Choosing a Programming Device

Configuring

Drive Parameters

3–2

Choosing a Programming Device

Introduction

Hitachi variable frequency drives (inverters) use the latest electronics technology for

getting the right AC waveform to the motor at the right time. The benefits are many,

including energy savings and higher machine output or productivity. The flexibility

required to handle a broad range of applications has required ever more configurable

options and parameters—inverters are now a complex industrial automation component.

And this can make a product seem difficult to use, but the goal of this chapter is to make

this easier for you.

As the powerup test in Chapter 2 demonstrated, you do not have to program very many

parameters to run the motor. In fact, most applications would benefit only from program-

ming just a few, specific parameters. This chapter will explain the purpose of each set of

parameters, and help you choose the ones that are important to your application.

If you are developing a new application for the inverter and a motor, finding the right

parameters to change is mostly an exercise in optimization. Therefore, it is okay to begin

running the motor with a loosely tuned system. By making specific, individual changes

and observing their effects, you can achieve a finely tuned system.

Introduction to Inverter Programming

The front panel keypad is the first and best way to get to know the inverter’s capabilities.

Every function or programmable parameter is accessible from the keypad. The other

devices simply imitate the keypad’s layout and inverter access, while adding another

valuable aspect to the system. For example, the Copy Unit can transfer one inverter’s

parameter settings to another inverter, while still providing standard operator keypad

control. In this way, you can use a variety of programming devices with basically the

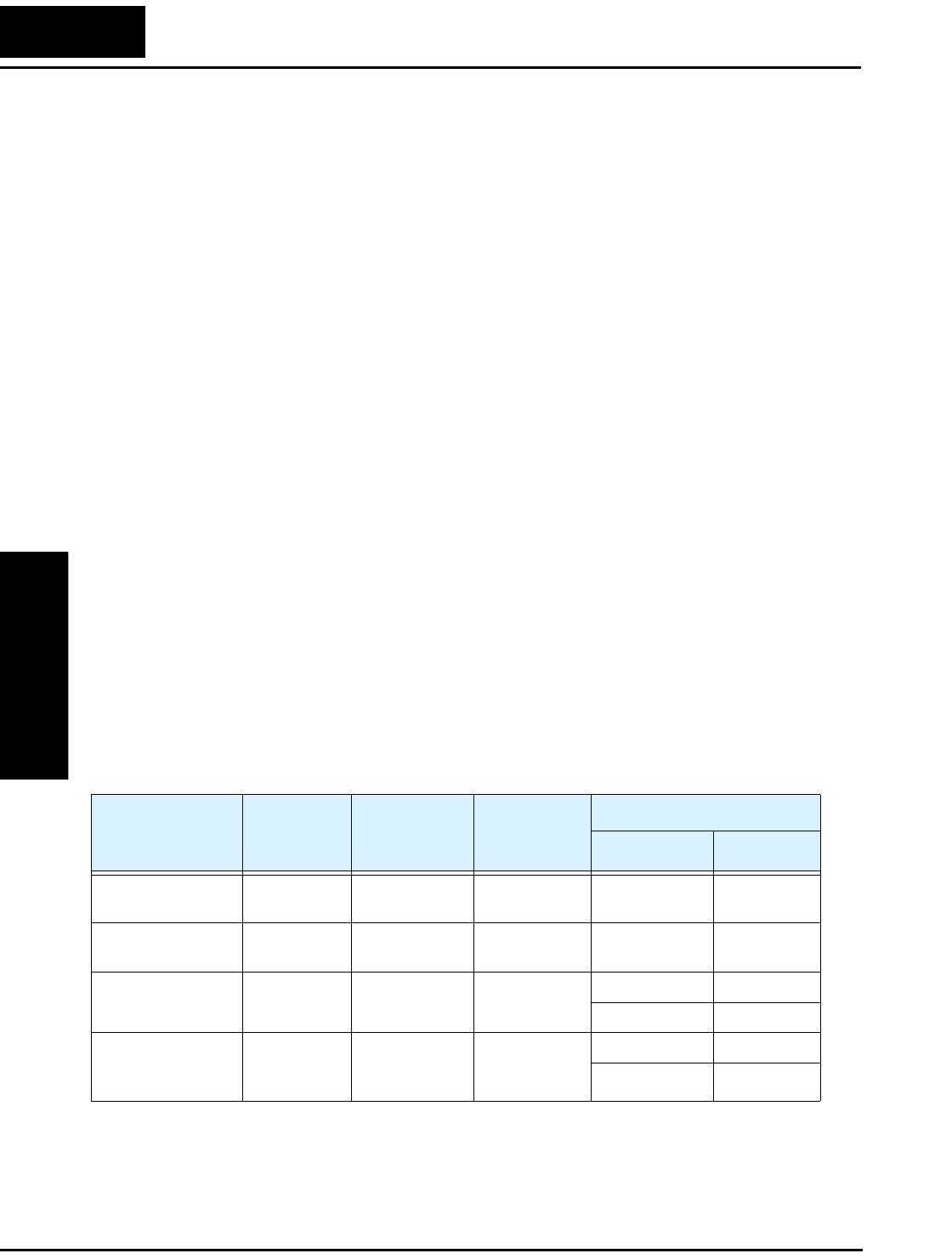

same keypad skills. The following table shows various programming options, the

features unique to each device, and the cables required.

Device

Part

Number

Parameter

Access

Parameter

setting

storage

Cables (choose one)

Part number Length

Inverter keypad — Monitor and

program

EEPROM in

inverter

——

DOP Professional

Software (for PC)

DOP–PRO Monitor and

program

PC hard drive

or diskette

(Included with

software)

2 meters

Digital Operator/

Copy Unit

SRW–0EX Monitor and

program

EEPROM in

operator panel

ICS–1 1 meter

ICS–3 3 meters

Operator Monitor OPE–J Monitor only none on

operator

monitor

ICJ–1L 1 meter

ICJ–3L 3 meters