INSTALLATION

A-4 A-4

MULTI-SOURCE

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

FUSE AND WIRE SIZES

Protect the input circuit with the super lag fuses or

delay type circuit breakers listed on the Technical

Specifications page of this manual for the machine

being used. They are also called inverse time or ther-

mal/magnetic circuit breakers.

DO NOT use fuses or circuit breakers with a lower amp

rating than recommended. This can result in nuisance

tripping caused by inrush current even when machine

is not being used for welding at high output currents.

Use input and grounding wire sizes that meet local

electrical codes, or see the Technical Specifications

page in this manual.

INPUT AND GROUNDING

CONNECTIONS

Note: A qualified electrician should connect the

input power supply leads.

Input conductor is brought into the machine input box

area through a hole in the rear panel sized to accom-

modate 2" (trade size) conduit and fittings. This is more

than adequate for the largest conductors required.

Conductors must be lugged to attach to the three 3/8"

studs on the input reconnect panel and the 5/16"

ground stud marked with the symbol . The input volt-

age supplied determines the position required for the

reconnect panel jumper. The three ranges on the stan-

dard machine are 380-415, 440-460 and 550-575. The

machine is rated for 50 and 60 Hz operation. See the

Input Connection Diagram located on the inside of

Case Back Input Access Door.

The conductor and fuse sizes in the Technical

Specification Section), are per the National Electrical

Code. The sizes are in American Wire Gauge (and the

next largest standard metric size in mm

2

). National and

local codes must be consulted before connecting a

machine.

Protect the input circuit with the super lag fuses or

delay type circuit breakers listed in the Technical

Specification Section. (They are also called inverse

time or thermal / magnetic circuit breakers.)

RECONNECT PROCEDURE

Multiple voltage machines are shipped connected to

the highest input voltage listed on the machine’s rating

plate. Before installing the machine, check that the

Reconnect Panel in the Input Box Assembly is con-

nected for the proper voltage.

Failure to follow these instructions can cause immedi-

ate failure of components within the machine.

-----------------------------------------------------------

To reconnect a multiple voltage machine to a different

voltage, remove input power and follow the input

Connection Diagram located on the inside of the Case

Back Input Access Door. This connection diagram is

shown below.

CAUTION

WARNING

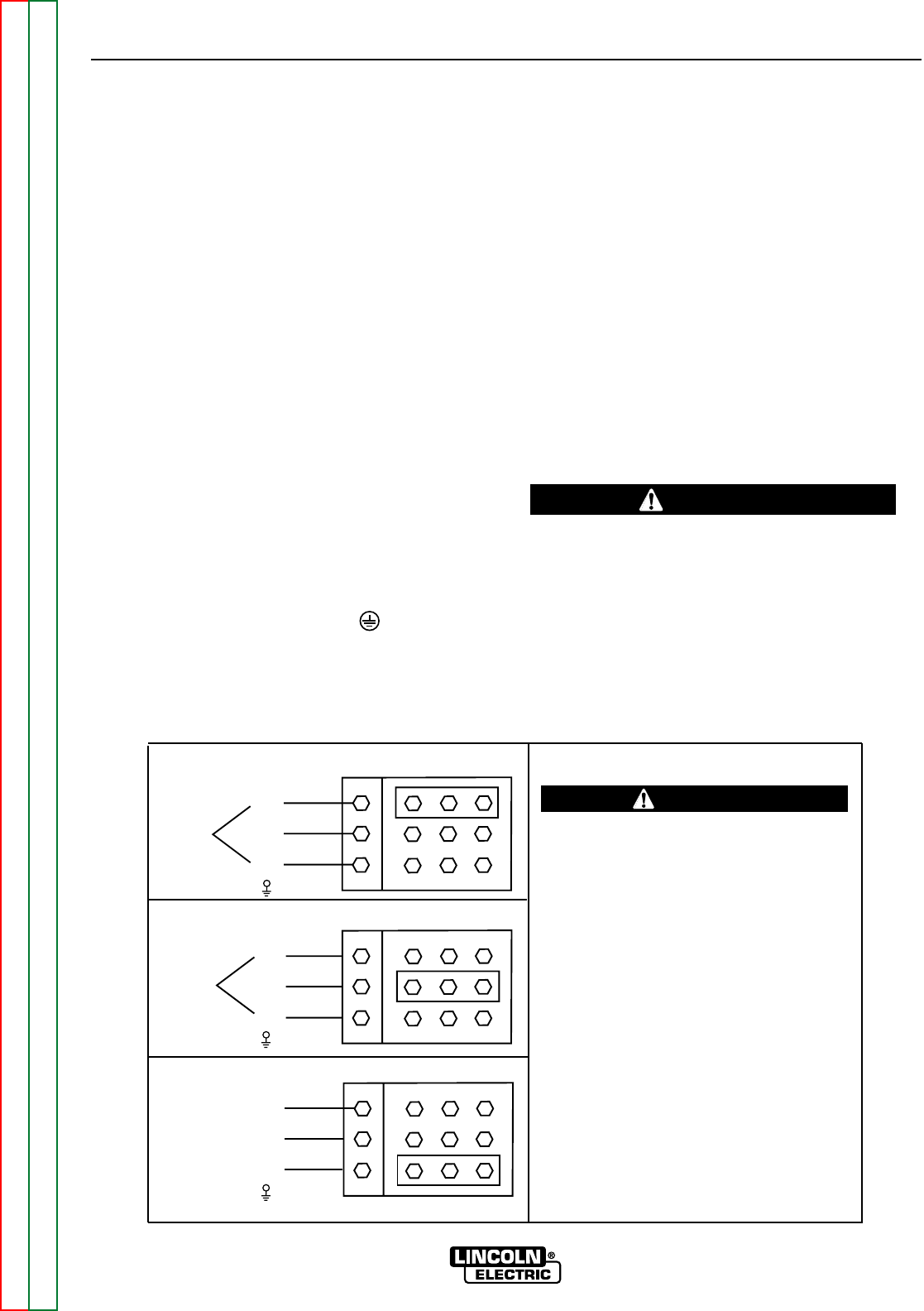

FIGURE A.3. - Input Connection Diagram

All input power must be electrically discon-

nected before touching reconnect panel.

1. Mount the movable reconnect bar to

the stationary reconnect panel as

shown, and secure firmly with the

three hex nuts provided.

2. Connect L1, L2, and L3 input supply

lines to the input side of the recon-

nect panel as shown.

3. Connect terminal marked to ground

per national electrode code.

550-575V Connection

440-460V Connection

380-415V Connection

INPUT

LINES

L3

L2

L1

W

V

U

INPUT

LINES

L3

L2

L1

W

V

U

INPUT

LINES

L3

L2

L1

W

V

U