INSTALLATION AND WIRING

42

2.3.9 Earthing (EC version)

(

1

)

Earthing and Earth Leakage Current

(a) Purpose of Earthing

Electrical equipment usually has an Earthing Terminal, this must be connected to earth before using

equipment.

For protection, electric circuits are normally housed inside an insulated case. However it is impossible

to manufacture insulating materials that prevent all current from leaking across them, therefore it is the

function of the earth (safety earth) to prevent electric shocks when touching the case.

There is however, another important earthing function, which is to prevent equipment that uses very

weak signals (Audio equipment, sensors, transducers, etc.) or microprocessors from being affected by

Radio Frequency Interference, (RFI) from external sources.

(b) Points to remember when Earthing

As detailed above there are two entirely different types of earthing and to attempt to use the same

earth for both will lead to problems. It is necessary to separate the “safety” earthing (a yellow/green

wire to prevent electric shocks) from the “FRI” earthing (a braided wire strap to counter radio noise).

The inverter output voltage does not take the form of a sine wave but of a modulated pulse waveform

causing “noisy” leakage current due to the capacitance of the insulation.

The same type of leakage current will occur in the motor due to the charging and discharging of the

insulation from the high frequency waveform. This trend becomes more pronounced with higher carrier

frequencies.

To solve this problem it is necessary to use separate “dirty” earthing for inverter and motor installations

an “clean” earting for equipment such as sensors, computers and audio equipment.

(

2

)

Earthing methods

Two main types of earth

1-To prevent electrical shocks

Yellow and green cable

2-To prevent RFI induced malfunction

Braided strap

It is important to make a clear distinction between these two, and to keep them separate by following the

measures below.

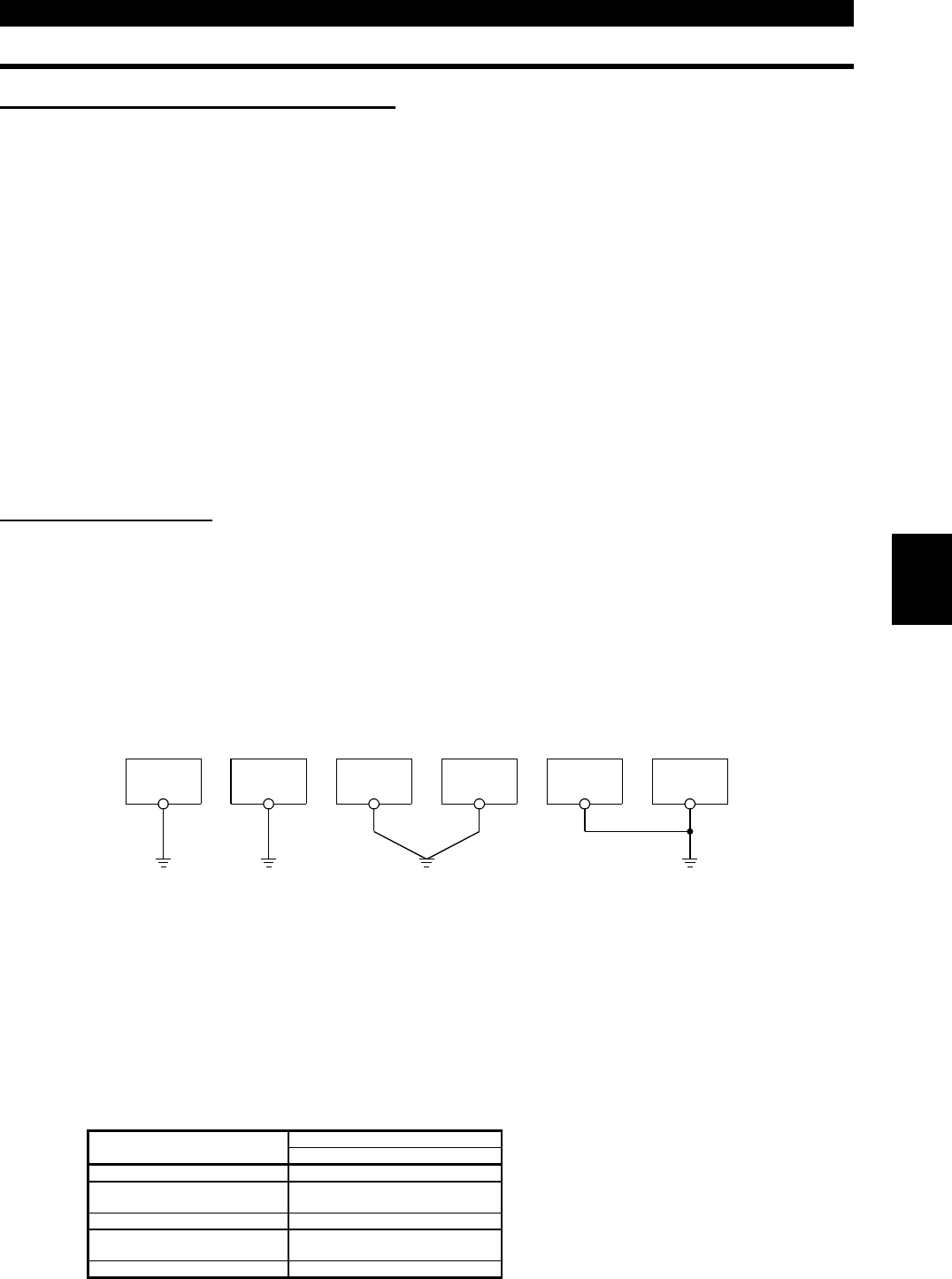

(a) When possible earth the inverter independently of other equipment.

If independent earthing is not possible, use a common earthing point.

Avoid connecting earthing wires together particularly on high power equipment such as motors and

inverters.

Independent earthing should always be used between sensitive equipment and inverters.

Other

equipment

Inverter

(a) Independent grounding

Other

equipment

Inverter

(b) common grounding (c) Grounding wire of

other equipment

Other

equipment

Inverter

(b)Safety earths should be...

For 400V duty - Special class 3, 10

Ω

or less

For 200V duty - Class 3, 100

Ω

or less

(c) The safety earth should be as thick as possible, minimum thickness as stated in below table.

(d)The earthing point should be as close to the inverter as possible, and the wire as short as possible.

(e)The RFI earth should be a braided strap with a 10mm

2

minimum cross sectional area, and as short as

possible.

(f) The earths should be as far away from input and output cables (particularly to equipment sensitive to

RFI) as possible, and any distance where they are parallel should be kept to a minimum.

(g)Design in RFI prevention before installation.

(Unit: mm

2

)

Earth Wire Size

Motor Size

400V Class

3.7kW (5HP) or less 2

5.5kW, 7.5kW

(7.5HP, 10HP)

3.5

11kW to 15kW (15 to 20HP) 8

18.5kW to 37kW

(25 to 50HP)

14

45kW, 55kW (60HP, 75HP) 22

2