F-14 F-14

TROUBLESHOOTING & REPAIR

MULTI-SOURCE

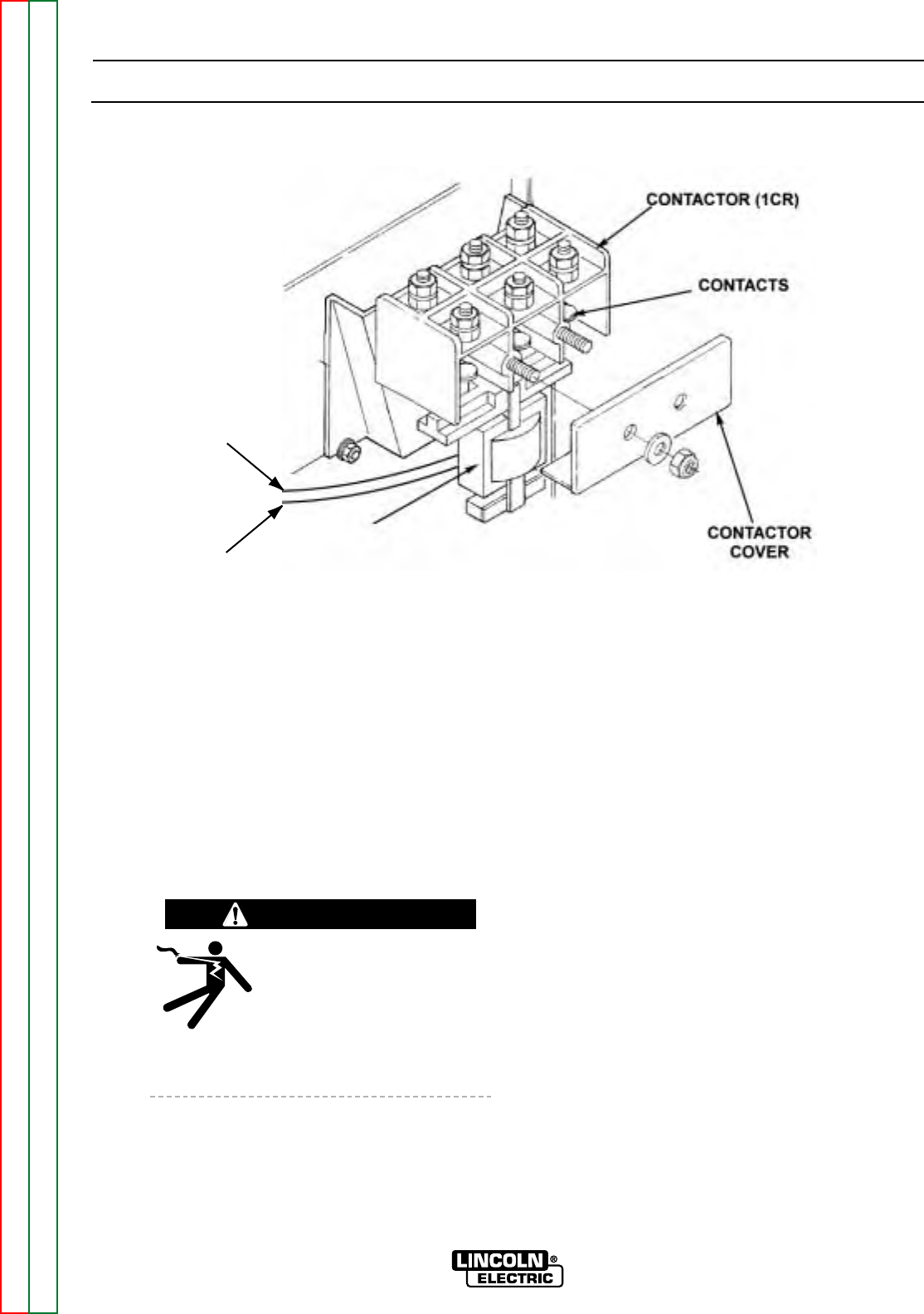

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

INPUT CONTACTOR TEST (Continued)

CONTACTOR

COIL

240

241

1. Disconnect the main input supply power to

the machine.

2. With the 3/8” nut driver, remove the case

top and the left case side.

3. Locate the two leads connected to the

input contactor coil, #240 and #241. See

Figure F.3 for location. Note: The discon-

nects may be located inside the loom (lead

covering).

4. Connect a DC ammeter to either lead #240

or #241.

Electric Shock can kill.

• With the input power on,

there are high voltages inside

the machine. Do not reach

into the machine or touch any

internal part of the machine while the power

is on. High voltage is present at terminals.

5. Carefully apply the correct voltage to the

machine and turn the power switch (S1)

ON.

6. Check for approximately 1 amp of current

flow at the contactor coil. This current is

supplied by the Control Board. NOTE: The

pull-in coil current is designed to be about

5 amps for 100ms occurring about one

second after the power switch is closed.

Without this current pulse, the contactor

will not activate.

If the current is present and the contactor

does NOT activate, then the input contac-

tor coil may be faulty, or the contactor’s

moving parts may be stuck. The normal

coil resistance is approximately 4.0 ohms.

If the 1 amp DC current is NOT present,

check the continuity of the leads between

the contactor and the control board. See

the Wiring Diagram.

The contactor may also be tested by dis-

connecting leads #240 and #241 from the

coil and applying an external 120VAC sup-

ply to the contactor coil. The contactor

should activate.

FIGURE F.3. INPUT CONTACTOR CONNECTIONS

WARNING