OUTPUT DIODE

BRIDGE

RECTIFIER

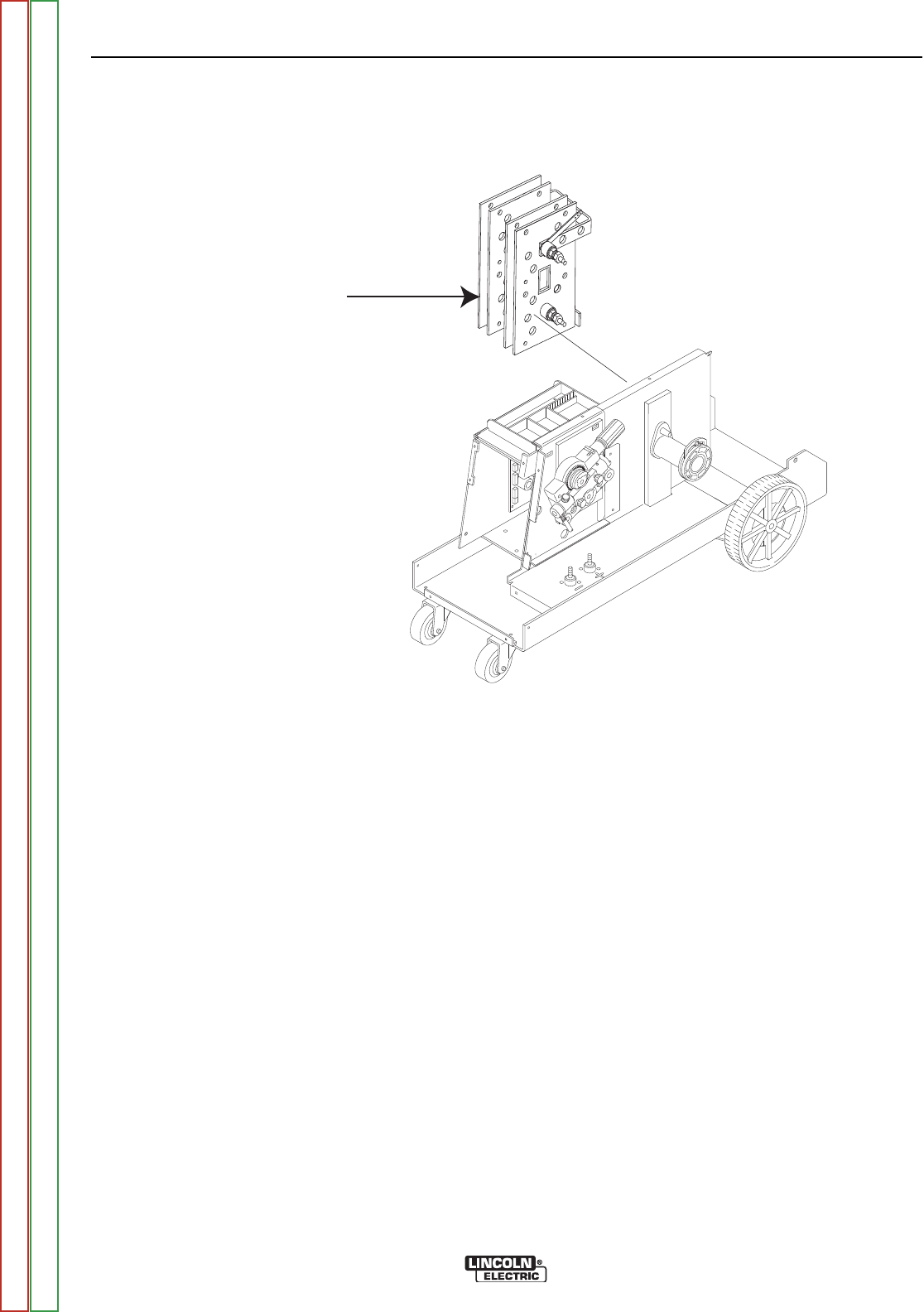

FIGURE F.12 – OUTPUT DIODE BRIDGE RECTIFIER LOCATION

OUTPUT DIODE BRIDGE RECTIFIER

REMOVAL AND REPLACEMENT PROCEDURE (continued)

PROCEDURE

1. Using a 3/8” nutdriver, remove the left side of

the case wraparound cover.

2. Locate the output diode bridge rectifier. See

Figure F.12.

3. Using a 1/2” nutdriver label and remove the four

thick black leads connected to the rectifier.

NOTE: Be sure to label lead terminals also.

Take note of washer placement upon

removal.

4. Label and remove leads 104A and 104B. See

Wiring Diagram.

5. Using a 5/16” nutdriver locate and remove the

four bolts mounting the rectifier bracket to the

bottom of the machine. These bolts can be

accessed easily from the bottom of the

machine. See Figure F.13.

6. Carefully manipulate the output diode bridge

rectifier and the mounting bracket out of the left

side of the machine.

7. Using a 1/2” nutdriver remove the three bolts

mounting the bracket to the rectifier. The recti-

fier is now ready for repair or replacement. See

Figure F.13.

8. Mount the new rectifier to the mounting bracket

using the three 1/2” bolts.

9. Carefully manipulate the rectifier and mounting

bracket as a one back into the machine to its

proper location.

10. Mount the unit to the bottom of the machine

using the four 5/16” mounting bolts previously

removed.

11. Reconnect leads 104A and 104B previously

removed.

12. Reconnect the four thick black leads previous-

ly labeled and removed using a 1/2” nutdriver.

13. Replace the left side of the case wraparound

cover.

TROUBLESHOOTING AND REPAIR

F-34 F-34

Power MIG® 215XT

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC