Using Intelligent Input Terminals

Operations

and Monitoring

4–10

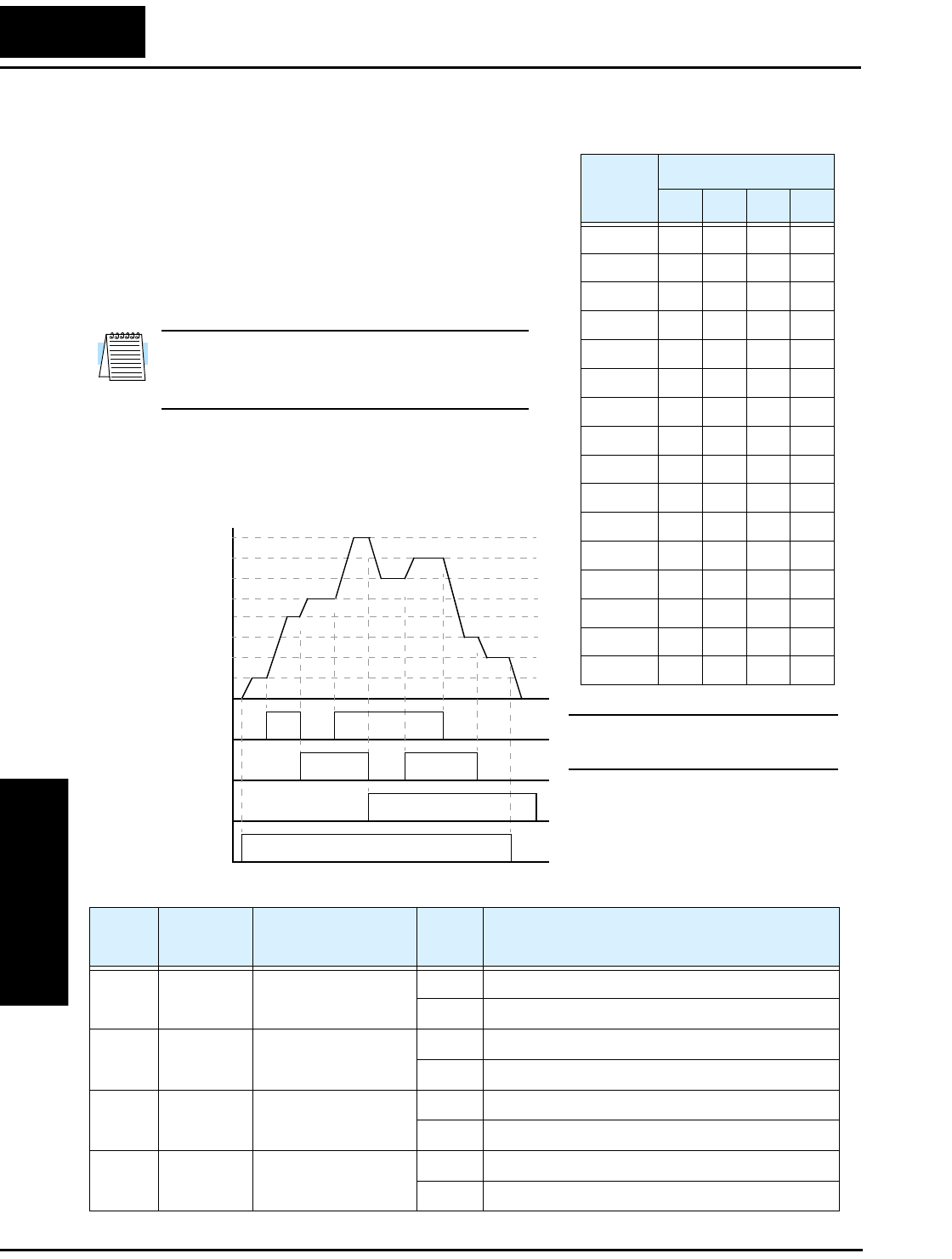

Multi-Speed Select

The inverter can store up to 16 different target

frequencies (speeds) that the motor output uses for

steady-state run condition. These speeds are acces-

sible through programming four of the intelligent

terminals as binary-encoded inputs CF1 to CF4 per

the table to the right. These can be any of the five

inputs, and in any order. You can use fewer inputs

if you need eight or fewer speeds.

Note: When choosing a subset of speeds to use,

always start at the top of the table, and with the

least-significant bit: CF1, CF2, etc.

The example with eight speeds in the figure below

shows how input switches configured for CF1–

CF3 functions can change the motor speed in real

time.

NOTE: Speed 0 is set by the A_20

parameter value.

Multi-

speed

Input Function

CF4 CF3 CF2 CF1

Speed 0 0000

Speed 1 0001

Speed 2 0010

Speed 3 0011

Speed 4 0100

Speed 5 0101

Speed 6 0110

Speed 7 0111

Speed 8 1000

Speed 9 1001

Speed 101010

Speed 111011

Speed 121100

Speed 131101

Speed 141110

Speed 151111

[CF1]

[CF2]

[CF3]

[FWD]

t

Speed

0th

4th

6th

1st

2nd

5th

7th

3rd

1

0

1

0

1

0

1

0

Option

Code

Terminal

Symbol

Function Name

Input

State

Description

02 CF1 Multi-speed Select,

Bit 0 (LSB)

ON Binary encoded speed select, Bit 0, logical 1

OFF Binary encoded speed select, Bit 0, logical 0

03 CF2 Multi-speed Select,

Bit 1

ON Binary encoded speed select, Bit 1, logical 1

OFF Binary encoded speed select, Bit 1, logical 0

04 CF3 Multi-speed Select,

Bit 2

ON Binary encoded speed select, Bit 2, logical 1

OFF Binary encoded speed select, Bit 2, logical 0

05 CF4 Multi-speed Select,

Bit 3 (MSB)

ON Binary encoded speed select, Bit 3, logical 1

OFF Binary encoded speed select, Bit 3, logical 0