L100 Inverter

Operations

and Monitoring

4–11

While using the multi-speed capability, you can monitor the current frequency with

monitor function D_01 during each segment of a multi-speed operation.

There are two ways to program the speeds into the registers A_20 to A_35:

1. Standard keypad programming:

a. Select each parameter A_20 to A_35.

b. Press the key to view the parameter value.

c. Use the and keys to edit the value.

d. Use the key to save the data to memory.

2. Programming using the CF switches. Set the speed by following these steps:

a. Turn the Run command OFF (Stop Mode).

b. Turn each switch ON and set it to Multi-speed. Display the value of F_01 on the

digital operator.

c. Set the desired output frequency by pressing the and keys.

d. Press the key once to store the set frequency. When this occurs, F_01

indicates the output frequency of Multi-speed n.

e. Press the key once to confirm that the indication is the same as the set

frequency.

f. Repeat operations in 2. a) to 2. e) to set the frequency of other Multi-speeds. It

can be set also by parameters A_20 to A_35 in the first procedure 1. a) to 1. d).

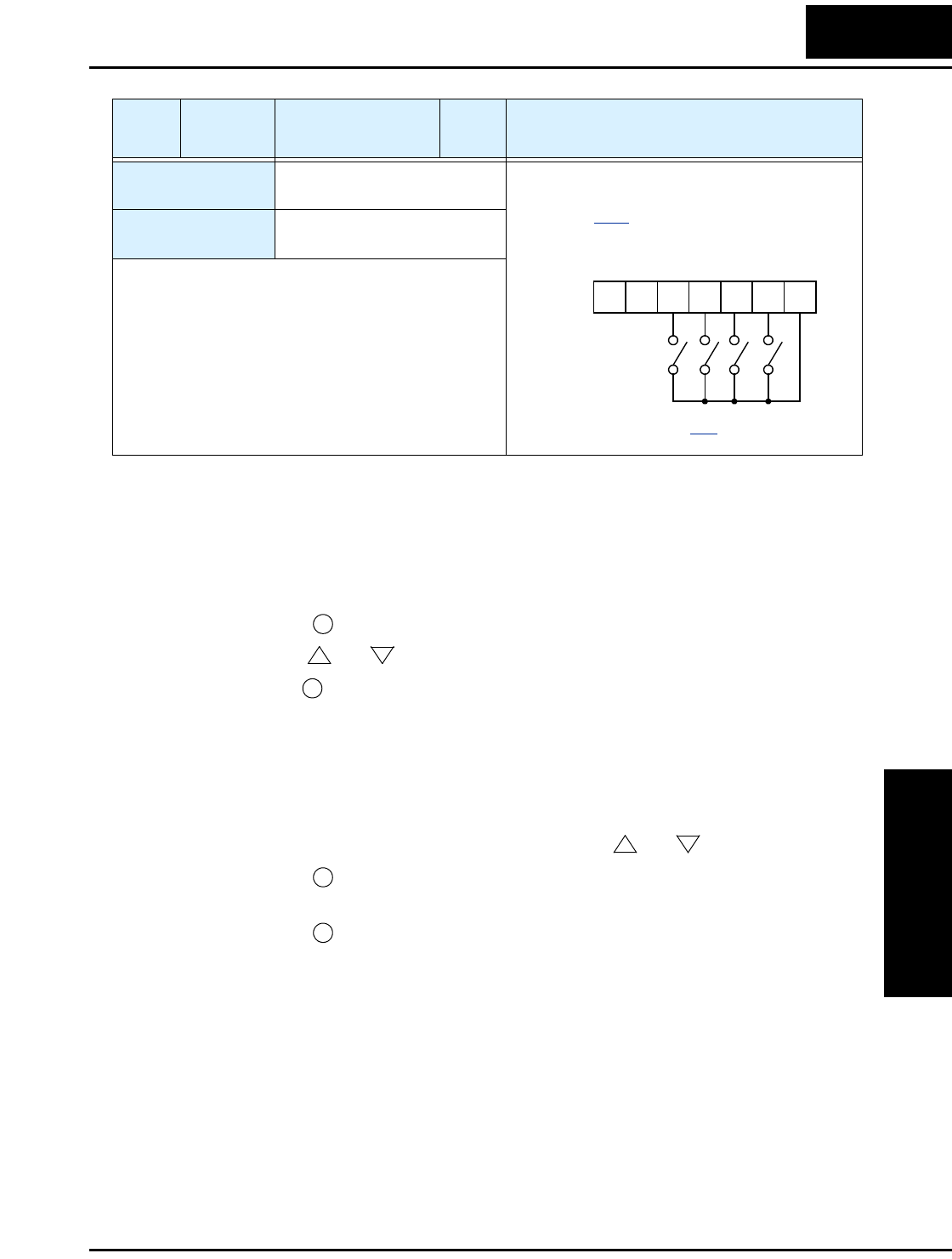

Valid for inputs:

C_01, C_02, C_03, C_04,

C_05

Required settings: F_01, A_01 = 02,

A_20 to A_35

Notes:

•

When programming the multi-speed settings, be

sure to press the Store key each time and then set

the next multi-speed setting. Note that when the

key is not pressed, no data will be set.

• When a multi-speed setting more than 50Hz(60Hz)

is to be set, it is necessary to program the maximum

frequency A_04 high enough to allow that speed.

Option

Code

Terminal

Symbol

Function Name

Input

State

Description

Example (some CF inputs require input

configuration; some are default inputs—

see page 3–32

):

See I/O specs on page 4–6.

12345L

P24

CF2

CF3

CF4

CF1

(LSB)(MSB)

FUNC.

1

2

STR

1

2

STR

FUNC.