POWER FEED 10M SINGLE/DUAL

OPERATION

B-23 B-23

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

200

----

WFS AMPS

V

OLTS TRIM

LESS

D

EPOSITION

MORE

D

EPOSITION

EFFECT / RANGE

PEAK CURRENT

BACKGROUND

CURRENT

TAIL OUT

(STT ll MODES

ONLY)

DESCRIPTION

Peak Current acts similar to an

arc pinch control. Peak Current

sets the arc length and pro-

motes good fusion. Higher

peak current levels will cause

the arc to broaden momentarily

while increasing arc length. If

set too high, globular transfer

may occur. Setting it too low

may cause instability and wire

stubbing. Best practice is to

adjust for minimum spatter and

puddle agitation.

Background Current controls

the overall heat input in the

weld. High background cur-

rents flatten the weld bead, and

low background currents create

a taller rounded contour.

Tail out provides additional

power without the molten

droplet becoming too large.

Increase as necessary to add

heat input without increasing

arc length. Often this results in

faster travel speeds. Note that

as tail out increases, the peak

current and/or background cur-

rent may need to be reduced.

PREFLOW TIME

0 - 10 seconds

RUN-IN WFS:

Off, 50 to150 in/min.

Start Procedure

FUNCTION

Adjusts the time the gas flows

after the trigger is pulled and

prior to feeding wire.

Run-in sets the wire feed speed

from the time the trigger is

pulled until an arc is estab-

lished.

The Start Procedure controls

the WFS. Trim at a specified

time at the beginning of the

weld. During the start time, the

machine will ramp up or down

from the Start Procedure to the

preset Welding Procedure.

START OPTIONS

PARAMETER RANGE

Postflow Time:

0 to 10 seconds

Crater Procedure

Burnback:

0 to .25 Seconds

Spot Timer:

0 to 10 Seconds

FUNCTION

Adjusts the time that shielding gas

flows after the welding output turns

off.

Crater Procedure controls the

WFS and volts for a specified time

at the end of the weld after the trig-

ger is released. During the Crater

time, the machine will ramp up or

down from the Weld Procedure to

the Crater Procedure.

The burnback time is the amount of

time that the weld output continues

after the wire stops feeding. It pre-

vents the wire from sticking in the

puddle and prepares the end of the

wire for the next arc start.

Adjusts the time welding will con-

tinue even if tigger is still pulled.

This option has no effect in 4-Step

Trigger Mode.

END OPTIONS

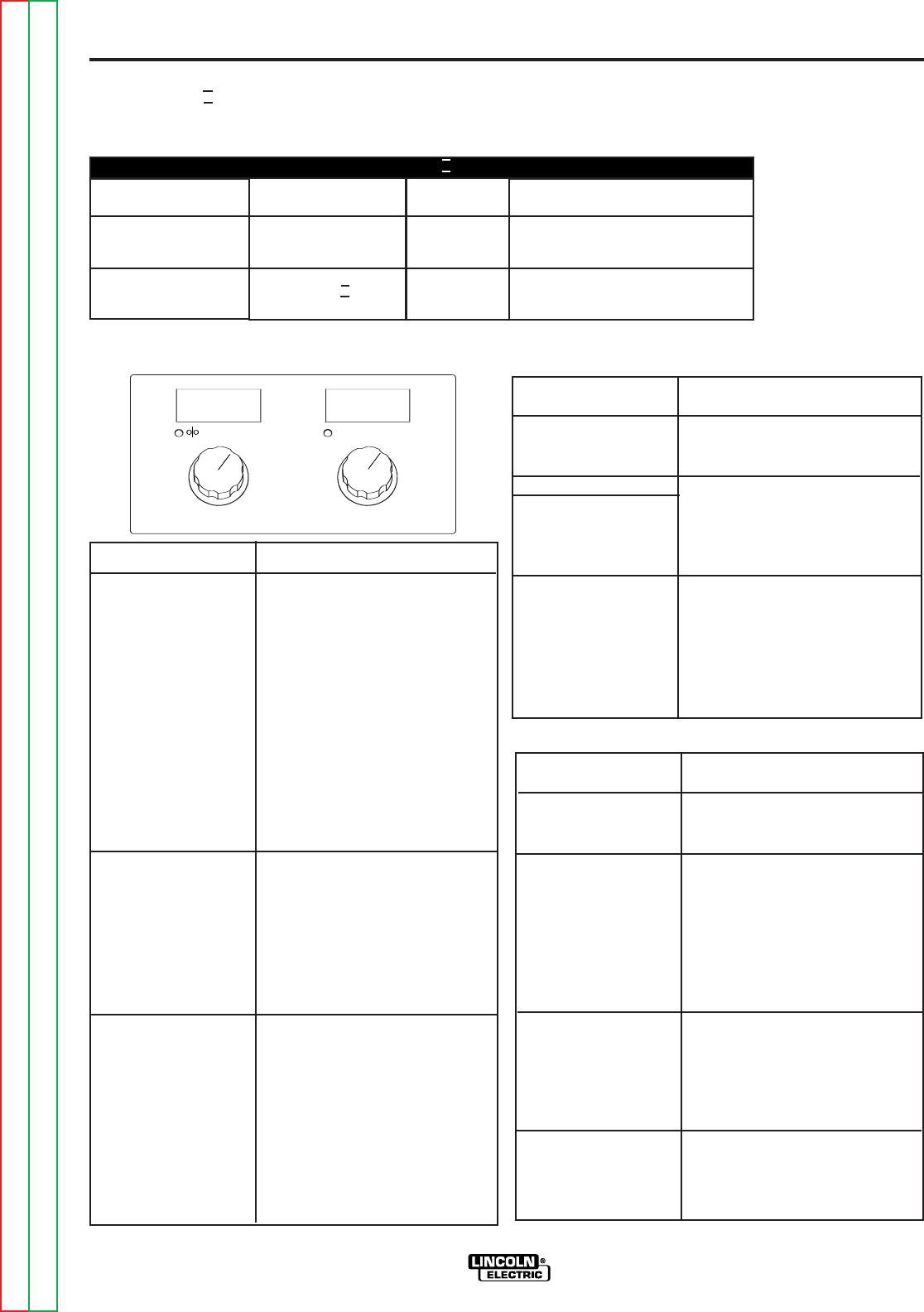

MACHINE FUNCTIONALITY BY WELD PROCESS

STT AND STT II (SYNERGIC)

Use the following tables to review how the machine functions (output controls, arc control, Start options and weld

options) for the weld modes listed in the top table.

OUTPUT CONTROL KNOBS (There is no Voltage control when STT welding.)

MATERIAL

STEEL

STAINLESS

STEEL

ST

AINLESS

GAS

Ar/CO

2

CO

2

Ar/CO

2

CO

2

PROCESS

STT

STT II

WIRE SIZE

0.035 0.045 0.052

109 125 125

110 126 126

STT AND STT II MODES