B-6 B-6

V205-T AC/DC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

OPERATION

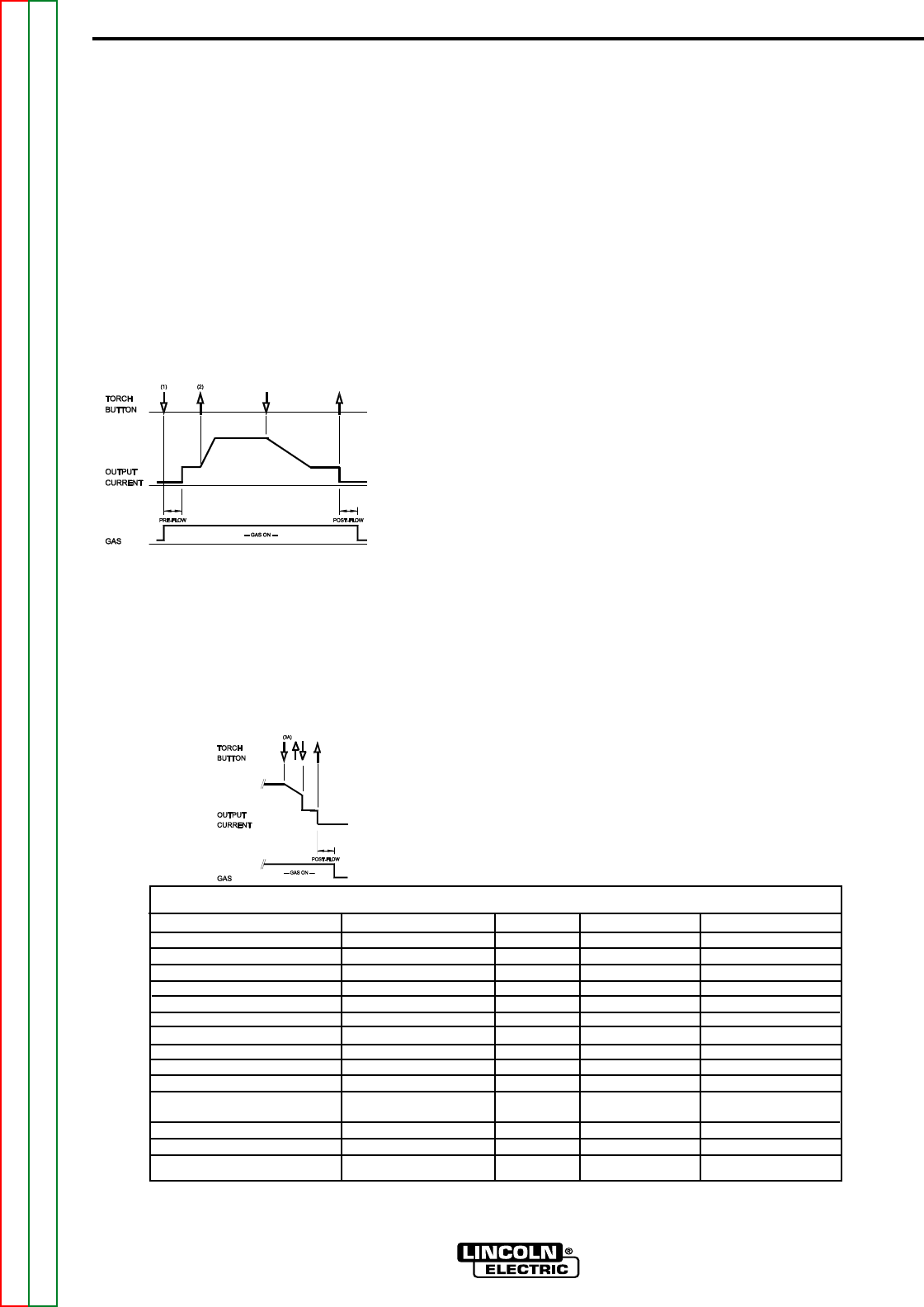

3. Press and hold the TIG torch trigger when the main

part of the weld is complete.

The machine will now decrease the output current at

a controlled rate, or downslope time, until the Finish

current is reached. Both the Downslope Time and

the Finish Current are presettable. This Finish cur-

rent can be maintained as long or as short as nec-

essary.

4. Release the TIG torch trigger.

The output current of the machine will turn OFF and

the gas valve will remain open to continue the flow

of the shielding gas. The duration of this postflow

time is adjusted by the Postflow parameter. This

operation is shown in (4 step diagram 1).

Possible variations of this standard sequence are

shown below.

By releasing and re-pressing the TIG torch trigger dur-

ing the downslope step, the output will immediately

drop to and hold at the Finish Current. Releasing the

trigger will turn off the output and begin postflow. This

operation shown in (4 step diagram 2)

9. Welding selection button - Permits selection of the

welding mode. The LED beside the symbol confirm

the selection:

• Stick

• TIG DC

• TIG AC

10. Electrode Connection (Negative) - For quick dis-

connect system using Twist-Mate

TM

cable plugs

with gas pass through for TIG Torches.

11. Remote Control Connector - For the connection

of a Lincoln Foot Amptrol, Hand Amptrol or Arc

Start Switch. See the ACCESSORIES section for

available options.

12. Electrode Connection (Positive) - For quick dis-

connect system using Twist-Mate

TM

cable plugs

13. Welding Parameter Display - LED’s show which

mode or welding parameter is activated for adjust-

ment.

• If it is necessary to modify the welding parameters

"Item 13":

- Wait four seconds after the LED’s on the

panel have gone out, the welding current

LED will be lit.

- Press the SETUP/Parameter push button

"Item 4"; every time the push button is

pressed, one of the LED’s in the diagram

“Item 13” comes on (in clockwise sequence)

and the value of the parameter appears on

the Digital display "Item 6". Stop at the

desired parameter.

- Rotate the Output/Parameter Adjust Knob"Item

5" and modify the parameter value.

- Press the SETUP/Parameter "Item 4" push

button again to pass to another parameter, or

wait five seconds and the Weld Current LED

will come on again.

4 STEP DIAGRAM 1

4 STEP DIAGRAM 2

WELDING PARAMETER DEFAULTS AND RANGES

PARAMETER VALUE MIN MAX DEFAULT

START CURRENT AMPS 6 MAX 15

UPSLOPE SEC. 0 10 0.2

WELD CURRENT* AMPS 6 MAX 100

DOWNSLOPE SEC. 0 10 1.0

FINISH CURRENT AMPS 6 MAX 8

POSTFLOW SEC. 0.2 60 5.0

PULSE FREQUENCY HZ 0.1 500 0.5

% ON TIME % 5 95 50

BACKGROUND CURRENT

% OF WELD CURRENT

1 100 20

AC FREQUENCY HZ 20 150 100

AC BALANCE % EN 35 85 65

(EN = Electrode Negative)

MODE DC TIG

TRIGGER 2 STEP

LOCAL / REMOTE LOCAL

(3)

(4)

* Maximum Weld Current can be limited by input voltage, Welding Mode, AC TIG waveform and AC TIG frequency.