1 - 3

match for correct data transfer through the serial port using RS-232

protocol. Scan the RS-232 interface bar code below. This programs

the Development engine for an RS-232 interface at 115,200 baud,

parity-none, 8 data bits, 1 stop bit, and adds a suffix of a CR LF.

7. Verify the engine operation by scanning a bar code from the Sample

Symbols in the back of this manual. The engine beeps once when a

bar code is successfully decoded.

To connect a N4313/N4315 engine to your host system, please refer to the Inte-

gration Manual.

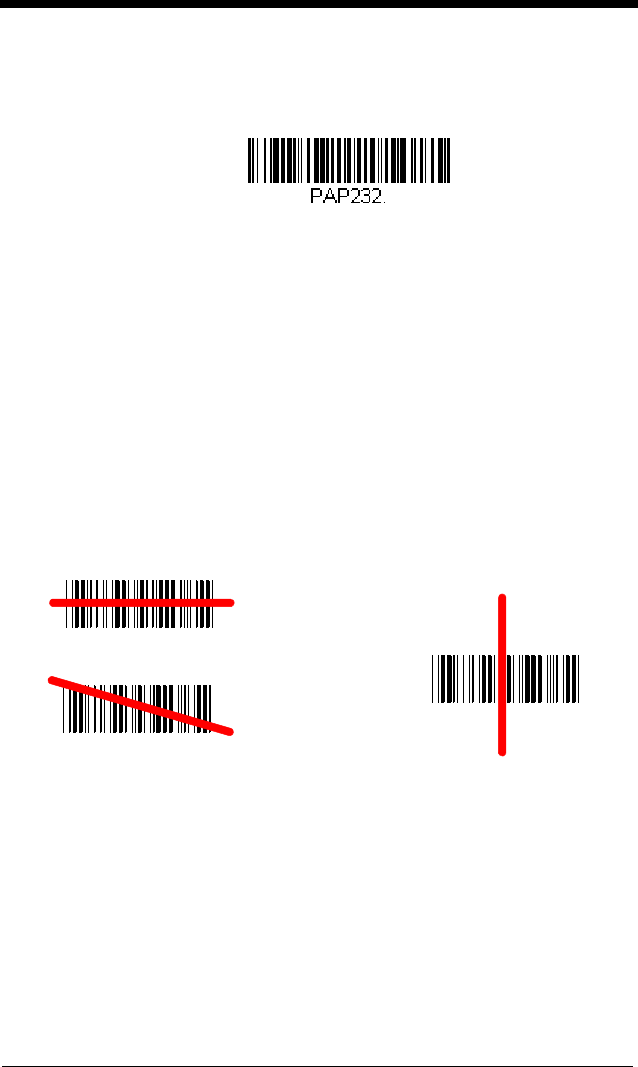

Reading Techniques

The engine projects a bright red scan beam that corresponds to the engine’s

scanning field of view. The scan beam should be centered horizontally over the

bar code and must highlight all the vertical bars of the bar code. It will not read

if the scan beam is in any other direction.

The scan beam is smaller when the engine is closer to the code and larger

when it is farther from the code. Symbologies with smaller bars or elements (mil

size) should be read closer to the unit. Symbologies with larger bars or ele-

ments (mil size) should be read farther from the unit. To read a symbol (on a

page or on an object), hold the engine at an appropriate distance from the tar-

get and center the scan beam on the symbol. If the code being scanned is

highly reflective (e.g., laminated), it may be necessary to tilt the code up 15° to

18° to prevent unwanted reflection.

Note: At 254mm a double beam of up to 3mm is to be expected. A double beam

will not affect scanning performance and is not a product defect.

RS-232 Interface

Good Read No Read