THEORY OF OPERATION

E-4 E-4

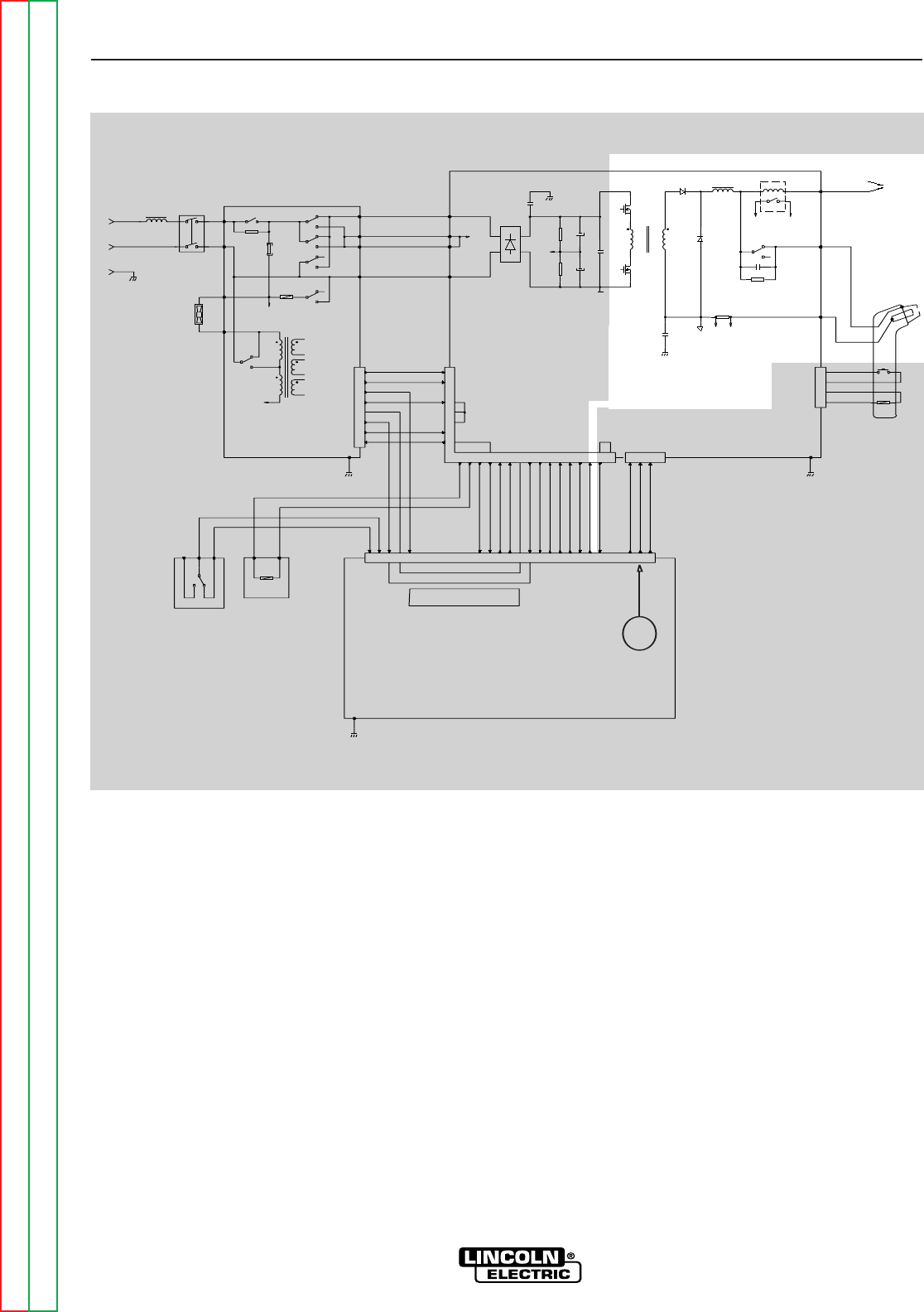

PRO-CUT 25

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

FIGURE E.4 – MAIN TRANSFORMER

115/230/1/50/60 VAC

INPUT

CN1

2

1

4

3

5

6

7

8

300uH

L1

RL3

10/10W

R1

V2

V1

B

A

1A/250V

F1

RL2

RL2

RL2

AC

CP

CP

AC

L1

RL1

RL2

115VAC

230V

T1

115V

RL1

L1

15VAC

15VAC

SAFETY

+28VDC

SEC GND

OVLOAD

115/230

+12VDC

AC

CP

CP

AC

CN2

6

9

10

2

20

1516

+15Vrms

EV1

NO

COM

NC

12VDC

PS2

PS1

861793

OVLOAD

SEC GND

SAFETY

CN1

121814 1 11 4 13 7 19 242123 8 1 2 3

3

22

17

V+

+12VDC

+12VDC_SW

+8V_SW

SEC GND

OVLOAD

TRANSFER SW

TRANSFER

SOL 1 DRIVER

SOL 2 DRIVER

TRIGGER

OUTPUT

V_OUT

121814 7 15 4 11 5 16101213

5

4

POT_WIPER

23

POT_CW

22

POT_CCW

24

CP

15K/3W

R1

15K/3W

R2

1500uF/250V

C2a,b

1500uF/250V

C1a,b

C12

CP

C26

IRG4BC30W

Q1a,b,c

IRG4BC30W

Q2a,b,c

SEC

PRI

T2

C13

D10

D11

240uH

Lout

SHUNT

SH-

SH+

BS1

8A

+12VDC

TRANSFER

C14

6.8k/5W

R24

WRK

NZL (2)

EL (3)

CN3

2

1

3

4

12VDC

PT

WORK CLAMP

CN1

SW1

230VAC

FN1

+

+

RL1

Display LED's

Control Board

Output Control

Air

Solenoid

1

Purge

Switch

Input

Voltage Board

Main Inverter Board

Solenoid 2

MAIN TRANSFORMER

The pair of IGBTs act as a switch assembly. This

assembly feeds a primary winding of the main trans-

former. When current is pulsed through this primary

winding, a resultant current is produced on the sec-

ondary winding of the main transformer. The DC cur-

rent flow through the primary winding is redirected or

“clamped” back to the filter capacitors when the IGBTs

are turned off. This is needed due to the inductance of

the transformer primary winding.

The primary current also passes through the current

transformer, which sends a signal to the control cir-

cuits of the inverter board. This signal and the control

circuits limit the maximum primary current flow

through the IGBTs. The pair of IGBT’s are fired at 15

microsecond intervals, creating a constant 66.6KHz

output.

The secondary portion of the main transformer is made

up of one winding. This winding supplies the

electrode-to-nozzle and electrode-to-work voltages

and the resulting currents. This high current winding is

capable of supplying maximum output current during

the cutting process. The output current is regulated

via pulse width modulation. The control circuitry, on

the inverter board, receives a signal from the control

board and regulates the output current to the desired

level.