ADJUSTING BLADE ALIGNMENT

WARNING: Blade Alignment is Factory Set and

should not need adjustment. Adjusting Blade Alignment,

in the field is a difficult and time-consuming procedure.

All Saw Blades have some run-out. Therefore, re-

adjusting blade alignment should only be attempted if it

becomes necessary. (See step 6 in CHECKING BLADE

ALIGNMENT.)

1. WARNING: Disconnect machine from power

source.

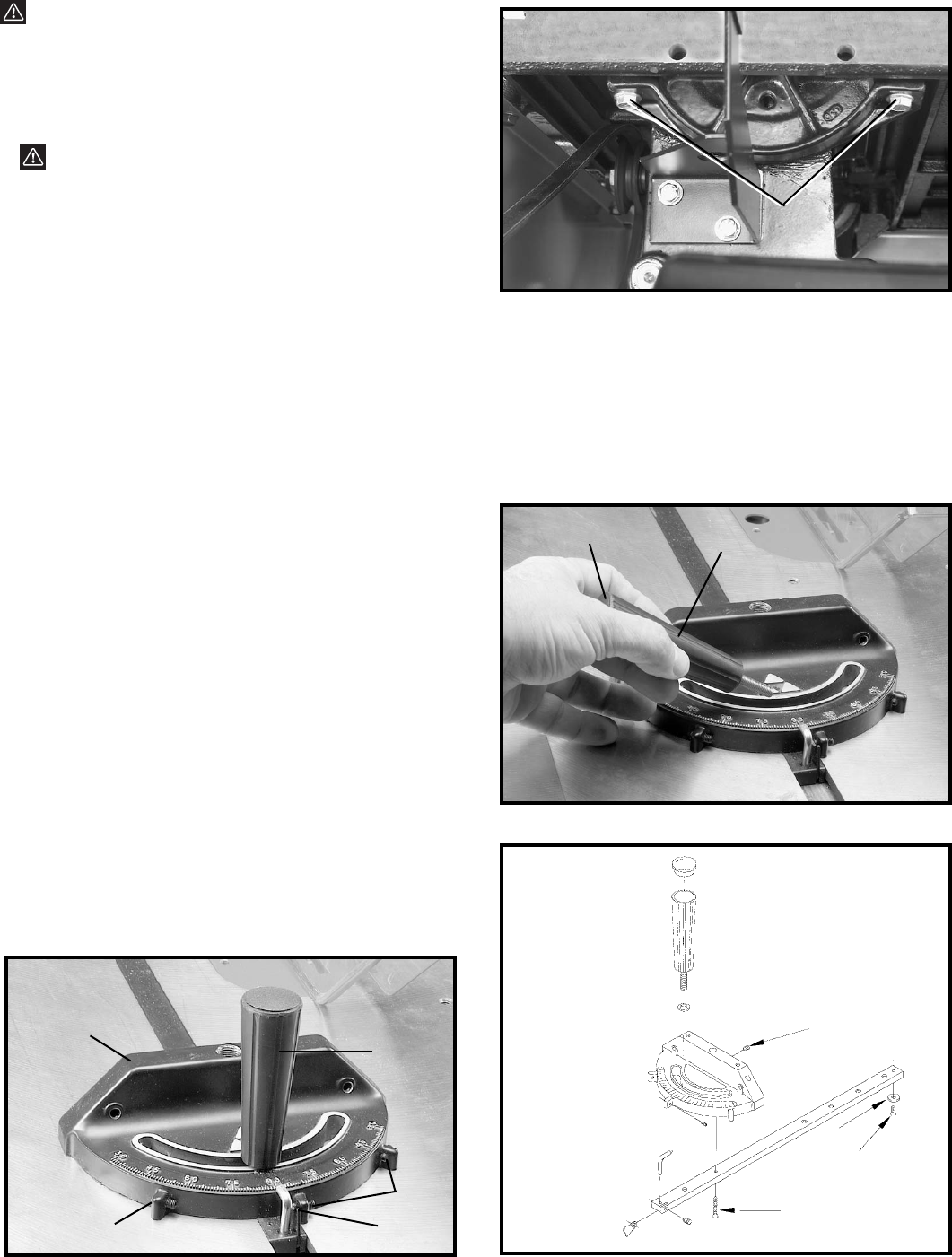

2. Lower blade. Remove blade guard and table insert. With

a 1/2″ wrench, loosen the 4 front and rear trunnion mounting

bolts (E) Fig. 101C. NOTE: Only the 2 rear trunnion mounting

bolts are shown.

3. Move the trunnion assembly in the desired direction.

Tap gently with rubber mallet if necessary.

4. To check blade alignment, follow (CHECKING BLADE

ALIGNMENT) procedure until proper alignment is achieved. Tighten 4 trunnion bolts (E).

5. Check blade alignment again after tightening bolts to confirm alignment. If alignment is off, loosen the 4

trunnion bolts (E) and repeat the above steps until proper alignment is achieved with bolts fully tightened.

6. Install table insert, blade guard, and lower blade before reconnecting power source.

MITER GAGE OPERATION AND ADJUSTMENT

1. Insert the miter gage bar into the miter gage slot and

assemble the washer and lock handle (A) Fig. 102, to the miter

gage bar. Insert cap (K) into top of handle (A).

2. The miter gage is equipped with adjustable index stops

at 90 degrees and 45 degrees right and left. Adjustment to

the index stops can be made by tightening or loosening the

three adjusting screws (B) Fig. 103.

3. To rotate the miter gage, loosen lock knob (A) Fig. 103,

and move the body of the miter gage (C) to the desired angle.

4. The miter gage body will stop at 90 degrees and 45

degrees both right and left. To rotate the miter gage body

past these points, the stop link (D) Fig. 103, must be moved

up and out of the way.

5. The head of the miter gage pivots on a special tapered

screw (G) that fastens the head to the miter gage bar. If the

miter gage head does not pivot freely, or pivots too freely,

adjust it by loosening set screw (H) Fig. 104, and turning the

screw (G), in or out. Be certain to tighten screw (H) after

adjustment is made.

33

Fig. 103

A

B

D

B

C

Fig. 101C

Fig. 102

Fig. 104

H

G

E

F

E

A

K