INSTALLATION AND WIRING

39

2.3.7 Instructions for compliance with U.S. and Canadian Electrical Codes

(Standard to comply: UL 508C)

(

1

)

Installation

The above types of inverter have been approved as products for use in enclosure and approval tests were

conducted under the following conditions.

•

••

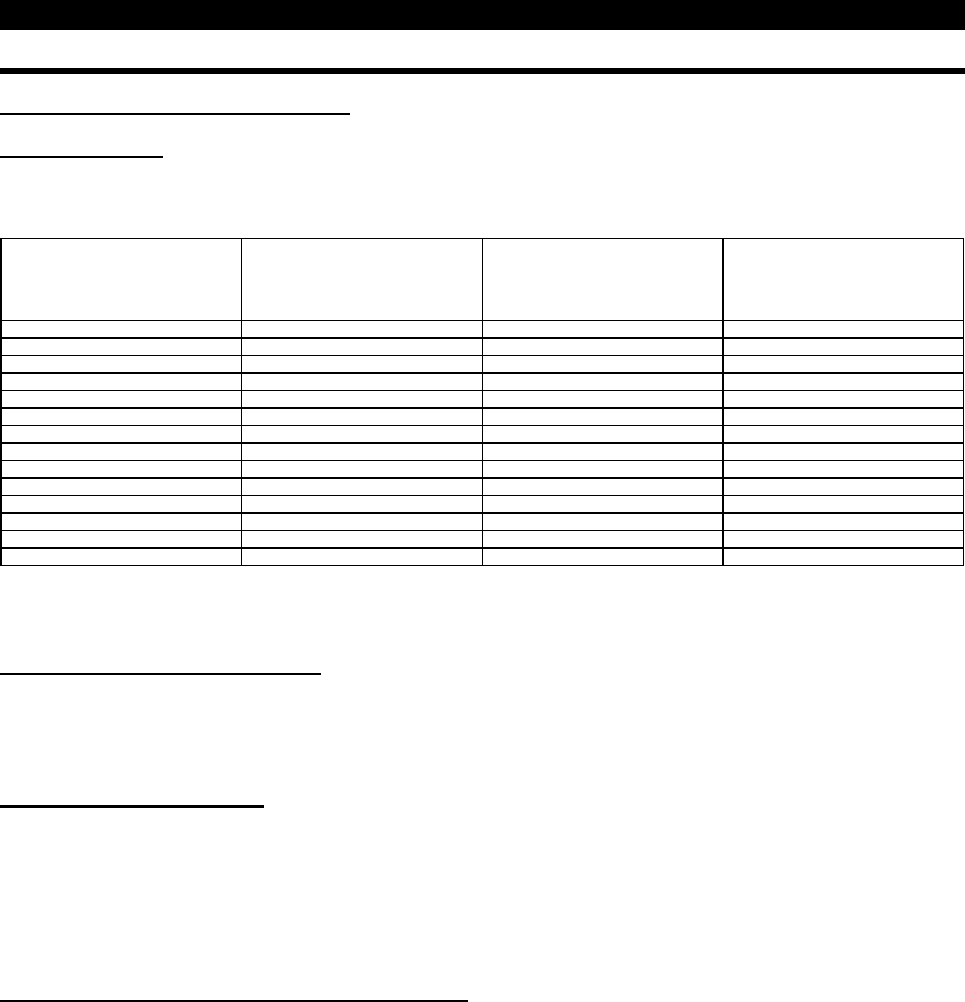

• 200V class

Inverter Model

Minimum Enclosure Volume

(Ratio of enclosure volume to

inverter volume)

Air Vent Area

(Ratio of air vent area in

enclosure top and bottom to

enclosure surface area)

External Cooling Fan

(The following number of

fans of 100cfm wind pressure

are installed 10cm above the

inverter top)

FR-F520-0.75K 150 5.8 0

FR-F520-1.5K 245 1.5 1

FR-F520-2.2K 245 1.5 1

FR-F520-3.7K 245 1.5 1

FR-F520-5.5K 245 1.5 1

FR-F520-7.5K 245 1.5 1

FR-F520-11K 245 1.5 1

FR-F520-15K 370 2.6 2

FR-F520-18.5K 370 2.6 2

FR-F520-22K 370 2.6 2

FR-F520-30K

2

FR-F520-37K

2

FR-F520-45K

2

FR-F520-55K

2

•

••

• 400V class

Design the enclosure so that the ambient temperature, humidity and ambience of the inverter will satisfy the

above specifications. (Refer to page 187)

(

2

)

Branch circuit protection

For installation in United States, branch circuit protection must be provided, in accordance with the National

Electrical Code and any applicable local codes.

For installation in Canada, branch circuit protection must be provided in accordance with the Canada

Electrical Code and any applicable provincial codes.

(

3

)

Short circuit ratings

•

••

• 200V class

Suitable For Use in A Circuit Capable of Delivering Not More Than 5 or 10kA rms Symmetrical Amperes, 230

or 500 Volts Maximum.

•

••

• 400V class

Suitable For Use in A Circuit Capable of Delivering Not More Than 10kA rms Symmetrical Amperes, 500

Volts Maximum.

(

4

)

Wiring of the power supply and motor

Screw the cables wired to the input (R, S, T) <L

1

, L

2

, L

3

> and output (U, V, W) terminals and control circuit of

the inverter to the specified tightening torque using UL-recognized, 75° or higher rated copper wires and

round crimping terminals. Crimp the crimping terminals with the crimping tool recommended by the terminal

maker.