L100 Inverter

Configuring

Drive Parameters

3–15

DC Braking Settings

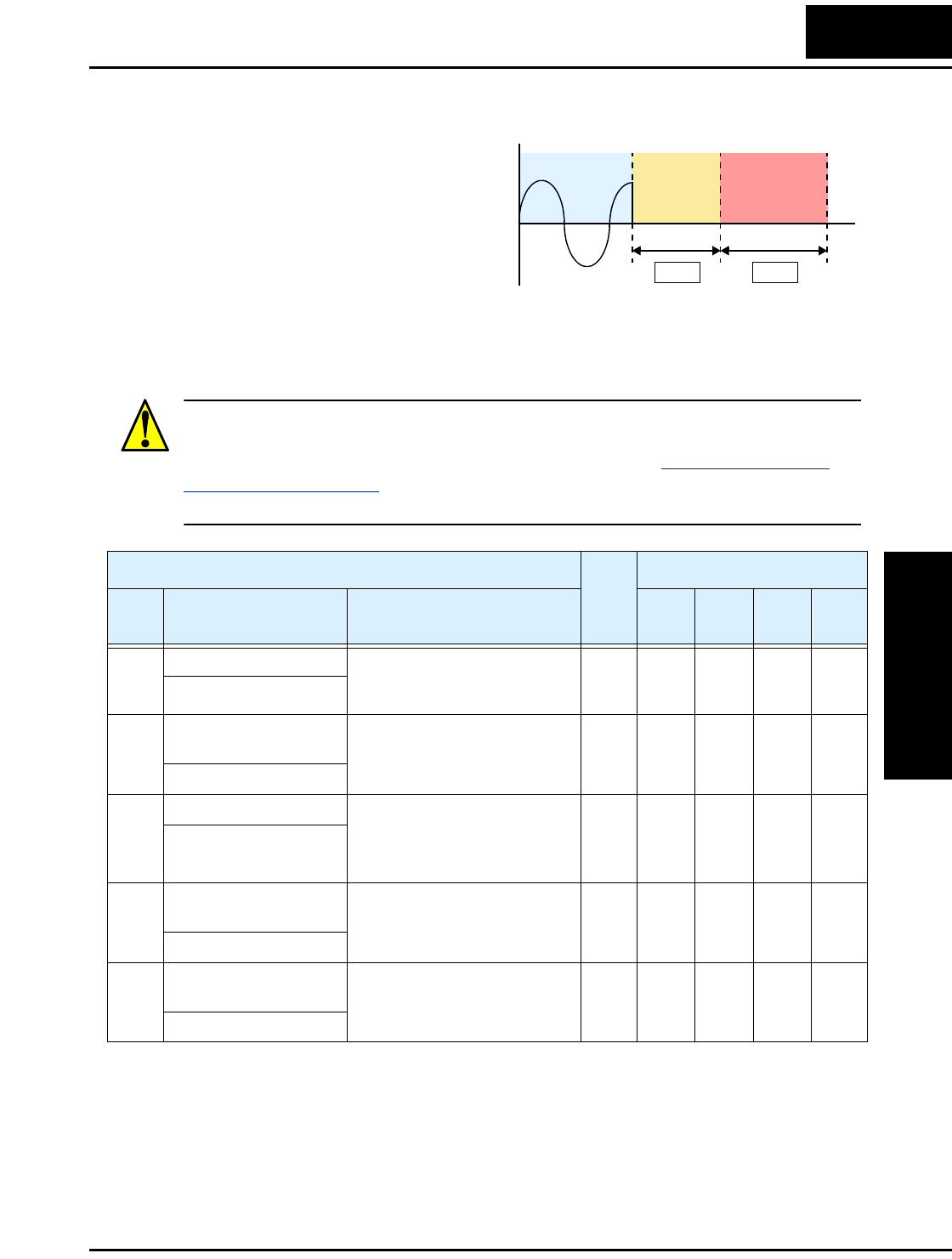

The DC braking feature can provide

additional stopping torque when

compared to a normal deceleration to a

stop. DC braking is particularly useful

at low speeds when normal decelera-

tion torque is minimal. When you

enable DC braking, the inverter injects

a DC voltage into the motor windings

during deceleration below a frequency you can specify (A_52). The braking power

(A_54) and duration (A_55) can both be set. You can optionally specify a wait time

before DC braking (A_53), during which the motor will free run (coast).

CAUTION: Be careful to avoid specifying a braking time that is long enough to cause

motor overheating. If you use DC braking, we recommend using a motor with a built-in

thermistor, and wiring it to the inverter’s thermistor input (see “

Thermistor Thermal

Protection” on page 4–20). Also refer to the motor manufacturer’s specifications for

duty-cycle recommendations during DC braking.

DC brakingFree runRunning

A53 A55

t

0

+

–

“A” Function

Run

Mode

Edit

Defaults

Func.

Code

Name /

SRW Display

Description

–FE

(CE)

–FU

(UL)

–FR

(Jpn)

Units

A_51 DC braking enable Two options; select codes:

00 ...Disable

01 ...Enable

✘ 00 00 00 —

DCB SW OFF

A_52 DC braking frequency

setting

The frequency at which DC

braking occurs,

range is 0.5 to 10 Hz

✘ 0.5 0.5 0.5 Hz

DCB F 00.5Hz

A_53 DC braking wait time The delay from the end of Run

command to start of DC

braking (motor free runs until

DC braking begins)

✘ 0.0 0.0 0.0 sec.

DCB WAIT 0.0s

A_54 DC braking during

deceleration

Applied level of DC braking

force, settable from 0 to 100%

✘ 000%

DCB V 000

A_55 DC braking time for

deceleration

Sets the duration for DC

braking, range is 0.1 to 60.0

seconds

✘ 0.0 0.0 0.0 sec.

DCB T 00.0s