POWER FEED 10M SINGLE/DUAL

OPERATION

BB-14 BB-14

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Recalling from Memory

To recall the contents of a memory into the active proce-

dure, momentarily push the desired memory button (for

less than 2 seconds). The saved parameters will be

copied into the active procedure, and the LED of the

memory button will light indicating the source of the infor-

mation. As with saving to memory, this light will remain lit

as long as the contents of the source memory remain

equal to the contents of the associated procedure.

If a constant current mode is saved to memory with the

power source in the "on" state, the "on" status will be

changed to "off" when the procedure is recalled. This pre-

vents a potential safety hazard if a memory button is

pushed and the power source unexpectedly turns on.

2 STEP / 4 STEP OPERATION

The Wire Drive has a 2 Step / 4 Step switch located

near the gun connector. 2-Step Trigger Mode operation

requires the operator hold the gun trigger closed in

order to weld. 4-Step Trigger Mode eliminates the need

to hold the gun trigger closed while welding. User-

selectable 4-step modes with or without current inter-

lock. The switch in the down position will enable 2-Step

operation and in the up position enables 4 -Step oper-

ation. This switch has no effect in CC modes of opera-

tion, such as stick welding. Both 2 and 4 -Step can be

operated in Synergic and Non-Synergic modes. In a

Synergic mode, machine output tracks Wire Feed

Speed (WFS) during welding. In Non-Synergic modes,

machine output is independent of WFS.

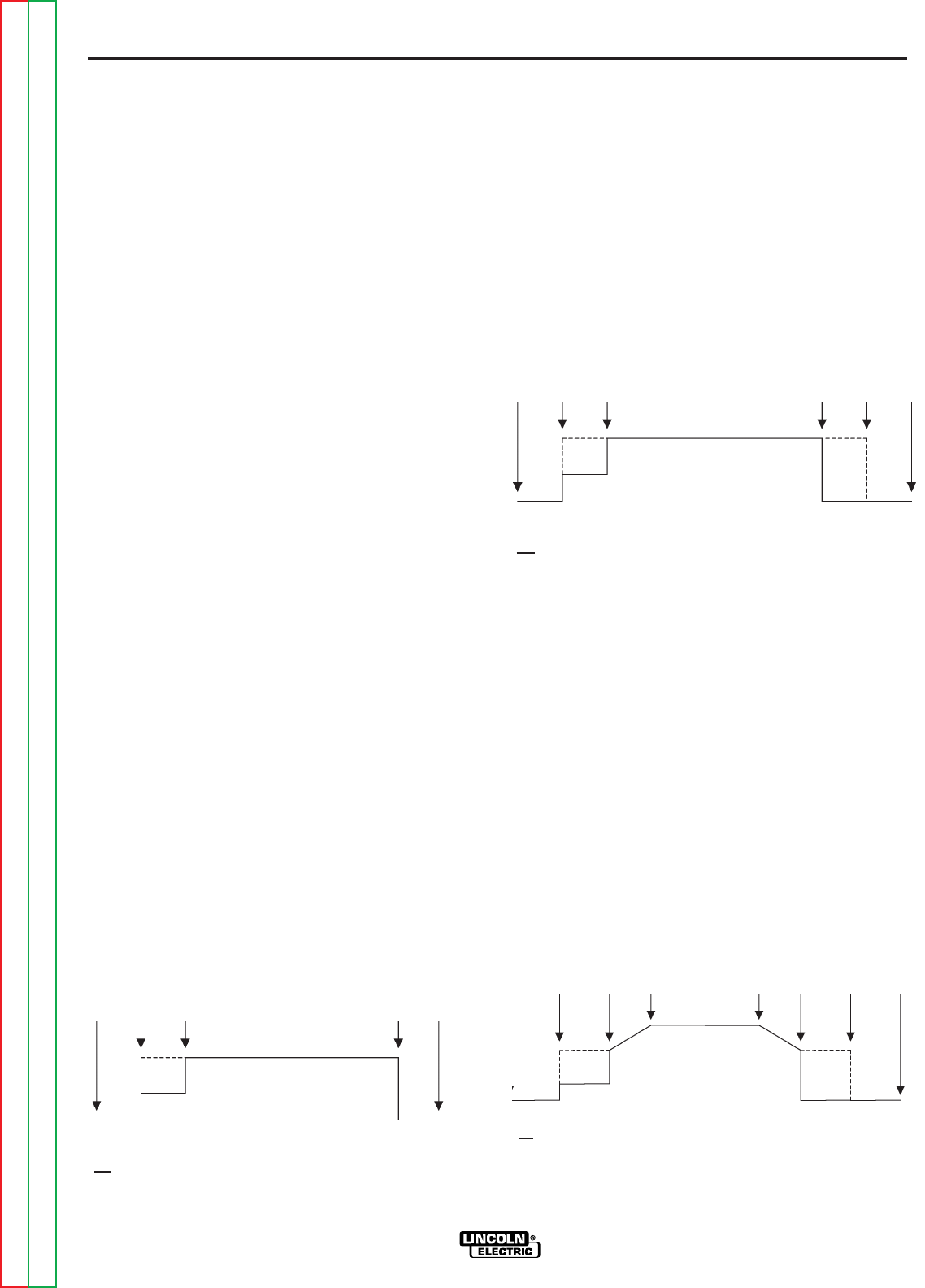

2 Step Synergic Operation:

Without Start/Crater/Burnback functions active

Waveform Sequence:

1. Trigger is pulled; Preflow sequence begins and runs

until preflow timer expires.

2. Strike sequence initiates until Arc is established.

3.

Arc established; Weld sequence begins.

4. Trigger released (Arc extinguished); Postflow

sequence begins and runs until postflow timer

expires.

5. End of sequence.

WFS vs. Work point Waveform

= solid line represents WFS

---=

dashed line represents Work point or Machine Output

2 Step Synergic Operation:

With Burnback function active.

Waveform Sequence:

1. Trigger is pulled; Preflow sequence begins and

runs until preflow timer expires.

2. Run-In sequence initiates until Arc is established.

3. Arc established; W

eld sequence begins.

4. Trigger released (Arc extinguished); Burnback

sequence begins and runs until burnback timer

expires.

5. Postflow sequence begins and runs until postflow

timer expires.

6. End of sequence.

WFS vs. Work point (Output) Waveform

1 2 34 5

1 2 3 4 5 6

= solid line represents WFS

---=

dashed line represents Work point or Machine Output

2 Step Synergic Operation:

With Start/Crater/Burnback functions active.

Waveform Sequence:

1. Trigger is pulled; Preflow sequence begins and

runs until preflow timer expires.

2. Run-In sequence initiates until Arc is established.

3. Arc established; Start sequence begins and runs

for the amount of time set.

4. Weld sequence begins.

5.

Trigger released; Crater sequence begins and

runs until crater timer expires.

6. Arc Extinguished; Burnback sequence begins and

runs until burnback timer expires.

7. Postflow sequence begins and runs until postflow

timer expires.

8. End of process.

WFS vs. Work point (Output) Waveform

= solid line represents WFS

---=

dashed line represents Work point or Machine Output

1 2 3 4 5 6 7 8