OPERATION

B-4 B-4

MULTI-SOURCE

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

RECOMMENDED EQUIPMENT/CONNECTIONS

The Multi-weld 350 (K1735-1) is the recommended means by which to control the MULTI-SOURCE power supply.

Connections between the MULTI-SOURCE and the Multi-weld may be easily made using Twist-Mate male and

female connectors and the K1736-1 Distribution box.

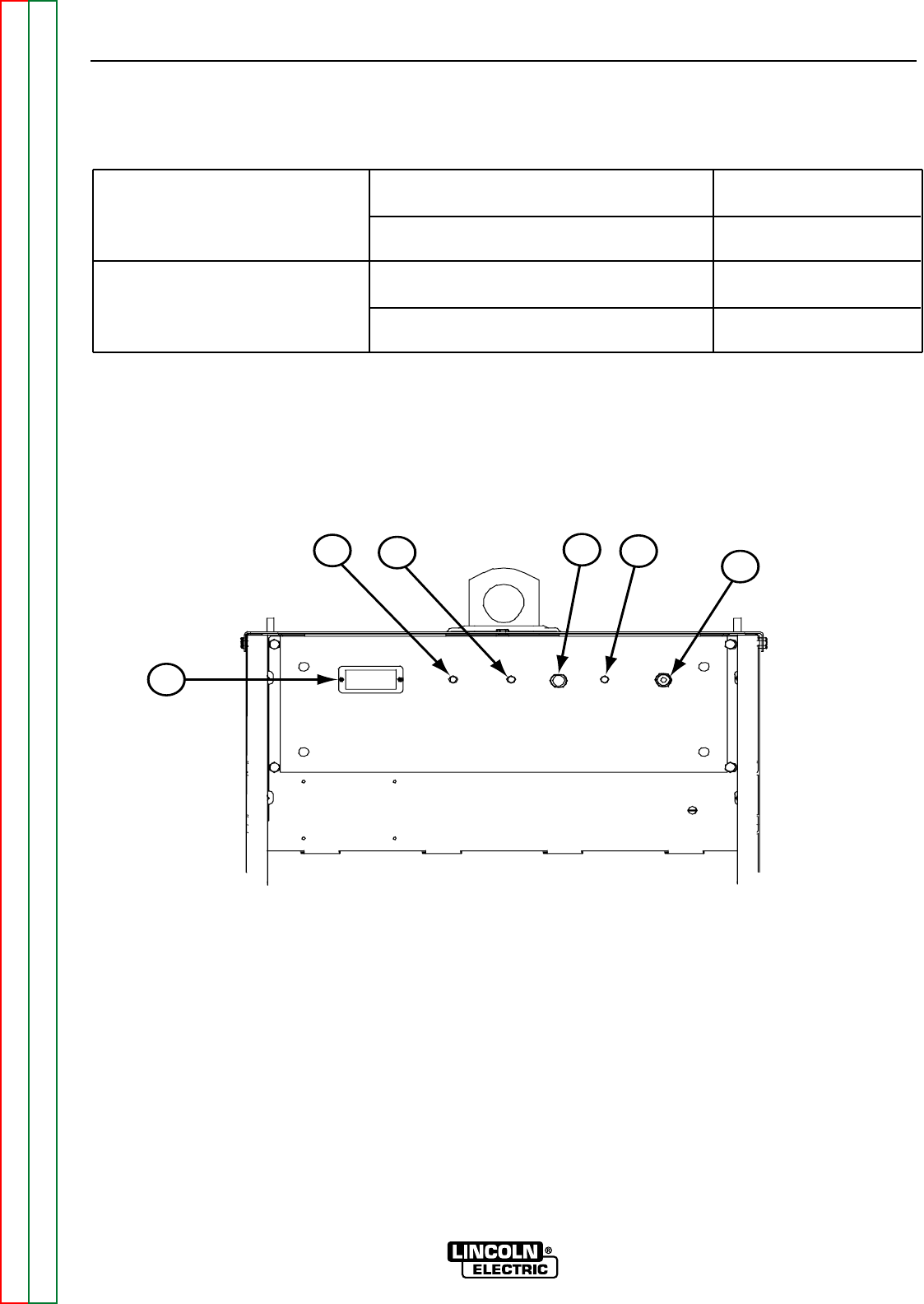

1. ON/OFF TOGGLE SWITCH: This toggle

switch turns the machine ON or OFF.

2. CIRCUIT BREAKER:

This 10 amp

breaker protects the 120 VAC fan circuit.

3. AMBER LED:

This

LED indicates that

the temperature of the machine is too

high.

4. WHITE LED:

This

LED indicates that the

control board is energized.

5. GREEN LED:

This LED indicates that the

machines output voltage is within the safe

operating range.

6. DIGITAL METER: Provides the user with

an indication of the percentage of avail-

able power.

For 1/0 Cable

K852-70

K1759-70

K852-90

K1759-90

Twist-Mate Male Connector

Twist-Mate Female Connector

Twist-Mate Male Connector

Twist-Mate Female Connector

For 3/0 Cable

The Multi-weld 350 has multi-process capability and may be used in manual and semi-automatic processes. When

a wire feeder is required an LN-25 (K449) is recommended. The number of Multi-Weld 350s, the procedures used

and the combined duty cycle of the arcs are only limited by the 40,000 watt (36,000 watts on 50 Hz) rating of the

Multi-Source supply. The machine is IP-23S rated and is designed for outdoor applications.

% Output

Output

Thermal

Fan

Power

On

OFF

6

5

3

2

4

1

CONTROLS AND SETTINGS

All operator controls and adjustments are located on the Case Front Assembly of the MULTI-SOURCE. See

Figure B.1. below for the location of each control.

FIGURE B.1. - CONTROL PANEL