FX Series Programmable Controllers STL Programming 3

3-17

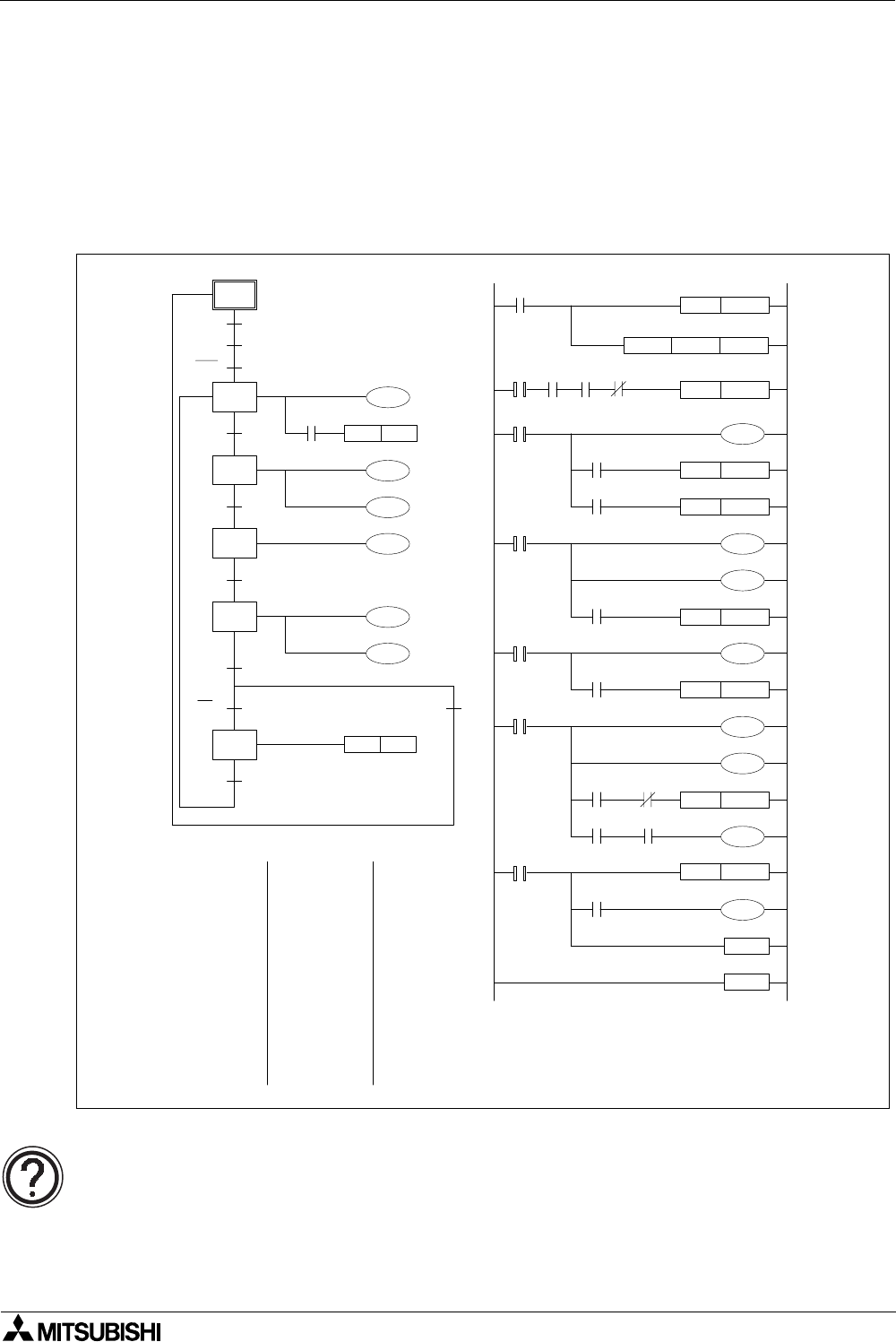

Once at the discharge point the truck opens its bottom doors (Y13). After a timed duration in

which the truck empties its contents, the program checks to see if the repeat mode was

selected on the last cycle, i.e. M2 is reset. If M2 was reset (in state S21) the program ‘jumps’ to

step S21 and the ore truck is returned for immediate refilling. If M2 is not reset, i.e. it is active,

the program cycles back to STL state S0 where the ore truck will wait until the start push

button is given.

This is a simple program and is by no means complete but it identifies the way a series of tasks

have been mapped to an STL flow.

Y10

X1

Y11

X0

T1

Y12

X2

ZRST

S 25

STL

SET S 21

S 21

Y10

RST M 2

X0

STL

S 22

Y11

SET S 23

T1

SET S 22

STL

S 23

Y12

SET S 24

X2

X1

STL

S 24

Y13

T2

M2

STL

S 25

RET

END

STL

S 0

X2X0 Y13

T1

K70

T2

K50

M2

T2

SET S 25

M2

SET M 2

SET S 0

M8002

S 21

S 0

RST

M2

X0

X2

Y13

T1

K70

Y13

T2

K50

M2 M2

SET

M2

M2

2

50

2

2

25

2

2

0

25

2

2

21

OUT

K

LD

ANI

SET

LD

AND

OUT

STL

SET

LD

OUT

RET

END

T

T

M

S

T

M

S

S

M

M

S

1

22

22

11

1

70

1

23

23

12

2

24

24

13

X

S

S

Y

T

T

S

S

Y

X

S

S

Y

LD

SET

STL

OUT

OUT

K

LD

SET

STL

OUT

LD

SET

STL

OUT

8002

0

21

40

25

0

0

2

13

21

21

10

0

2

M

S

S

S

S

X

X

Y

S

S

Y

X

M

LD

SET

ZRST

STL

LD

ANI

AND

SET

STL

OUT

LD

RST

S 21

S 22

S 23

S 24

S 25

T2

S 0

S 21

Identification of normally closed contacts

This example has used the line convention to identify normally closed contacts, for further

variations and different methods used to perform this task please see the information note

page 3-3.