C-3

ACCESSORIES

C-3

K226 CONTACT ASSEMBLY

The K226 assemblies are used for welding at currents

from 600 to 1000 amps.

Model K226-T - (2 tapered jaws)

3/32” and 1/8” (2.4 and 3.2mm) electrode

Model K226-R - (1 tapered and 1 rectangular jaw)

1/8” thru 7/32” (3.2 - 5.6mm) electrode

Installation - Remove the two nozzle mounting

clamps from the wire drive. Insert the outgoing

wire guide from the wire feed head into the top of

the K226 and install the assembly in position on

the bottom of the wire feed head. Use the two

screws provided with the K226 to attach it to the

wire drive. See Figure C.3.

NOTE: Removing the 4 screws that hold the noz-

zle body to the mounting block allows the

nozzle to be rotated to any of four posi-

tions 90° apart. See Figure C.3.

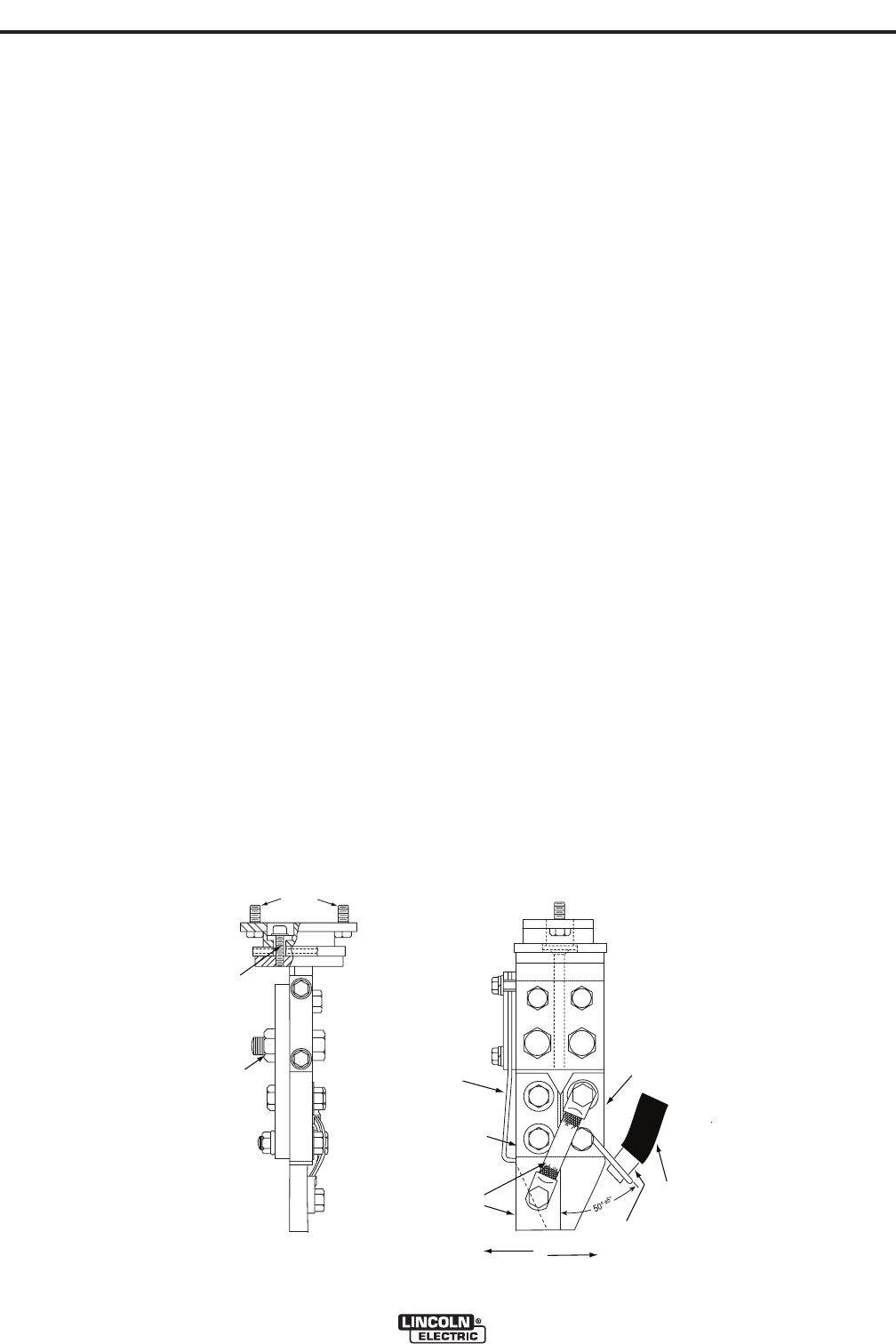

Connect two (2) electrode cables to the contact

jaws (one under each 1/2-13 nut. Make sure that

the cable lugs are flat against the copper and

tighten the nuts securely. See Figure C.3.

Slip the rubber flux hose that comes with the

K226 on to the flux hopper valve. Fit the copper

tube into the other end and place it in the clip on

the lower jaw assembly. See Figure C.3.

Maintenance - Rusty or dirty wire and/or exces-

sively high welding currents increase wear on the

contact jaws. When arcing occurs or the elec-

trode becomes loose in the jaws, remove the

jaws and ʻdressʼ them with a file. When neces-

sary, the jaw inserts should be replaced.

NOTE: Units made prior to 1979 did not have

inserts. The replacement jaws will have

them.

The contact jaws must be kept in line with the

wire guide. Align the jaws as follows: (See Figure

C.3)

1. Loosen the stationary contact jaw screws.

2. Release the tension on the moveable jaw by

loosening the screws holding the spring.

3 Place a straight 14” (or longer) piece of bare

5/32” (4.0mm) wire through the wire guide

and into the drive rolls of the feed head.

4. Adjust the stationary contact so the wire

touches the jaw at the center of the groove

for the entire length of the jaw.

5. Tighten the screws, remove the wire and re-

tighten the screws holding the spring to

apply tension to the moveable jaw. The

moveable jaw should move freely when fin-

ished.

MAXSA™ 22 & 29 WIRE DRIVES

FIGURE C.3 - K226 CONTACT NOZZLE ASSEMBLY

Use to Mount

to Wire Drive

Remove(4)

Screws to

Rotate Nozzle

Attach Weld

Cables Here

K226-R

Only

Flux

Hose

Copper Tube

WORK

TRAVEL

NOZZLE

TRAVEL

Spring

Stationary

Contact

Moveable

Contact