TROUBLESHOOTING & REPAIR

F-27 F-27

PRO-CUT 25

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TORCH CONTINUITY AND SOLENOID TEST (continued)

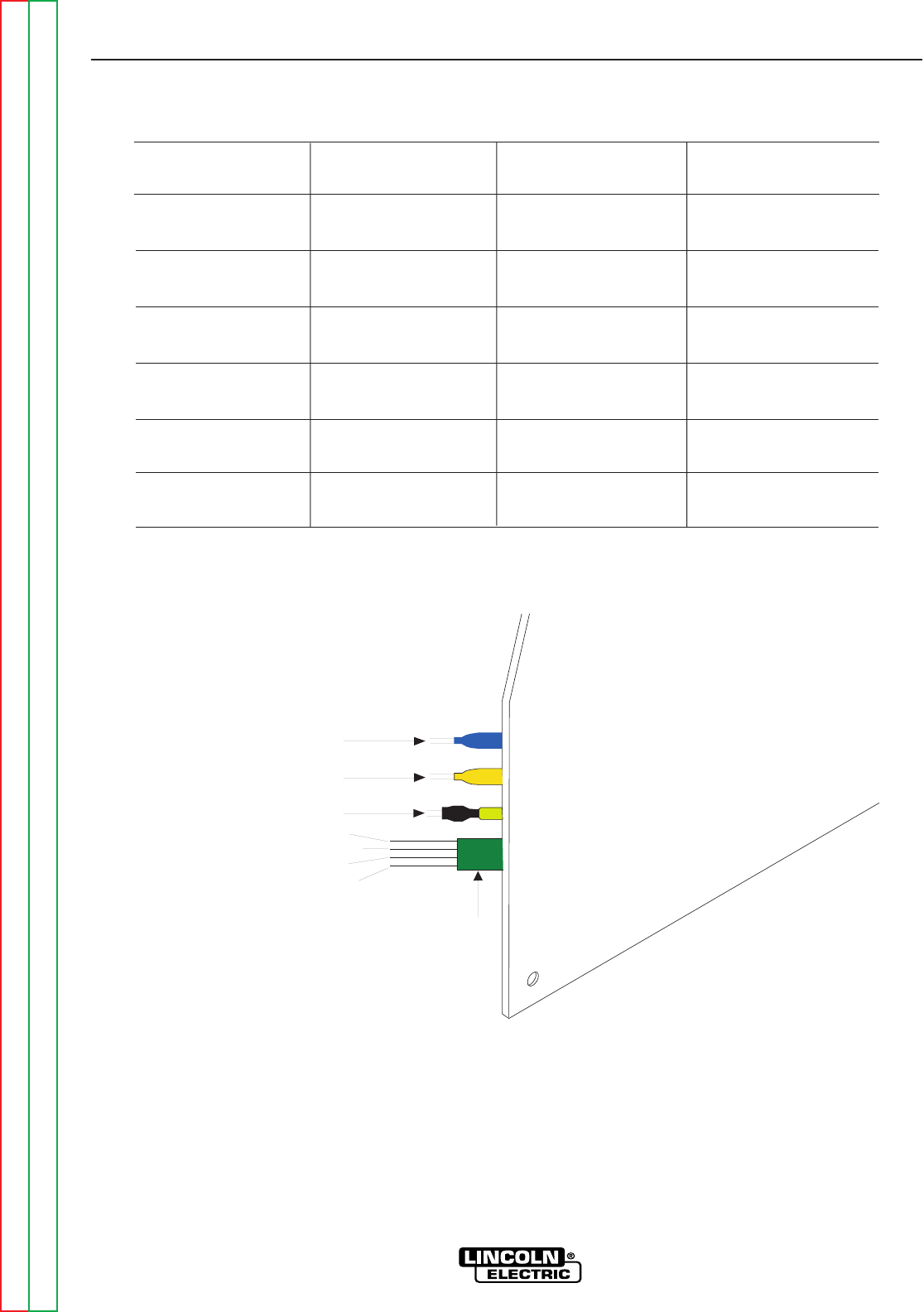

TABLE F.1 - TORCH ASSEMBLY RESISTANCES

TEST CIRCUIT(S) BEING EXPECTED TEST

POINTS TESTED RESISTANCE CONDITIONS

Lead #2 Pilot arc 1.5 ohms maximum Torch consumables

To Lead #3 leads in place

Lead #2 to Torch Pilot arc lead to 1.0 ohm maximum Torch consumables

Nozzle nozzle in place

Lead #3 to Torch Pilot arc lead to 1.0 ohm maximum Torch consumables

Nozzle nozzle in place

Pin 1 to Pin 2 Torch trigger circuit 100K ohms minimum Torch trigger NOT

Plug J1 (Red Leads) pulled (not activated)

Pin 1 to Pin 2 Torch trigger circuit 1.0 ohm maximum Torch trigger pulled

Plug J1 (Red Leads) (activated)

Pin 3 to Pin 4 Electrode Solenoid 45 to 55 ohms None

Plug J1 (Gray Leads)

10. Torch circuits may be measured when elec-

trode and nozzle are in place if the various cir-

cuits are isolated from each other. NZL (2),

Electrode (3), Trigger (1,2), and Torch leads (3,4)

should all measure greater than 1 Meg ohm when

checked as isolated circuits. See Figure F.10

Diagram.

11. Replace leads and plugs previously

removed.

(LEAD 2) NZL

WRK

(LEAD 3) EL

Harness

Plug J1

1

2

3

4

Figure F.11