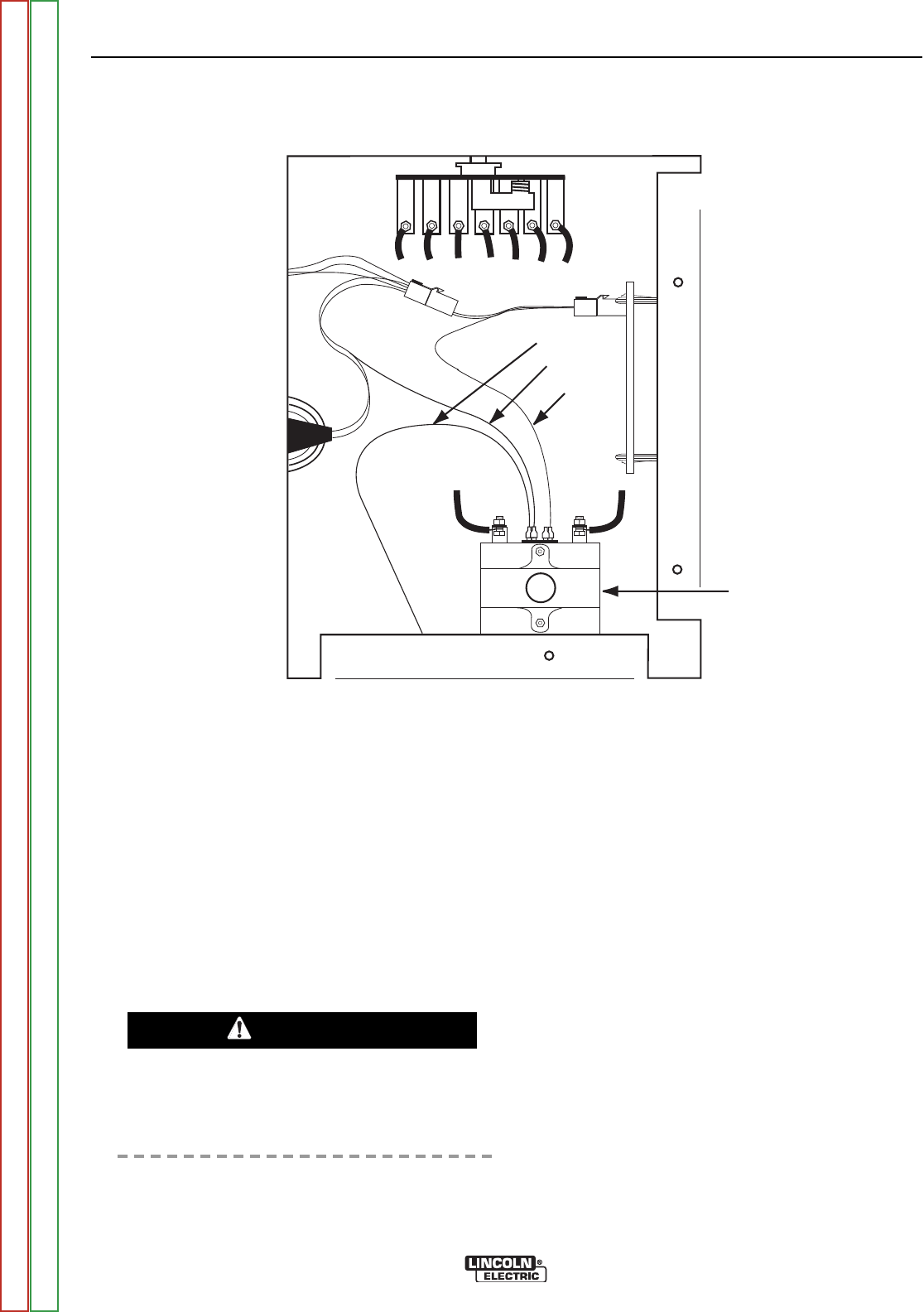

107A

106C

106B

Output

Contactor

FIGURE F.7 – CONTACTOR TERMINALS AND LEADS

CONTACTOR TEST (continued)

TROUBLESHOOTING AND REPAIR

F-22 F-22

Power MIG® 215XT

PROCEDURE

1. Remove the input power to the Power MIG®

215XT machine.

2. Using the 5/16” Nutdriver, remove the tool tray.

3. Locate and remove leads 106B, 106C and 107A

from the contactor coil terminals. See Figure

F.7. See the Wiring Diagram.

4. Using the 7/16” wrench, remove one lead from

the contactors large terminals. See Figure F.7.

See the Wiring Diagram.

5. Carefully apply 12 VDC to the contactor coil

leads. (small terminals)

Do not leave the 12 VDC applied to the contac-

tor coil for a prolonged period of time (15 sec-

onds maximum). Damage to contactor may

result.

6. If the contactor does not activate when the

12VDC is applied, the contactor is faulty.

Replace.

7. If the contactor activates when the 12VDC is

applied, check the resistance between the two

large terminals with the contactor activated. The

resistance should be very low (0 to 1 ohm).

8. If the resistance is “high” or “open” between the

two large terminals when the contactor is acti-

vated, the contactor is faulty. Replace.

9. If the contactor activates and the resistance

between the terminals is low when the 12 VDC

is applied, the contactor is good

NOTE: When the contactor is not activated, the

resistance between the terminals should

be very high (infinite). If the resistance is

always low, the contacts are “stuck” and

the contactor is faulty. Replace.

10. When the test is complete, replace leads 106B,

106C and 107A.

11. Replace the lead previously removed from one

of the contactor large terminals.

12. Replace the tool tray.

CAUTION

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC