L100 Inverter

Configuring

Drive Parameters

3–39

Output Function Adjustment Parameters

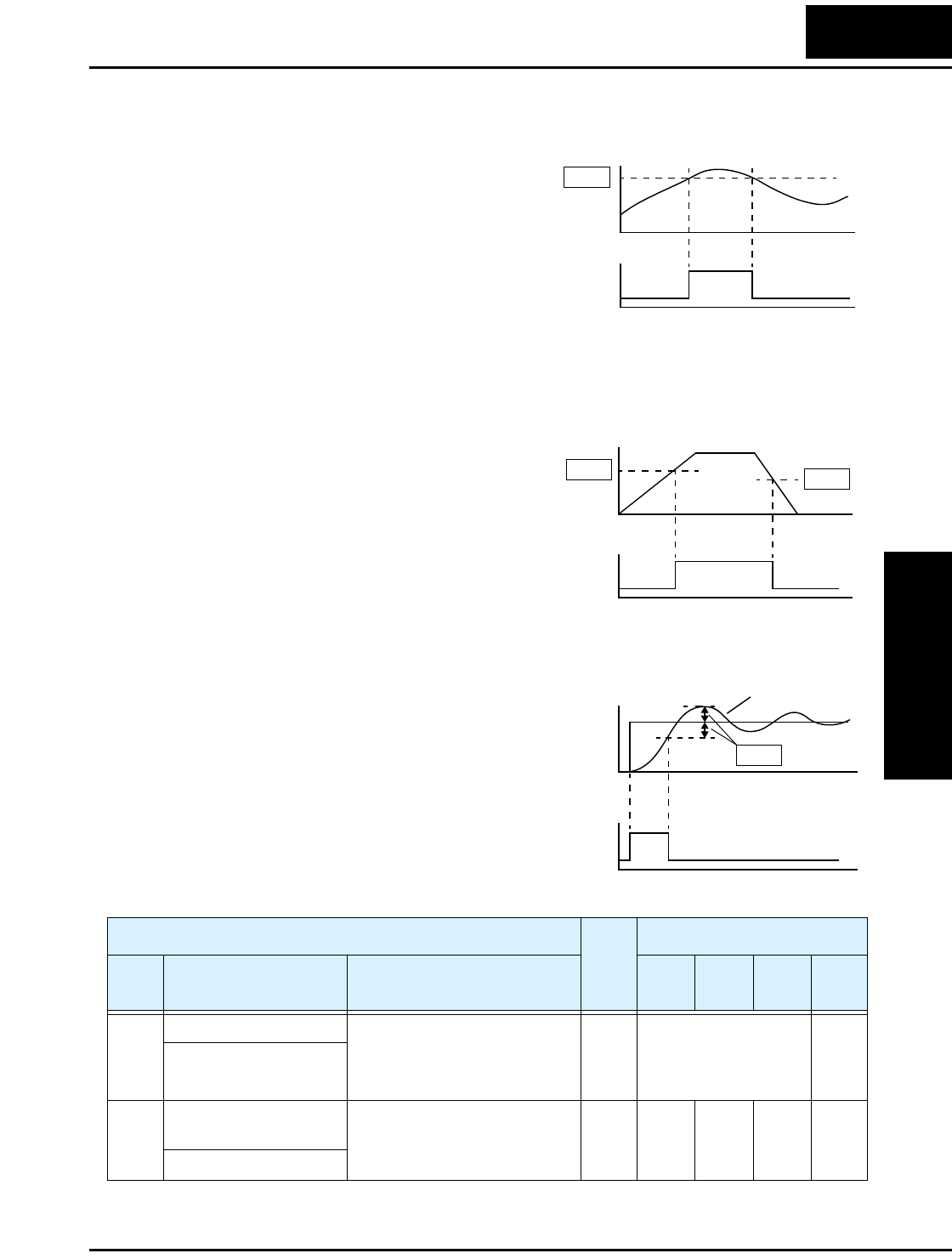

The following parameters work in

conjunction with the intelligent output

function, when configured. The overload

level parameter (C_41) sets the motor

current level at which the overload signal

[OL] turns ON. The range of settings is

from 0% to 200% of the rated current for

the inverter. This function is for generating

an early warning logic output, without

causing either a trip event or a restriction

of the motor current (those effects are

available on other functions).

The frequency arrival signal, [FA1] or

[FA2], is intended to indicate when the

inverter output has reached (arrived at) the

target frequency. You can adjust the timing

of the leading and trailing edges of the

signal via two parameters specific to accel-

eration and deceleration ramps, C_42 and

C_43.

The Error for the PID loop is the magni-

tude (absolute value) of the difference

between the Setpoint (desired value) and

Process Variable (actual value). The PID

output deviation signal [OD] (output

terminal function option code 04)

indicates when the error magnitude has

exceeded a magnitude you define.

Motor current

Overload

signal

C41

t

t

0

1

0

Output

frequency

Arrival

signal

C43

C42

t

t

0

1

0

PID Error (PV–SP) deviation threshold

Devia-

tion sig-

C44

t

t

SP

Output

PV

0

1

0

“C” Function

Run

Mode

Edit

Defaults

Func.

Code

Name /

SRW Display

Description

–FE

(CE)

–FU

(UL)

–FR

(Jpn)

Units

C_41 Overload level setting Sets the overload signal level

between 0% and 200% (from 0

to two times the rated current

of the inverter)

✘ Rated current for each

inverter

—

OV Load 03.00A

C_42 Frequency arrival

setting for acceleration

Sets the frequency arrival

setting threshold for the output

frequency during acceleration

✘ 0.0 0.0 0.0 Hz

ARV ACC 000.0Hz