FX Series Programmable Controllers Basic Program Instructions 2

2-2

2.3 How to Read Ladder Logic

Ladder logic is very closely associated to basic relay logic. There are both contacts and coils

that can be loaded and driven in different configurations. However, the basic principle remains

the same.

A coil drives direct outputs of the PLC (ex. a Y device) or drives internal timers, counters or

flags (ex. T, C, M and S devices). Each coil has associated contacts. These contacts are

available in both “normally open” (NO) and “normally closed” (NC) configurations.

The term “normal(ly)” refers to the status of the contacts when the coil is not energized. Using

a relay analogy, when the coil is OFF, a NO contact would have no current flow, that is, a load

being supplied through a NO contact would not operate. However, a NC contact would allow

current to flow, hence the connected load would be active.

Activating the coil reverses the contact status, that is, the current would flow in a NO contact

and a NC contact would inhibit the flow.

Physical inputs to the PLC (X devices) have no programmable coil. These devices may only be

used in a contact format (NO and NC types are available).

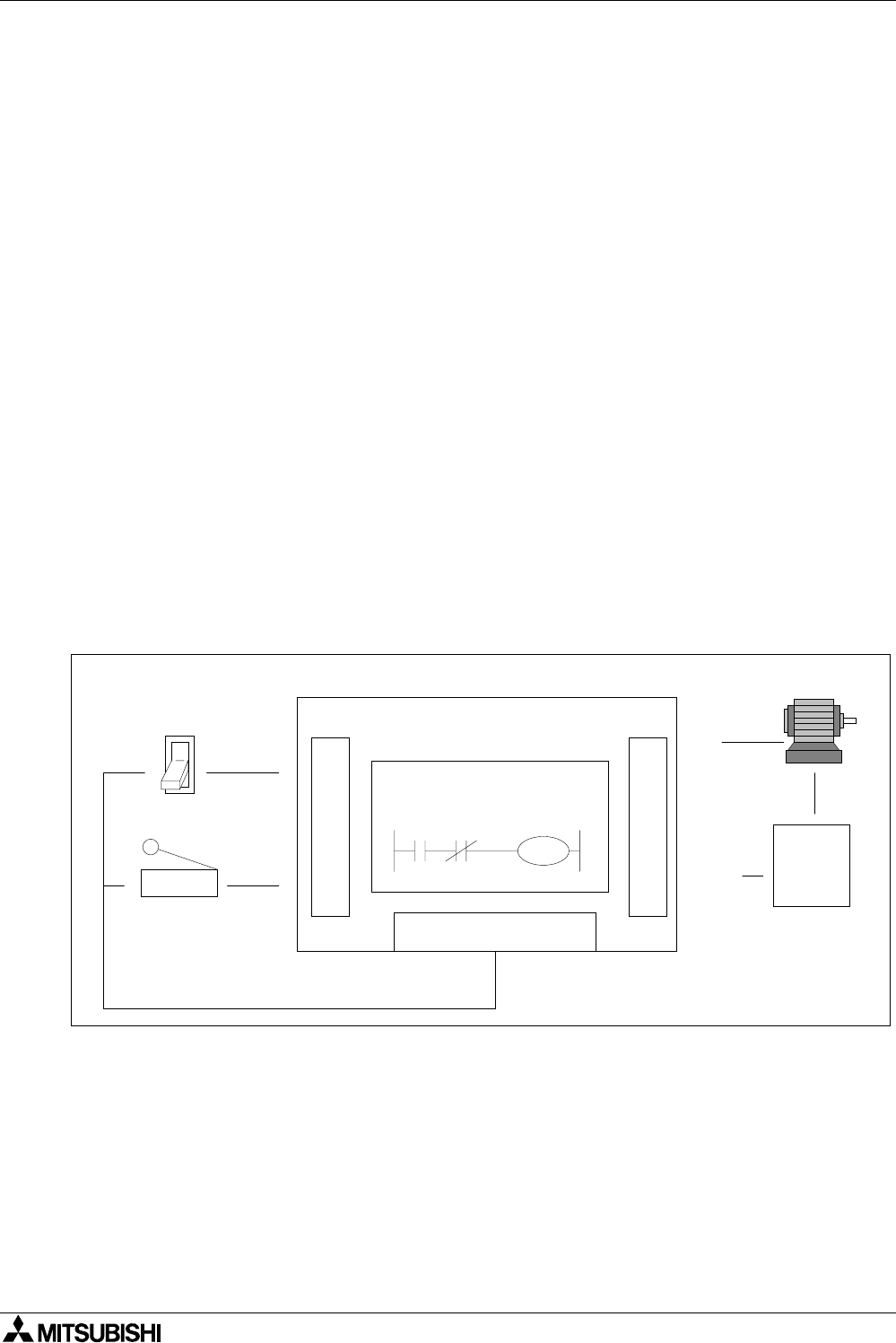

Example:

Because of the close relay association, ladder logic programs can be read as current flowing

from the left vertical line to the right vertical line. This current must pass through a series of

contact representations such as X0 and X1 in order to switch the output coil Y0 ON. Therefore,

in the example shown, switching X0 ON causes the output Y0 to also switch ON. If however,

the limit switch X1 is activates, the output Y0 turns OFF. This is because the connection

between the left and the right vertical lines breaks so there is no current flow.

X0 X1

Y0

PC Program

I

N

P

U

T

O

U

T

P

U

T

Programmable Controller

DC Power Supply

X0

X1

Y0

AC

Power

Supply

COM

(Y0)

Toggle switch

Limit switch

Motor