Front

-

+

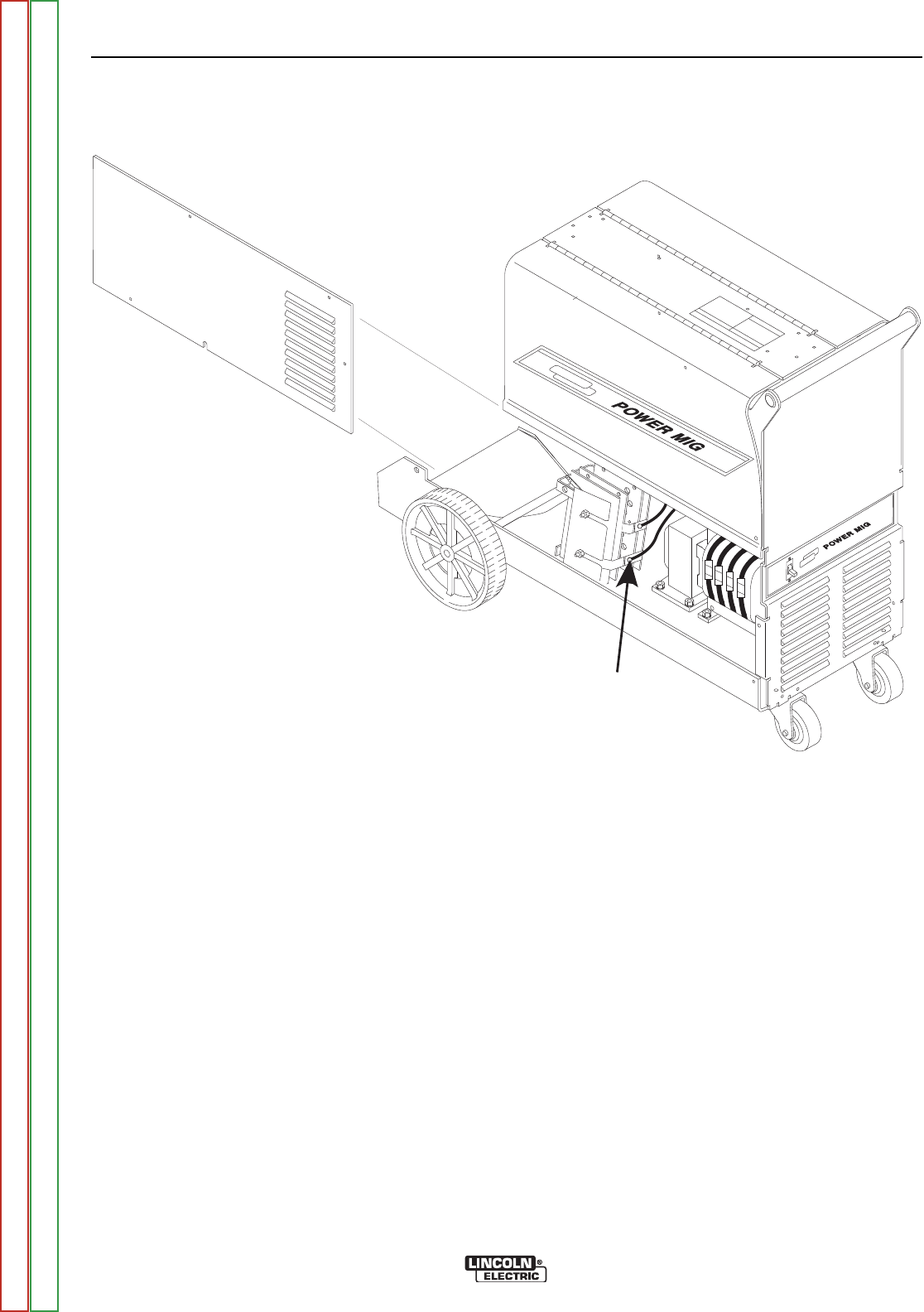

Negative Lead

FIGURE F.6 – RECTIFIER TEST POINTS

OUTPUT BRIDGE RECTIFIER TEST (continued)

PROCEDURE

1. Remove input power to the Power MIG® 215XT

machine.

2. Using the 3/8” nutdriver, remove the left case

side.

3. Locate and disconnect the negative lead from

the output rectifier bridge assembly. Be sure

there is no electrical contact between the recti-

fier and the lead. See Figure F.6.

NOTE: Do not disassemble the rectifier assembly.

4. Test for “shorted” or “leaky” diodes by checking

from the anodes to the cathodes of the diode

heatsink plates. The readings should be high

resistance in one polarity and low resistance in

the opposite polarity.

5. If any of the diodes are “leaky” or “shorted” the

output rectifier assembly should be replaced.

6. When the test is complete, replace the negative

output lead previously removed.

7. Replace the left case side.

TROUBLESHOOTING AND REPAIR

F-20 F-20

Power MIG® 215XT

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC