RT-PRC031-EN 27

Applications Considerations

Duct Design

It is important to note that the rated

capacities of the air handler can be

met only if the air handler is properly

installed in the field. A well-designed

duct system is essential in meeting

these capacities.

The satisfactory distribution of air

throughout the system requires that

there be an unrestricted and uniform

airflow from the air handler

discharge duct. This discharge

section should be straight for at least

several duct diameters to allow the

conversion of fan energy from

velocity pressure to static pressure.

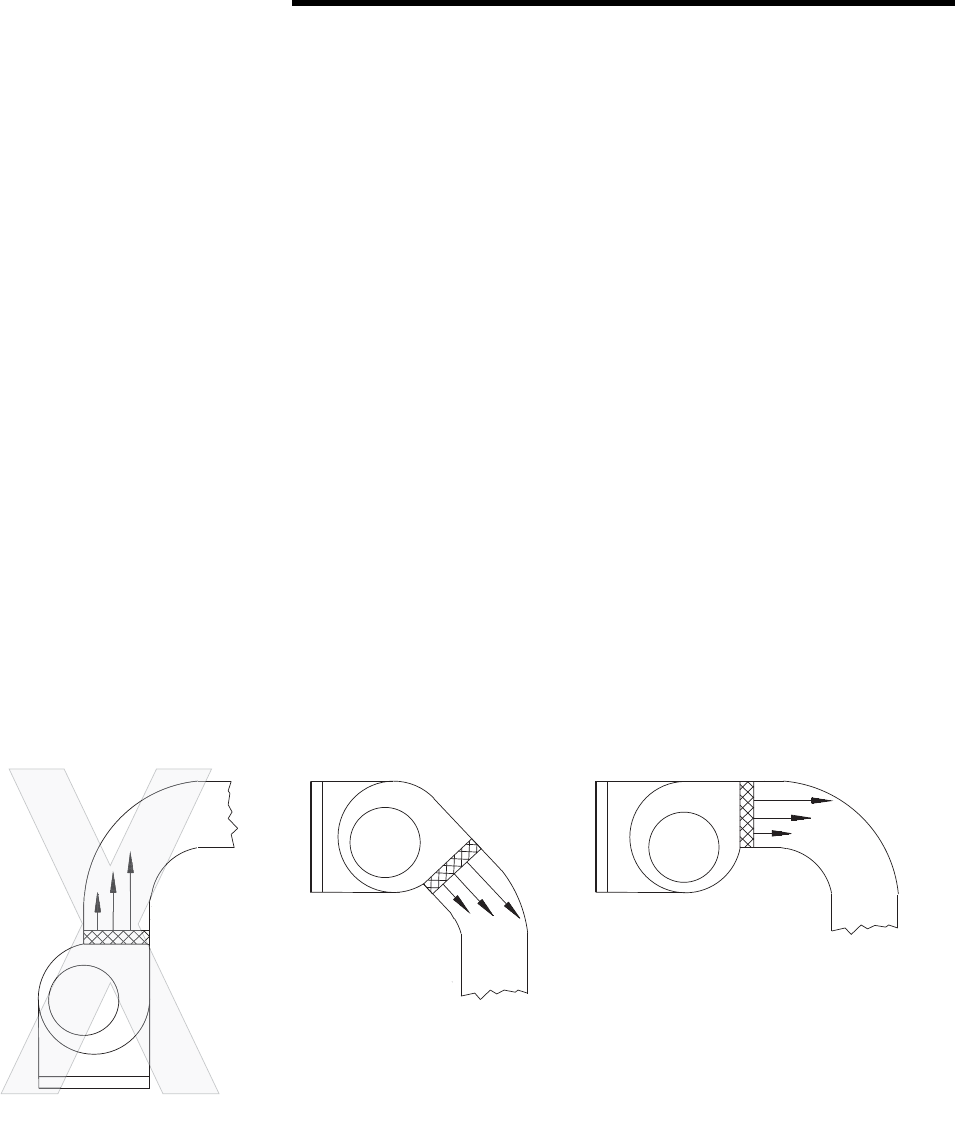

However, when job conditions

dictate elbows be installed near the

air handler outlet, the loss of capacity

and static pressure may be reduced

through the use of guide vanes and

proper direction of the bend in the

elbow. The high velocity side of the

air handler outlet should be directed

at the outside radius of the elbow

rather than the inside as illustrated in

Figure 16, p. 27.

Figure 16. Duct Design

IMPROPER

PROPER

Protecting Hydronic Coils

From Freezing

Taking in outdoor air to satisfy

Standard 62’s ventilation

requirement increases the likelihood

of air stratification. If a layer of air

below freezing moves through the air

handler, it can damage unprotected

hydronic cooling and heating coils.

When a dangerously low air

temperature is detected by the low-

limit thermostat on the entering-air

side of the coil, it will trip. That

triggers the water valve to fully open,

the supply fan to stop, the outdoor

air damper to close and ultimately

degrades the building’s indoor air

quality.

Two options that can be

implemented to continue taking in

outdoor air and avoid coil damage or

tripping the low-limit thermostat

include:

• Draining the coils

• Adding glycol to the cooling

system water to lower its

freezing point

External Piping Enclosure

Space inside the piping enclosure

limits the ability to house control

valves and actuators along with coil

supply and return piping.