30 RT-PRC031-EN

Selection Procedure

Exhaust Fan Motor Sizing

The exhaust/return fan is selected

based on total return system

negative static pressure and exhaust

fan CFM. Return system negative

static includes return duct static, and

any other job site applicable static

pressure drop.

Return duct static pressure = 0.30

inches.

Total return system negative static

pressure = 0.30 inches.

Exhaust fan CFM = 36000 CFM

From Table 39, p. 77 the required

BHP is 21.44 BHP at 400 RPM. Thus,

the exhaust fan motor selected is 25

HP.

To select a drive, enter Table 37, p. 75

for a 25 HP motor and air handler

"C". Drive selection number 4 - 400

RPM.

Return Fan Motor Sizing

The same static pressure and CFM

considerations must be taken for

return fan size, horsepower, and

drive selection as are required for

exhaust fan sizing. However, since

the return fan runs continuously the

sensible heat generated by the return

fan motor must be included in the

entering evaporator coil mixed air

temperature equation.

In this selection, if the return motor

BHP is equal to the exhaust motor

BHP, 21.44 BHP = 58.1 MBH x 1000÷

(1.085 x 36000 Return CFM) = 1.5°F

added to the return air temperature.

Where altitudes are significantly

above sea level, use Table 6, p. 37,

Table 7, p. 37 and Table 8, p. 37 for

applicable correction factors.

Unit Electrical Requirements

Selection procedures for electrical

requirements for wire sizing amps,

maximum fuse sizing, and dual

element fuses are given in the

electrical service section of this

catalog.

Altitude Corrections

The air handler performance tables

and curves of this catalog are based

on standard air (.075 lbs/ft). If the

airflow requirements are at other

than standard conditions (sea level),

an air density correction is needed to

project accurate unit performance.

Figure 18, p. 37 shows the air density

ratio at various temperatures and

elevations.

The procedure to use when selecting

a supply or exhaust/return fan at

elevations and

temperatures other than standard is

as follows:

1. First, determine the air density

ratio using Figure 18, p. 37.

2. Divide the static pressure at the

nonstandard condition by the air

density ratio to obtain the

corrected static pressure.

3. Use the actual CFM and the

corrected static pressure to

determine the fan RPM and BHP

from the performance tables or

curves.

4. The fan RPM is correct as

selected.

5. BHP must be multiplied by the

air density ratio to obtain the

actual operating BHP.

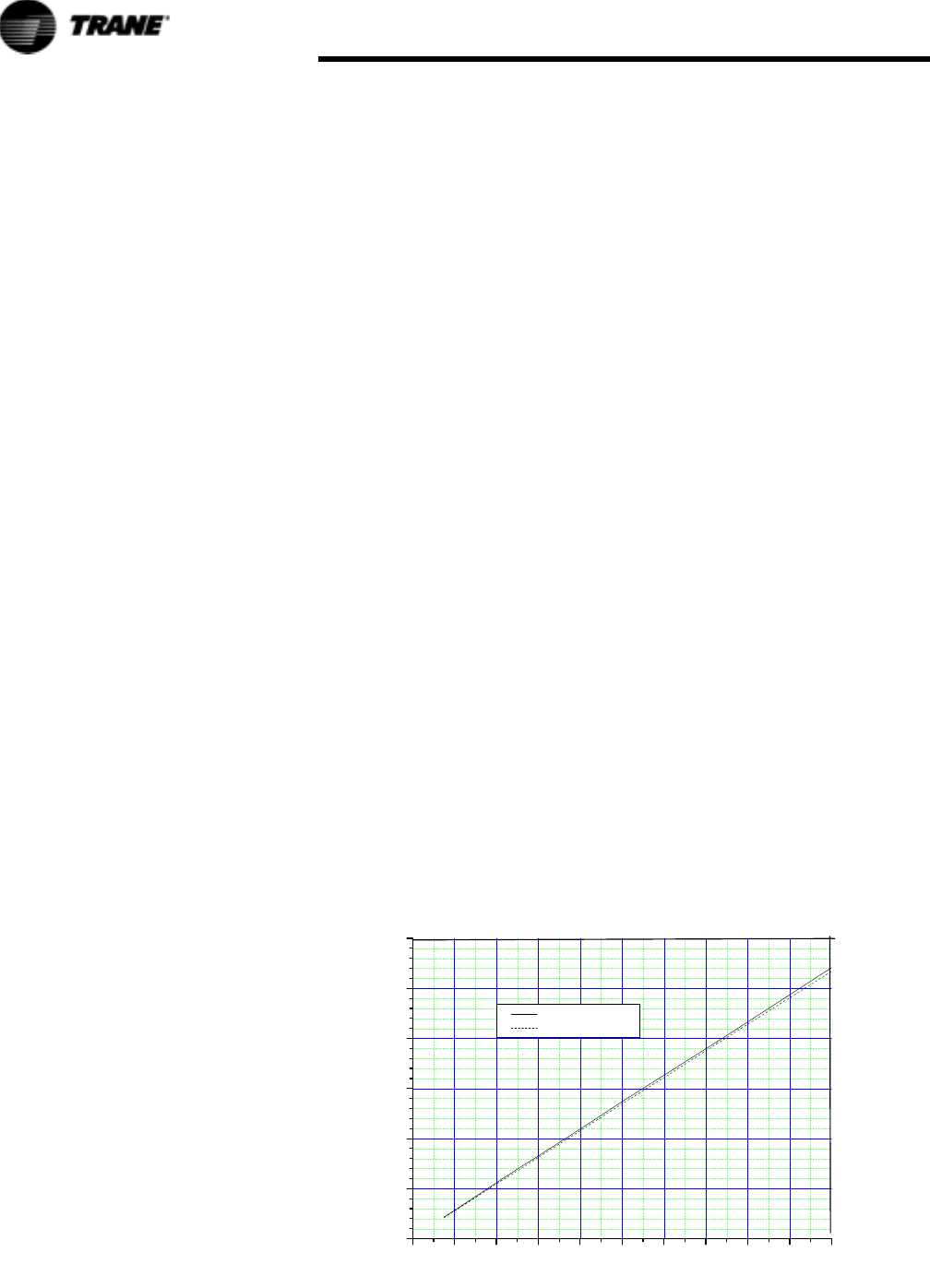

Figure 17. Fan Motor Heat

0 102030405060708090100

0

50

100

150

200

250

300

PM1206

FAN MOTOR HEAT

Std Motor

Hi Efficiency Motor

Fan Motor Heat MBH

Motor Brake Horse Power

In order to better illustrate this

procedure, the following example is

used:

Consider an air handler"C" that is to

deliver 32000 actual CFM at 3-inches

total static pressure (tsp), 55°F

leaving air temperature, at an

elevation of 5000 ft.

1. From Figure 18, p. 37, the air

density ratio is 0.86.

2. Tsp = 3.0-inches / 0.86 = 3.49

inches tsp.

3. From fan performance Table 17,

p. 48 air handler"C" (without inlet

vanes) will deliver 32000 CFM at

3.49 inches TSP at 997 RPM and

30.27 BHP.

4. The RPM is correct as selected -

997 RPM.

5. BHP = 30.27 x 0.86 = 26.3 BHP

actual.

Cooling coil MBH should be

calculated at standard and then

converted to actual using the

correction factors in Table 6, p. 37,

Table 7, p. 37, Table 8, p. 37. Apply

these factors to the capacities

selected at standard CFM so as to

correct for the reduced mass flow

rate across the condenser.

Heat selections other than gas heat

will not be affected by altitude.

Nominal gas capacity (output) should

be multiplied by the factors given in

Table 8, p. 37 before calculating the

heating supply air temperature.