PARAMETERS

135

<Setting>

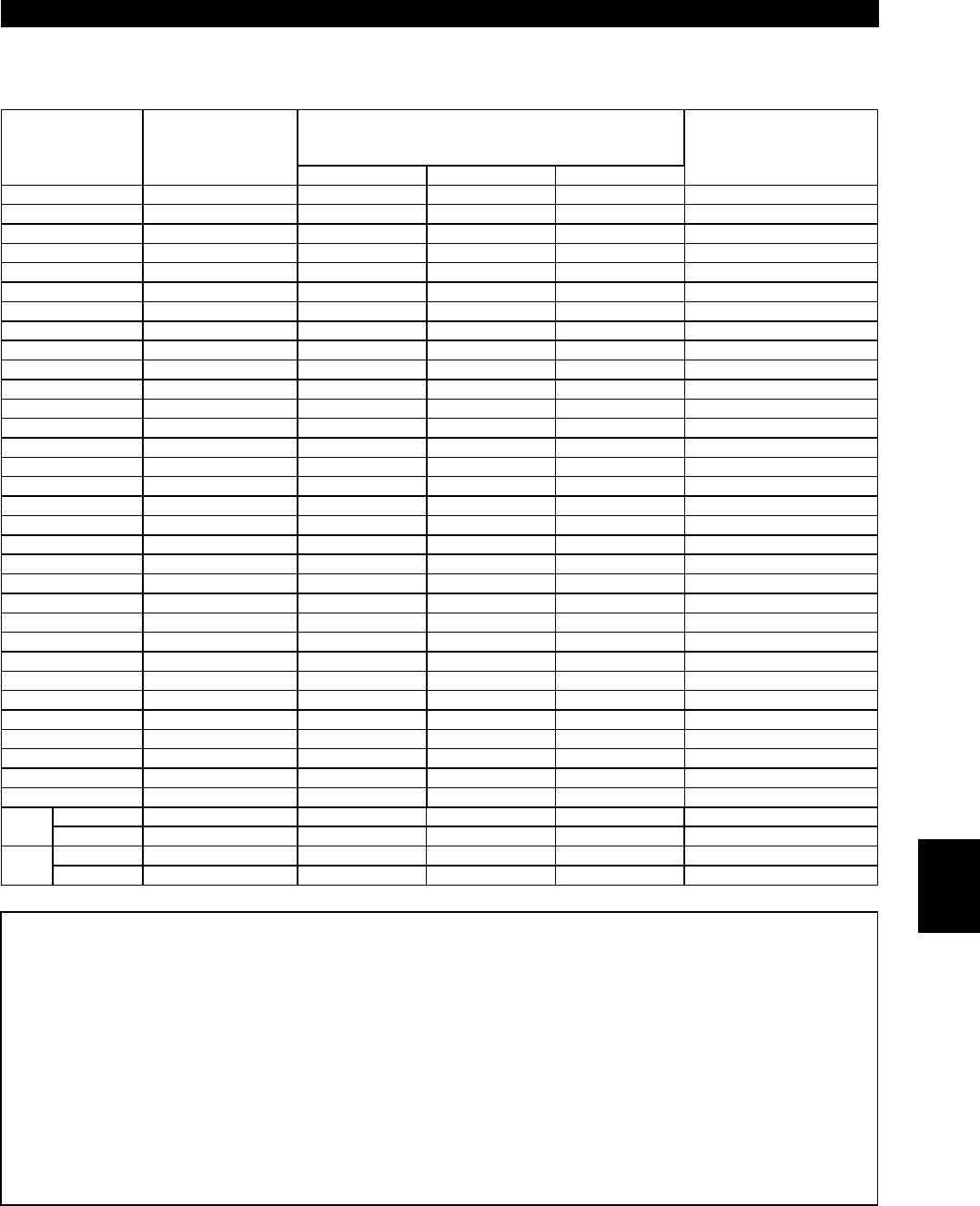

Refer to the following table and set the parameter as required:

Stall Prevention Operation Selection

$

$$

$

...Activated

#

##

#

...Not activated

Pr. 156 Setting

Fast-Response

Current Limit

$

$$

$

...Activated

#

##

#

...Not activated

Acceleration Constant speed Deceleration

OL Signal Output

$

$$

$

...Operation continued

#

##

#

...Operation not

continued (Note 1)

0

$ $$$ $

1

# $$$ $

2

$#$$ $

3

##$$ $

4

$$#$ $

5

#$#$ $

6

$##$ $

7

###$ $

8

$$$# $

9

#$$# $

10

$#$# $

11

##$# $

12

$$## $

13

#$## $

14

$ ### $

15

# ### $

16

$ $$$ #

17

# $$$ #

18

$#$$ #

19

##$$ #

20

$$#$ #

21

#$#$ #

22

$##$ #

23

###$ #

24

$$$# #

25

#$$# #

26

$#$# #

27

##$# #

28

$$## #

29

#$## #

30

$ ### #

31

# ### #

Driving

$$$$ $

100

Regenerative

#### $

Driving

#$$$ $

101

(Note 3)

Regenerative

#### $

Note 1: When "Operation not continued for OL signal output" is selected, the "E.OLT" alarm code

(stopped by stall prevention) is displayed and operation stopped.

(Alarm stop display "E.OLT")

2: If the load is heavy, the lift is predetermined, or the acceleration/deceleration time is short, the

stall prevention may be activated and the motor not stopped in the preset

acceleration/deceleration time. Therefore, set optimum values to the Pr. 156 stall prevention

operation level.

(When the output voltage reduces during stall prevention operation, an overcurrent trip will be less

liable to occur but the torque decreases. Set "0" in Pr. 154 when the torque may be reduced.)

3: At the setting of "101", the fast-response current limit can be disabled in the driving mode as

compared to the setting of "100".

4