L100 Inverter

Inverter Mounting

and Installation

2–27

Powerup Test Observations and Summary

Step 10: Reading this section will help you make some useful observations when first

running the motor.

Error Codes - If the inverter displays an error code (format is “E x x”), see “

Monitoring

Trip Events, History, & Conditions” on page 6–5 to interpret and clear the error.

Acceleration and Deceleration - The L100 inverter has programmable acceleration and

deceleration values. The test procedure left these at the default value, 10 seconds. You

can observe this by setting the potentiometer at about half speed before running the

motor. Then press RUN, and the motor will take 5 seconds to reach a steady speed. Press

the STOP key to see a 5 second deceleration to a stop.

State of Inverter at Stop - If you adjust the motor’s speed to zero, the motor will slow to

a near stop, and the inverter turns the outputs OFF. The high-performance L100 can

rotate at a very slow speed with high torque output, but not zero (must use servo systems

with position feedback for that feature). This characteristic means you must use a

mechanical brake for some applications.

Interpreting the Display - First, refer to the output frequency display readout. The

maximum frequency setting (parameter A_04) defaults to 50 Hz or 60 Hz (Europe and

United States, respectively) for your application.

Example: Suppose a 4-pole motor is rated for 60 Hz operation, so the inverter is config-

ured to output 60 Hz at full scale. Use the following formula to calculate the RPM.

The theoretical speed for the motor is 1800 RPM (speed of torque vector rotation).

However, the motor cannot generate torque unless its shaft turns at a slightly different

speed. This difference is called slip. So it’s common to see a rated speed of approxi-

mately 1750 RPM on a 60 Hz, 4-pole motor. Using a tachometer to measure shaft speed,

you can see the difference between the inverter output frequency and the actual motor

speed. The slip increases slightly as the motor’s load increases. This is why the inverter

output value is called “frequency,” since it is not exactly equal to motor speed. You can

program the inverter to display output frequency in units more directly related to the load

speed by entering a constant (discussed more in depth on page 3–29

).

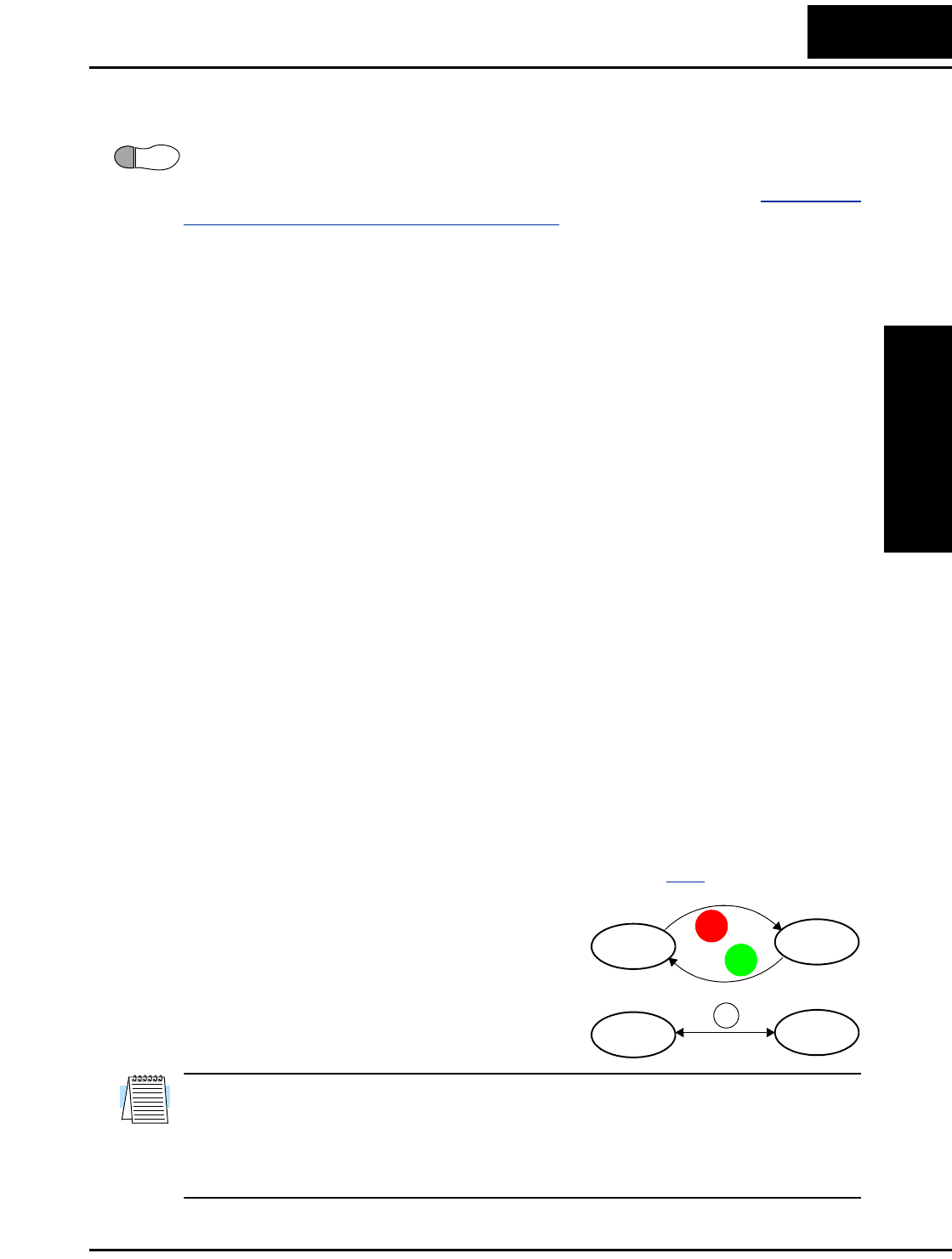

Run/Stop Versus Monitor/Program Modes – The

Run LED on the inverter is ON in Run Mode, and

OFF in Stop Mode. The Program LED is ON when

the inverter is in Program Mode, and OFF for

Monitor Mode. All four mode combinations are

possible. The diagram to the right depicts the modes

and the mode transitions via keypad.

NOTE: Some factory automation devices such as PLCs have alternate Run/Program

modes; the device is in either one mode or the other. In the Hitachi inverter, however,

Run Mode alternates with Stop Mode, and Program Mode alternates with Monitor

Mode. This arrangement lets you program some values while the inverter is operating—

providing flexibility for maintenance personnel.

10

Speed in RPM

Frequency 60×

Pairs of poles

----------------------------------------

Frequency 120×

# of poles

-------------------------------------------

60 120×

4

--------------------- 1800RPM== ==

Run

Stop

Monitor Program

RUN

STOP

RESET

FUNC.