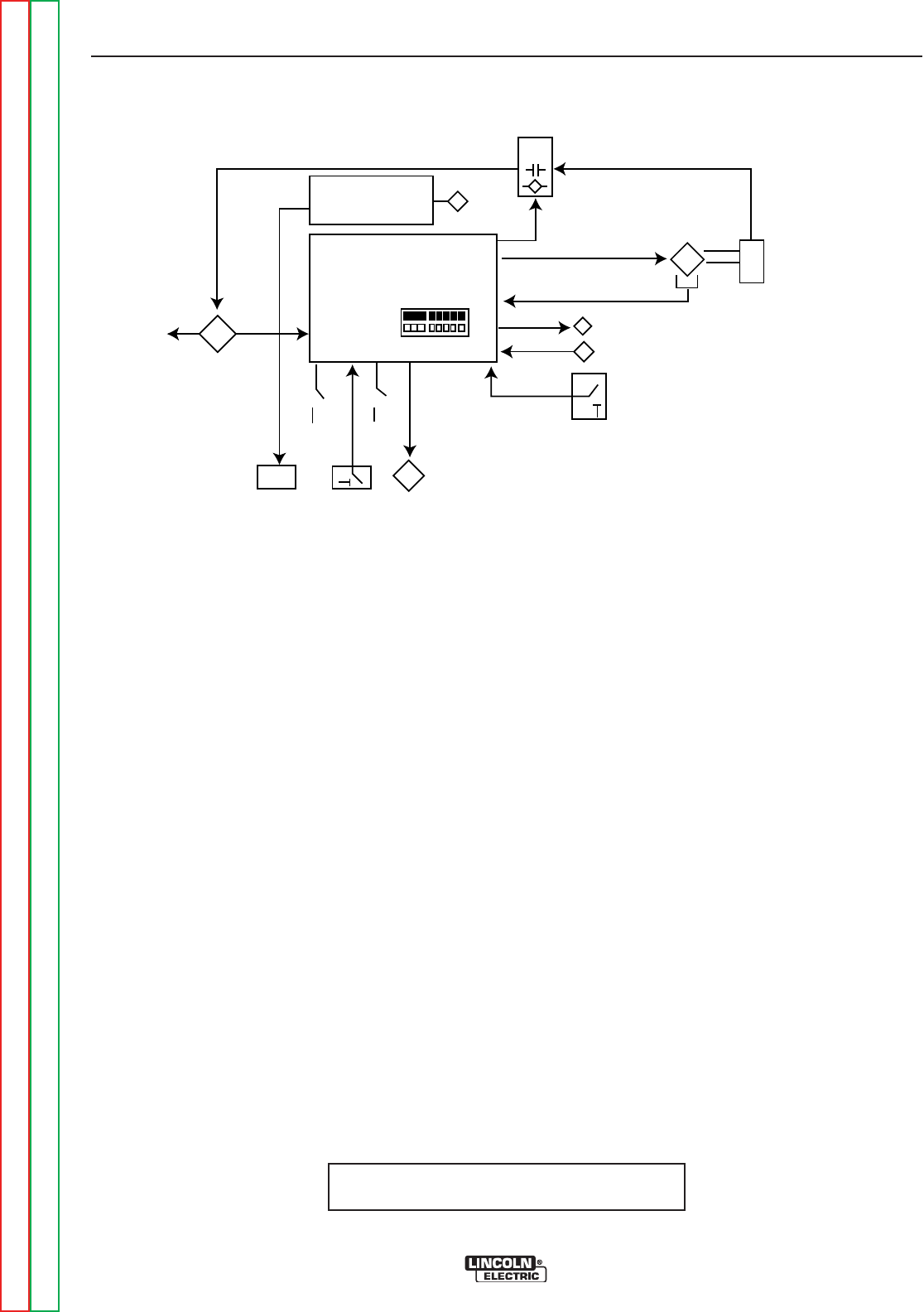

VOLTAGE

SENSE

LEAD #67A

LEAD #67

PUSH PULL

DAUGHTER

DRIVE

MOTOR

GEAR BOX

AND

CONDUCTOR

BLOCK

FEEDBACK

TACH

STATUS LED

GUN TIGGER AND

DUAL PROCEDURE

RECEPTACLE

2-STEP/

4-STEP

CONTROL BOARD

FEEDHEAD

DIP SWITCHES

TO POWER

SOURCE

INPUT

NETWORK

RECEPTACLE

HEATER LIGHT

CONNECTOR

FOOT AMPTROL

COLD

INCH/

GAS

PURGE

GAS

SOLENOID

THEORY OF OPERATION

E-2 E-2

POWER FEED® 25M

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

GENERAL DESCRIPTION

The POWER FEED® 25 Single Wire Feeder is a wire

feeder, consisting of two components - a wire drive

and a control box - are available assembled as a

bench unit or as a boom system. High speed, highly

reliable digital cables connect the components togeth-

er and to the Power Wave power source.

The POWER FEED® 25M Wire Feeder system has the

ability to connect to one power source, use the same

power source.

The powerful two roll wire drive system sets the indus-

try standard for ease of use. Its patented design allows

for tool-less change out of wire guides and drive rolls

greatly reducing set up time.

FIGURE E.2 - GENERAL PHYSICAL DESCRIPTION

GENERAL FUNCTIONAL

DESCRIPTION

• The POWER FEED® 25M Wire Feeder is a highly

versatile wire feeder with easy to use features that

make it easy for the operator to adjust the arc for

specific preferences.

• The new MSP4 panel clearly displays key welding

information. Use the MSP4 panel to quickly adjust

weld settings, arc starting parameters, arc end para-

meters and set-up variables.

• The POWER FEED® 25M Wire Feeder is provided

with an infrared red (IR) port. Transferring welding

settings is accomplished with a common palm com-

puter.

• When the POWER FEED® 25M Wire Feeder is cou-

pled to a Power Wave welding power source, the

result is a welding system with absolutely superior

arc performance.

NOTE: Unshaded areas of Block Logic

Diagram are the subject of discussion