Dual Servo Spin Welder User’s Manual

Dukane Manual Part No. 403-570-01Page 34

The Move To button is used to rotate the tool to the value

displayed in the Position (Deg.) eld. After pressing this

button, activate both RUN switches and wait for the

value in the Jog Pos. (Deg.) eld to match the Position

(Deg.) value

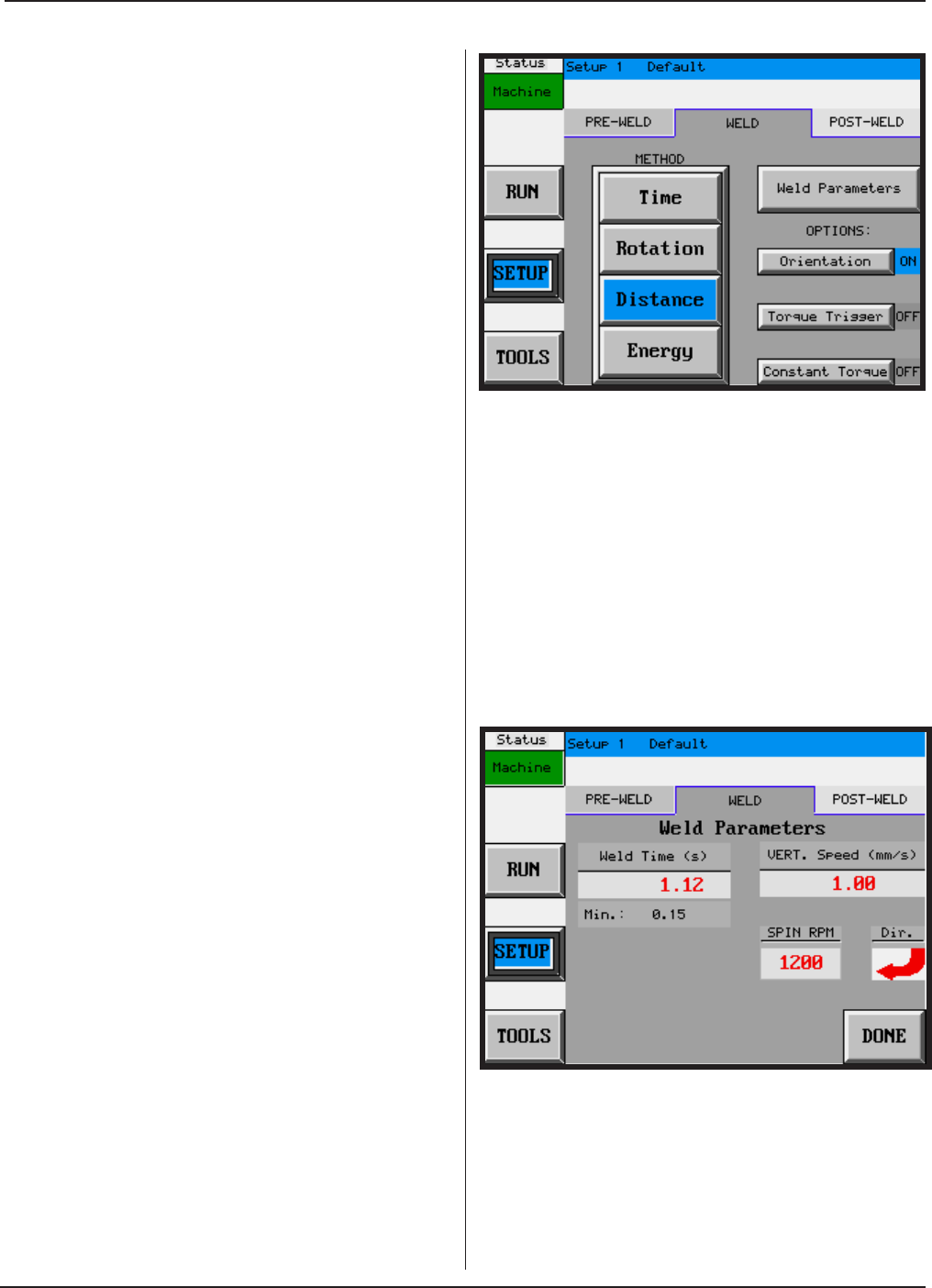

WELD Setup

The WELD setup is the middle tab in the SETUP menu

and is shown in Figure 5-11. This screen contains the

weld METHOD selection (Time, Rotation, Distance, and

Energy), a button for entering Weld Parameters, and

settings for several OPTIONS related to the weld phase

(Orientation, Torque Trigger, and Constant Torque).

Weld Method Selection

One of the available modes must be selected to perform

a weld. Regardless of the method, the weld is considered

to start at different points, depending on the Torque

Trigger option setting. If Torque Trigger is OFF, the

weld starts at the Trigger Position dened in the PRE-

WELD tab. If Torque Trigger is ON, the weld starts

when the desired spin torque threshold is exceeded (see

Torque Trigger Option below).

Time Method

In this method, the weld duration is controlled by time.

After choosing this method, the Weld Parameters

button is used to enter the weld settings shown in

Figure 5-12. The Weld Time (s) entry species the weld

duration in seconds. Below this entry, a minimum weld

time value is displayed. This value corresponds to the

time needed for decelerating (i.e., slowing down and

stopping) the servo motors and is included as part of the

total weld time. The VERT. Speed (mm/s) sets the press

weld speed in millimeters per second. The SPIN RPM

species the spin tool speed, which is constant during

the weld until the start of deceleration. The Dir. eld

species the spin direction. The DONE button causes a

return to the main WELD tab screen.

Figure 5–11 WELD Main Setup Screen

Figure 5–12 Weld Parameters Screen for Time

Method