

the tension screw to the .045-3/32 line on the

indicator plate.

3. Insert one of the guide tubes (B) in the top of the

faceplate. Line up the holes in the guide tube

with the grooves in the drive rolls to insure proper

wire feed

NOTE: If using the K281 Twinarc Wire straightener,

follow the supplied instructions and skip to

Step 5.

4. Put the dual ingoing wire guide (D) over the ingo-

ing guide tube and lock it down with the two “L”

shaped clamps from the wire straightener.

5. Insert the two long insulated wire guides (2) into

the Twinarc nozzle (1) making sure that they are

seated in the holes in the mounting block (7).

Place the contact tip (4) or tip holder (5) into the

end of the nozzle making sure the tubes fit into

the holes. Lock it securely in place with the lock-

ing collar (3). See Figure C.16.

NOTE: For applications that require staggered or

cross seam wire placement rather than in-line,

the contact tip or tip holder may be rotated.

Re-adjust the head position to maintain the

proper wire-to-work angle.

For overlay applications a special “side by

side” tip holder (part# S17728) that accepts

standard contact tips is available.

6. Place the other guide tube (B) into the outgoing

side of the faceplate. Place the nozzle over the

guide tube and lock it in place with the two sock-

et head screws

7. Bolt the electrode cable(s) of the proper size and

number, to the connection tab (6) using the hard-

ware provided. If using multiple cables, use both

sides of the tab.

E. Maintenance

Replace the Contact Tip(s) when they no longer pro-

vide accurate wire placement or good electrical con-

tact. Before installing the new contact tip or tip holder:

1. Make sure that the threads and bottom surface of

the nozzle are clean and bright. These are cur-

rent carrying surfaces and must be clean.

2. Check that the locking collar is free of foriegn

material. A coating of locally available “anti-

seize” compound or graphite grease will help

insure longer thread life.

3. Before replacing the contact tip or tip holder:

a. Inch the wire past the end of the nozzle.

b. Slide the long wire guides on to the wire

making sure they are properly seated in the

mounting block (see Figure C.16).

c. Slide the new contact tip or tip holder over

the wires again making sure that thewire

guides are properly seated

d. Replace the locking collar and tighten

securely

FIGURE C.17

O

utput

Shaft

Drive Roll

Spacer

Key Outer Drive Rolls

C

enter

D

rive Roll

Clamping

Washer

Locking

Nut