FX Series Programmable Controllers Basic Program Instructions 2

2-5

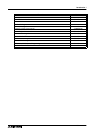

2.5.2 Double Coil Designation

Double or dual coiling is not a recommended

practice. Using multiple output coils of the

same device can cause the program

operation to become unreliable. The example

program shown opposite identifies a double

coil situation; there are two Y3 outputs. The

following sequence of events will occur when

inputs X1 = ON and X2 = OFF;

1.The first Y3 tuns ON because X1 is ON. The

contacts associated with Y3 also energize

when the coil of output Y3 energizes. Hence,

output Y4 turns ON.

2.The last and most important line in this

program looks at the status of input X2.

If this is NOT ON then the second Y3 coil does NOT activate. Therefore the status of the Y3

coil updates to reflect this new situation, i.e. it turns OFF. The final outputs are then Y3 = OFF

and Y4 = ON.

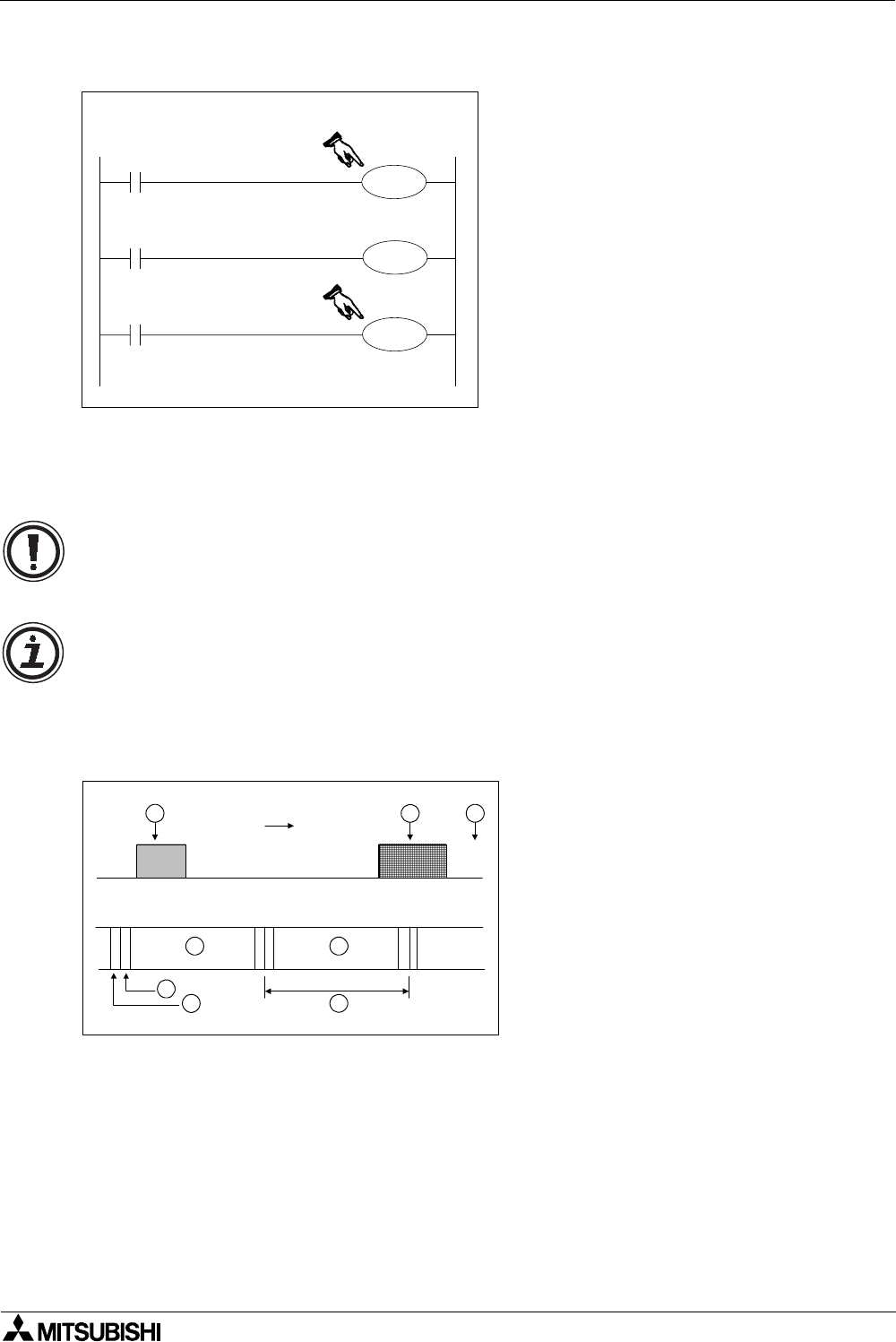

Input durations:

The ON or OFF duration of the PLC inputs

must be longer than the operation cycle

time of the PLC.

Taking a 10 msec (standard input filter)

response delay into account, the ON/OFF

duration must be longer than 20 msec if

the operation cycle (scan time) is 10 msec.

Therefore, in this example, input pulses of

more than 25Hz (1sec/(20msec ON +

20msec OFF)) cannot be sensed.

There are applied instructions provided to

handle such high speed input requests.

: Input ON state NOT recognized

: Input ON state recognized

: Input OFF state NOT recognized

: 1 program processing

: Input processing

: Output processing

: A full program scan/operation cycle

X1

Y3

X2

1.

2.

Y3

Y3

Y4

Use of dual coils:

• Always check programs for incidents of dual coiling. If there are dual coils the

program will not operate as expected - possibly resulting in physical damage.

The last coil effect:

• In a dual coil designation, the coil operation designated last is the effective coil. That

is, it is the status of the previous coil that dictates the behavior at the current point in

the program.

1

2

3

5

6

4

4

7

t secs