24

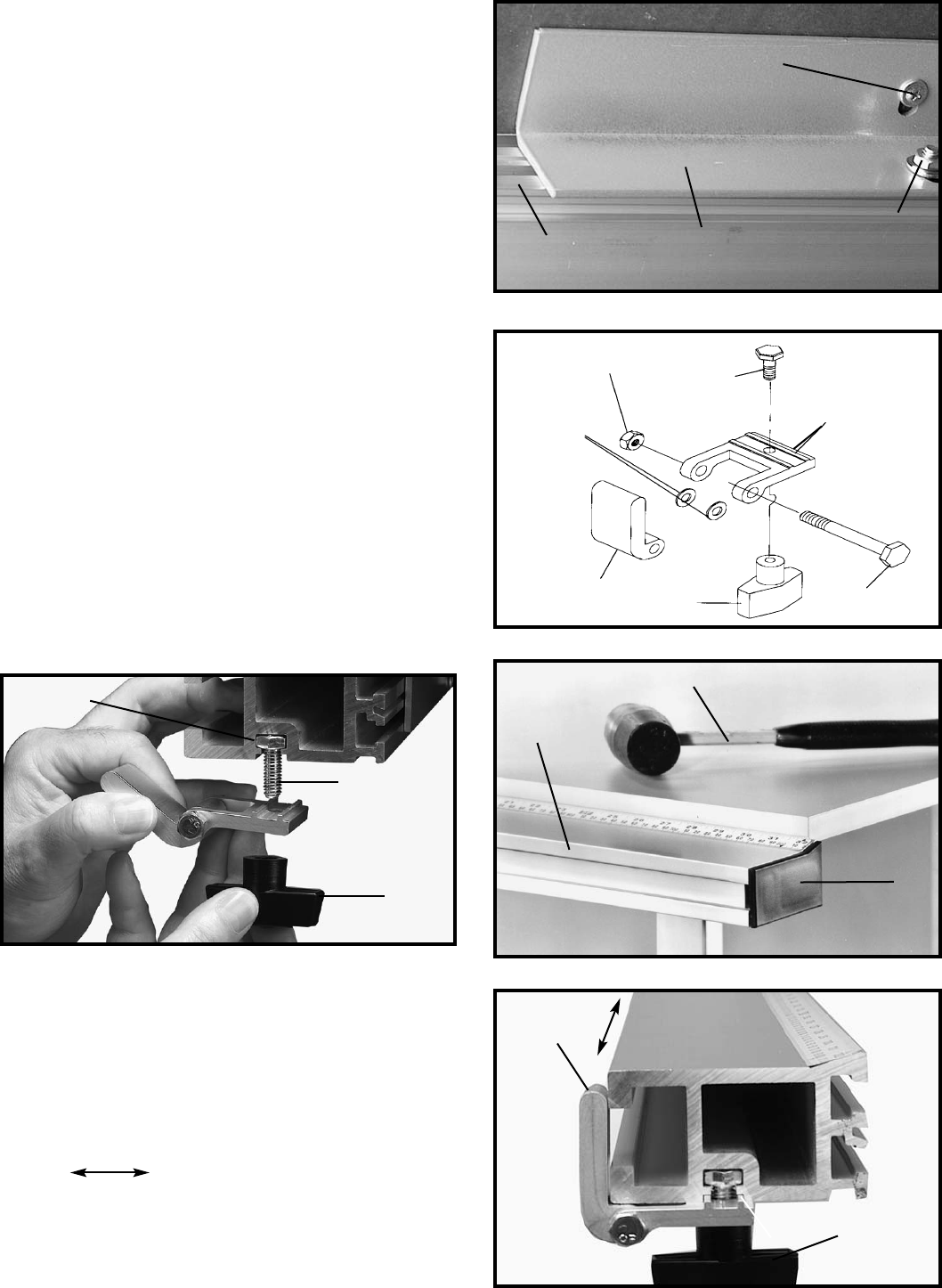

Fig. 64

Fig. 65

Fig. 67

Fig. 63

7. Move the square (H) Fig. 62, to the end of the

Unifence table and check to make certain the same

distance is kept from the top surface of the extension

table (K) to the top surface of the guide rail (C). Move the

front table support (L) Fig. 63, against the guide rail (C),

and fasten with 1/4-20 nut and flat washer (M). Tighten

two screws, one of which is shown at (N) Fig. 63, that

fasten the Unifence table to the guide rail.

SETTING T-SLOT

RAIL STOP

1. The Rail Stop Assembly Fig. 67 (A) can be set to any

number of positions along the guide rail providing a

quick stop setting for the Unifence body by loosening

knob (B) and sliding the stop along the rail to the desired

position ( ) and re-tighten.

NOTE: Any number of stops can be purchased and

installed to provide time saving quick stop adjustment

for the Unifence body.

Fig. 66

ASSEMBLING

RAIL STOP

1. The Unifence Flip Stop, Fig. 64, can be easily

assembled by inserting flip stop (A) into fence slide stop

(B) which is held in place by inserting 1/4-20 x 2″ hex

head bolt (C), fiber washers (D) and tightening hex nut

(E). Make sure fiber washers are placed on both sides of

flip stop (A) when assembled. Do not over tighten hex

nut (E). The flip stop must fit snuggly but move freely.

2. The Rail Stop Assembly, Fig. 65, can then be

attached to the guide rail by inserting head of 5/16-18 (F)

hex head bolt into T-Slot (G) positioning the stop

assembly to the rail and tightening knob (H) finger tight.

3. Use a rubber mallet (P) Fig. 66, or a hammer and a

block of wood, to gently tap end cap (R) into both ends

of the guide rail (C). NOTE: To avoid damage to the

guide rail, DO NOT use a metal hammer directly against

the guide rail.

R

P

C

M

N

L

C

A

B

C

D

E

F

G

H

A

B

F

H