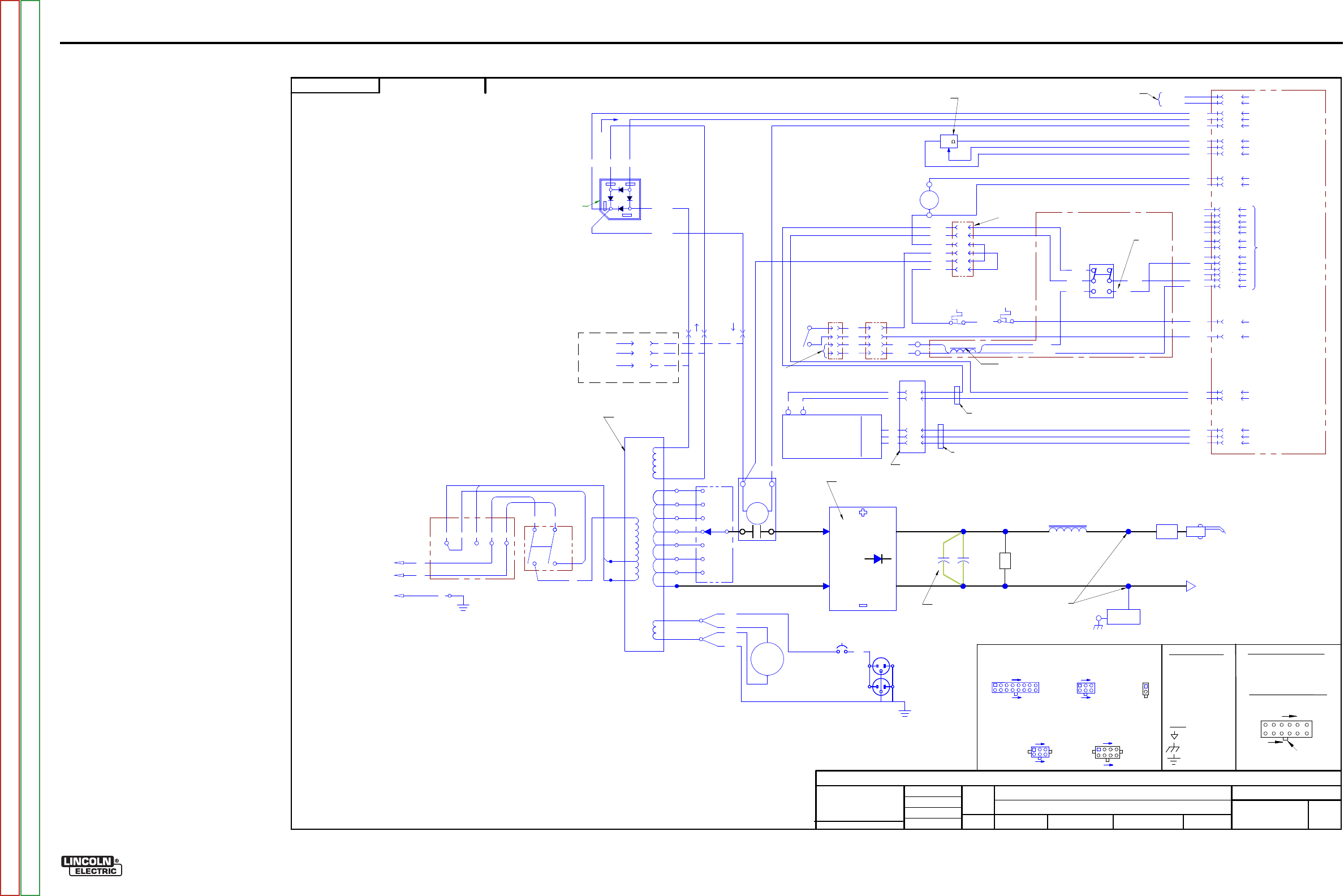

ElEcTrical DiaGramS

G-3

pOWEr miG® 215XT

SchEmaTic - cOmplETE machiNE - l12308-1 pG1

J1

,

J1

4

CAVITY

NUM

BERI

NG

SEQ

UE

N

CE

(

COMPONENT S

IDE OF P.C. BOARD

)

J2

J3

9

PA

J4

(

T

RI

GG

ER

,

T

ACH

OMET

ER

,

MOT

OR

S

IDE)

8

16

1

4

6

1

3

8

1

4

5

1

2

4

6

1

3

(

NO

N

-LEAD SIDE OF

CO

N

NECTOR

)

LE

A

D

COLO

R

CO

DE:

B-BL

ACK

G-GRE

EN

O-ORA

NG

E

R-RE

D

U-BLU

E

W-

W

HIT

E

Y-Y

ELLO

W

COM

P

ON

E

NT

V

AL

UE

U

NIT

S:

CAPA

CITO

R:

MFD/

V

OLTS

RESI

STO

R: O

HM

S/W

ATTS

CO

NNE

CTOR

P

IN N

UM

BERS:

VIEW O

F

CONNECTOR ON PC BOARD

1

2

6

712

LATC

H

EX

.

1

2

PIN CONNECTOR

LABELS:

COMM

ON

FRAM

E

G

RO

UND

EA

RTH

GROU

ND

L12308-1

POWER MIG

216

MACHIN

E

SCHEM

ATI

C

NO

NE

L12308

DO N

OT S

CA

LE

TH

IS

D

RAW

ING

EQU

IP

ME

NT

TYPE

:

SU

BJ

EC

T:

UF

CRM41

566

1

PA

GE

___

OF

___

2

ENGINE

ERING CONTROL

L

ED

MANUFACTURER:

No

T

HIS

DOC

UME

N

T C

ON

TAINS P

R

OP

RIETA

RY IN

FO

RMATIO

N

OW

NE

D BY L

IN

C

OLN

GLOBAL, IN

C. A

N

D MAY NOT BE

D

UPLI

CA

TE

D,

C

OMMU

NI

CA

TE

D

TO OT

HE

R PA

R

TIES O

R

USE

D

FO

R A

NY P

U

RP

OSE WIT

HOU

T THE E

X

PRESS

W

RITTE

N PE

RMISSIO

N

OF LIN

C

OLN

GLOBAL, IN

C.

PROPR

IE

T

AR

Y &

CO

N

FI

DE

NTIAL:

REVISED

PA

GE

2.

t

MAT

ERIAL TOLERANCE (

"

")

TO A

G

REE

WITH PUBLISHED

STANDARDS.

O

N ALL AN

GLES IS

±

.5

OF A

DEG

REE

ON

3

P

LA

C

E

DECIM

ALS

IS

±

.0

02

i

n.

(

±

0.05

mm)

O

N 2

PLACE DEC

IMALS IS

±

.02

in

. (

±

0.5

mm)

U

NLESS

OTHERW

ISE

SPE

C

IF

IE

D

TOLERA

N

CE

:

MANUFACTURIN

G

TOLERANCE PER

E2056

C

HA

N

GE DE

T

AIL:

REFE

RE

N

CE:

SCA

LE:

MATE

RIAL

DISPO

SITION:

APP

ROV

AL

DAT

E:

PRO

JE

CT

NU

MBE

R:

DOCUMENT

N

UMBER:

DOCUMENT

REVIS

I

ON:

U

NITS:

IF

PRIN

TED

@

A2

S

IZE

IN

CH

4/9/

2010

cstuble

T. S

PEAR

OBS

DR

A

WN

BY:

E

NG

IN

EE

R:

CLEVELAND

APP

RO

VE

D:

CO

NT

ROL:

C

L12308-1

1

1104B

G

F

E

D

C

B

A

X10

X9

CONTACTOR

(NOR

MALLY

OPEN)

FAN

MO

TOR

X5

X7

X8

27.8V

X6

S

IN

GLE

PHASE

B

RI

DG

E

RE

CTIFIE

R

4

3

2

T

RI

GG

ER

G

UN

R2

10K

POT

X1

TRANSFO

RME

R

MAIN

H2

X3

X2

H1

22

0

H1

H4

SUPPLY

L

INE

TO

S

INGLE PHASE

L1 L2

L1

X4

H2

G

PANEL

RECO

NNE

CT

S1

SWI

TCH

LINE

H1

20

8V

L2

B

H3

WO

RK

TO

H3 H4

324

325

W

CODE

NATIONAL

ELECTR

ICAL

TO

GROUN

D PER

1107

A

1104A

TAP

SELEC

TOR S

WI

TCH

23

0

V

X11

115V

X12

CIR

CUIT

BREAKER

15A

X12

403

115V

401A

2J6

R.

F. FI

L

TE

R

12J1

8J1

1112A

1108A

CONTROL

P.C.

B

OARD

(SCHEMA

TI

CG441

4)

16J1

1116A

M

OT

O

R -

COM

SOLEN

OI

D

OPE

N = 3

6.5

VDC

5J1

1105A

M

OT

O

R +

1J1

2J1

1101A

1102A

15J1

1115A

5VDC

T

ACH

SUP

PL

Y

T

ACH

SI

GN

AL

T

ACH C

OM

3J4

4J4

5J4

R

U

B

R

U

B

TACHMOTOR / GEARBOX

OHMS=1.5TO6.5

1.8V DC@50IN/M IN

26.5VD C@700IN/MIN

LOCATE D

ONRIGHT

CASEBACK

8J4

7J4

BW

OUTPUT

CHOKE

5

0

w

a

t

t

s

4

0

o

h

m

s

R1

+

31000/50

LOCATE DO NB ASEIN

THEMIDDLEOFTHE

MACHINE

CONTROLSTHE

FUNCTIONALITYOF

THEMACHINE

-

+

RECTIFIER

DIODE

BRIDGE

LOCATEDON

TRANSFORMER

BAFFLE

LOCATEDO NF RONT

OFMACHINE'SBASE

11

06A

11

06B

X9

11

14A

X10

12.0

VAC

14.1

VAC

16.4

VAC

18.7

VAC

20.9

VAC

23.2

VAC

25.6

VAC

LOCATEDO N

MACHINE'SBASE

P.C.BOARD

COMPARTMENTSIDE

LOCATEDINSIDE

OFP.C. BOARD

COMPARTMENT

0VN

O

TR

IG

GER

8.6

V

T

R

IG

GER

LOCATE DO N

CASEBACK

401

402

402A

T

AP

G

= 3

6.0

VDC

T

AP

F

=

32.8

VDC

T

AP

E

= 2

9.6

VDC

T

AP D

=

26.5

VDC

T

AP C

=

23.2

VDC

T

AP

B

= 2

0.0

VDC

T

AP

A

= 1

6.9

VDC

LOCATEDO NMACHINE'S

BASE, TOWARDSBACK,

WIREDRIVESIDE

BANKO FTWO

CAPACITORS

14J1

1114A

COM

6J1

1106A

+3

9.2

5VDC

7J1

1107A

CO

NT

A

CT

OR

B

W

TOROID

(1

TURN)

TOROID

(1

TURN)

4J6

11J1

1111A

4J1

LOCATEDO N

MAIN

TRANSFORM ER

WINDINGS

LOCATE DO N

IN PU T

RECTIFIER

12V

20O HMCO IL

6VHOLD

GAS SOLENOID

13J1

1113A

3J1

1103A

9J1

1109A

LOCATEDON

CASEFRONT

ADJUSTSWIRE

FEEDSPEED

LOC ATEDON

BOTTOMSIDEO F

OUTPUTSTUD

LOCATEDINP.C.BOARD

COMPARTMENT

LOCATEDON

CASEBACK

N.C.

N.C.

MOTOR

G

EA

RBOX

LOC ATEDON

MACHINE'S

LEFTREA R

LOC ATEDON

CASEBACK

WITHREAR

TOFRONT

AIRFLOW

LOCATEDO N

MACHINE'SFRONT

LEFTMIDW AY

F

AN I

S C

ON

T

INUO

USL

Y

ON

WHE

N P

O

WER

SW

IT

CH IS

ON

MO

VED

T

O C

ON

T

RO

L

BO

ARD

ON C

OD

E 1

109

9

AND HI

GH

ER

+

-

+

LOC ATEDONBASEO F

FEEDERCO MPARTMENT

MOLD

ED

OUT

P

UT

STU

DS

40

VDC

14J1

10J1

CONTROL

BOARD

POWER

ON C

OD

E 1

109

9 AND

HI

GH

ER

FRONTOF DRIVE

ROLLAREA

LOCATEDINSIDE OF

P.C. BOARDCOMPARTMENT

FRON TLEFT

RATED@300A

OHMS=10

LOCATEDINSIDE

OFP.C. BOARD

COMPARTMENT

B

T

O R

=

5

T

O

6V

@ A

NY S

PE

ED

B

T

O U

=

3.5

V @

ANY

SP

EED

1105A

1116B

1105B

1104C

1106C

1104D

6J5

3J5

1J5

5J5

4J5

2J5

MOTORUSE

SOLENOID/SPOOL

GUNDETECTUSE

GUNTRIGGER

USE

SPOOLGUN

DETECTSIGNAL

LOCATE DINSIDE

OFP.C. BOARD

COMPARTMENT

LOC ATEDINS IDEO FP .C.

BOARDCOMPARTMENT

14J1

10J1

FR

O

M

X

10

FR

O

M

X9

RIGHTREAR

NEARFAN

FRONT

TOP

LEFT

(T O PL E FTF R O N TO FWE LDER)

1J2

4J2

2J3

1J3

6J2

2J2

3J2

FORADDITIONAL

SPOOLGUNOPTIONS/

ADAPTERPANEL

CONNECTIONS

(SEEPAGE2)

1124

1117A

1123

5J2

1J6

3J6

1118

1117

TOROID

(1

TURN)

1117A

1118A

1118A

1123

1124

1122

1121

LOCATE DIN

MAGNUM100SG

READYADAPTER

PANELNEXT TO

WIREDRIVE.

SWITCH SHOWN IN MAGNUM

100 PUSH GUN POSITION

326

327

SHOWSMAGNUM

PUSHGUN

INSTALLED

MAGNUM 100SG ADAPTER PANEL

6J14

16J14

12J14

2J14

14J14

6J1

100 SG

SPOOL GUN

DETECT

+

100 SG SPOOL

GUN MOTOR

USE

ONLYON

EARLYCODES

G-3

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Enhanced Diagram