Dual Servo Spin Welder User’s Manual

Dukane Manual Part No. 403-570-01Page 98

Pin Signal Description Function

1 Top-Of-Stroke Status Output ON when press is at Top-of-Stroke position

2 Vacuum On Output, Part Pickup ON when welder calls for vacuum to be turned ON with Part Pickup mode

enabled

3 Bad Part Status Output ON when weld process is outside dened limits with Bad option enabled

4 Suspect Part Status Output ON when weld process is outside dened limits with Suspect option enabled

5 Vacuum On Output, No Part

Pickup

ON when welder calls for vacuum to be turned ON with Part Pickup mode

disabled

(signal is deactivated if idle time between cycles is more than 5 minutes; one of

the RUN SWITCHES must be turned on to reactivate signal)

6 Ready Status Output ON when welder is ready to initiate a weld cycle

7 Output Common Output Common connection

8 Fixture Clamp 1 (Right) Output Function depends on conguration:

Without slide or In/Out slide: ON at start of cycle; OFF at end of cycle

With Left/Right slide: ON at start of cycle when slide is commanded to move to

In (Right) position; OFF at the end of cycle.

9 Fixture Clamp 2 (Left) Output Function depends on conguration:

Without slide or In/Out slide: not used

With Left/Right slide: ON at start of cycle when slide is commanded to move to

Out (Left) position; OFF at the end of cycle

10 Spare Output 2 Not Used

11 Spare Output 3 Not Used

12 Vacuum On Sense Input Activate when sufcient vacuum in upper tool has been detected

13 Automation Start Input Activate to initiate a weld cycle (500 ms min.) with Start Type set to Automation

14 Input Common Input Common Connection

15 Spare Input 1 Not Used

5 4 3 2 1

6

10

15 14 13 12 11

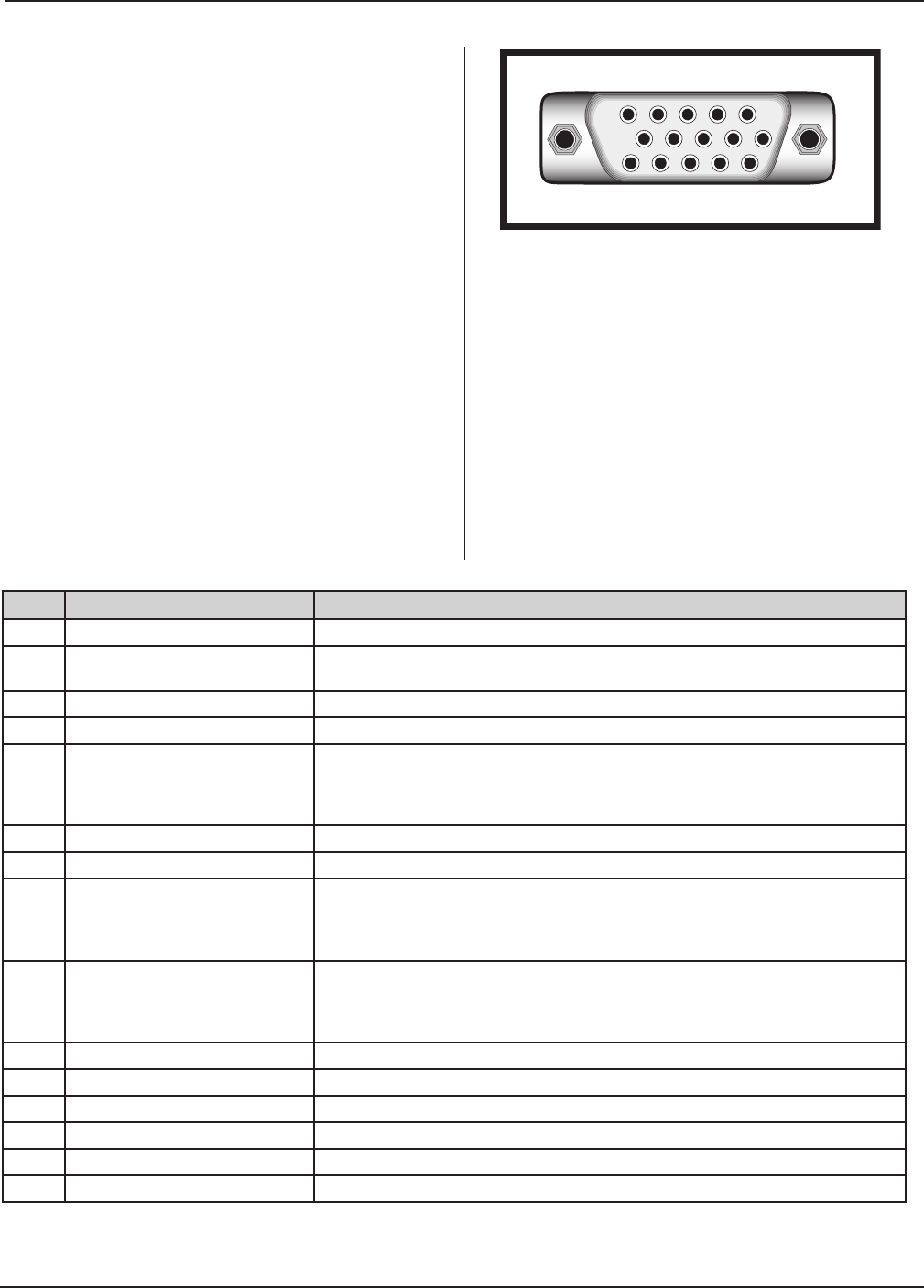

User I/O Connector

The User I/O connector is a HD–15 connector located

directly above the base interface connector on the

rear of the thruster. The connector is shown in Figure

3–8. This connector provides access to signals for

interfacing to custom automation equipment. The pin

numbers for the connector are shown in Figure A–2.

The pin assignments and signal descriptions are given

in Table A-II.

Input signals, such as Vacuum On Sense, can be

congured as sourcing or sinking using 24 VDC and

Input Common. For example, to activate the Vacuum

On Sense input, connect Input Common to ground and

provide 24VDC on the input pin.

Outputs, such as Ready Status, are provided through

relays rated at 1A@24VDC. Outputs provide contact

closure to Output Common when active.

Table A-II Pin Assignments and Signal Description

for the User I/O Connector

Figure A–2 User I/O Connector