C-6

ACCESSORIES

MAXsa™ 22 & 29 WIRE DRIVES

C-6

To install a new contact tip proceed as follows:

1. Clip the end of the electrode and inch it up until it is

free of the tip.

2. Remove the contact tip locking nut.

3. Relieve the spring pressure of the contact tip against

the steel tang in the hole of the contact tip. To do

this, push the nozzle body so the steel tang is

approximately centered in the 3/8” (9.5 mm) hole in

the contact tip. Under these conditions the contact

tip can be easily removed from the nozzle body.

4 a. Before installing the new tip, make sure the

threads and the bottom surface of the nozzle are

clean and bright. These surfaces are current car-

rying areas and must be clean.

b. Push the nozzle body to one side to relieve the

pressure and insert the new contact tip.

5. a. Check the locking ring threads making sure

they are free or any foreign material. A small

application of locally available high temperature

anti-seize compound or graphite grease on

these threads insure a longer thread life of the

two mating parts.

b. Replace the locking ring and tighten securely.

6. Check the contact tip to be certain it is tight in the

nozzle body. If the tip is not tight, arcing will take

place between the tip contact surface and the noz-

zle contact surface which will damage the nozzle

body.

K285 Concentric Flux Cone

The K285 Concentric Flux Cone is designed to fit on a

K148 (with or without the K149 attachment) or on a

K129 Tiny Twin-Arc® nozzle. This attachment

deposits the flux so that it surrounds the electrode(s).

NOTE: If using a K149 extension, the electrical stick-

out will be limited to 4” (102mm).

The K285 consists of two pieces that are electrically

isolated from each other. The stationary segment is

clamped to the nozzle and the moveable portion

which supports the flux hose and the concentric cone

allows for vertical adjustment of the flux cone.

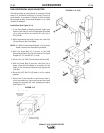

K285 Installation to the K148

1. Remove the tension on the center guide tube using

a “C” clamp as shown in Figure C.8. Apply only

enough clamping force to relieve the tang pressure

from the contact tip.

2. Remove the contact tip clamping nut and the con-

tact tip.

3. Remove the brass thread protecting collar and

slide the dirt shield off of the nozzle.

4. Make sure that all the threads are clean and

replace the collar, the contact tip and the clamping

nut and remove the “C” clamp.

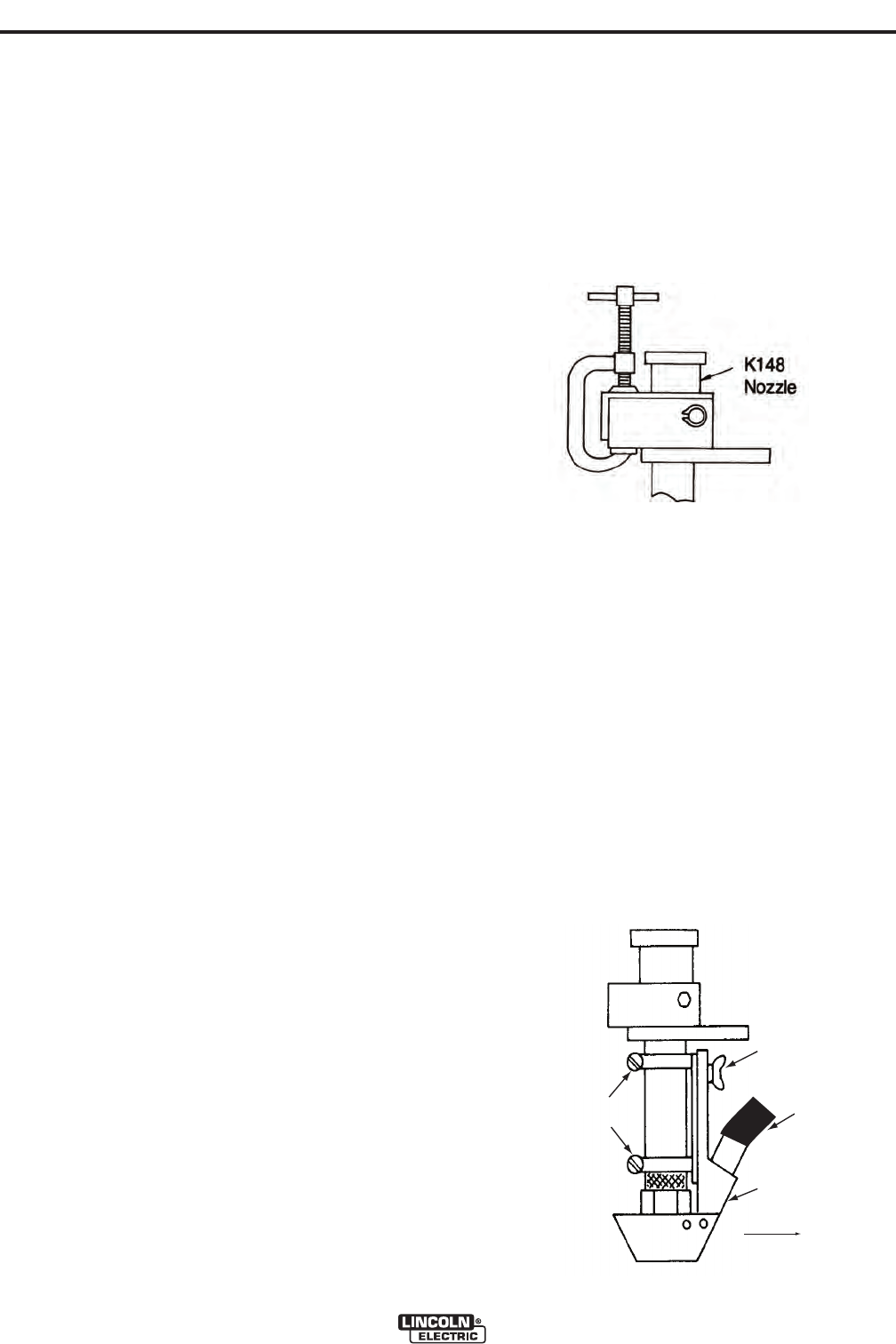

5. Loosen the hose clamps of the K285 entirely, place

them around the nozzle and tighten them so that

the stationary part of the K285 covers the opening

in the nozzle body as shown in Figure C.9.

6. Position the moveable section to the desired flux

height and tighten the wing nut.

7. Cut the flux hose to required length and connect as

shown.

FIGURE C.8

FIGURE C.9 - K148

Travel

Direction

Wing Nut

Hose

Clamps

Flux

Hose

Moveable

Section