D-1

MAINTENANCE

D-1

MAXsa™ 22 & 29 WIRE DRIVES

SAFETY PRECAUTIONS

ELECTRIC SHOCK can kill.

• Only Qualified personnel should

perform this maintenance.

• Turn the input power OFF at the

disconnect switch or fuse box

before working on this equipment.

• Do not touch electrically hot parts.

ROUTINE MAINTENANCE

• Check weld cables, control cables and gas hoses for

cuts.

• Clean and tighten all weld terminals.

• Inspect and clean drive rolls and inner wire guide

and replace if worn.

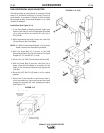

PERIODIC MAINTENANCE

• Every six months check the motor brushes. Replace

them if they are less than 1/4" long.

• Every year inspect the gearbox and coat the gear

teeth with a moly-disulfide filled grease. DO NOT

use graphite grease.

CALIBRATION SPECIFICATION

All calibration is factory set on the MAXsa™ Wire Drive.

To verify the wire feed speed:

• Adjust the wire feed speed to 100 in/min (2.54m/min)

and provide a COLD FEED Signal.

• Measure the actual wire feed speed with a calibrated

wire feed speed tachometer K283).

• The measured wire feed speed should be within ±2%

of the set value.

NOTE: If a K283 is not available, feed wire for 15 sec-

onds and measure the wire. Repeat several

times to get an average measurement. It should

be 25” (635mm) +/-2%.

SENSE LEAD FUSE

There should never be any current flowing through

the sense leads! The sensing lead circuit is current

protected in the Power Wave

®

AC/DC 1000 SD.

If the MAXsa™ 22 & 29 Wire Drives are used in an

older system, a fuse in series with the #21 sense lead

in the wire drive Connection Box protects the sense

lead circuit from weld current due to incorrect configu-

ration. If this fuse ever opens, check the sense lead

configuration to ensure proper connections. The fuse

must be replaced with a comparable fuse with a rating

of less than 1 amp before welding. The fuse being

open or missing would have the same effect on the

welding as having a disconnected sense lead.

WARNING