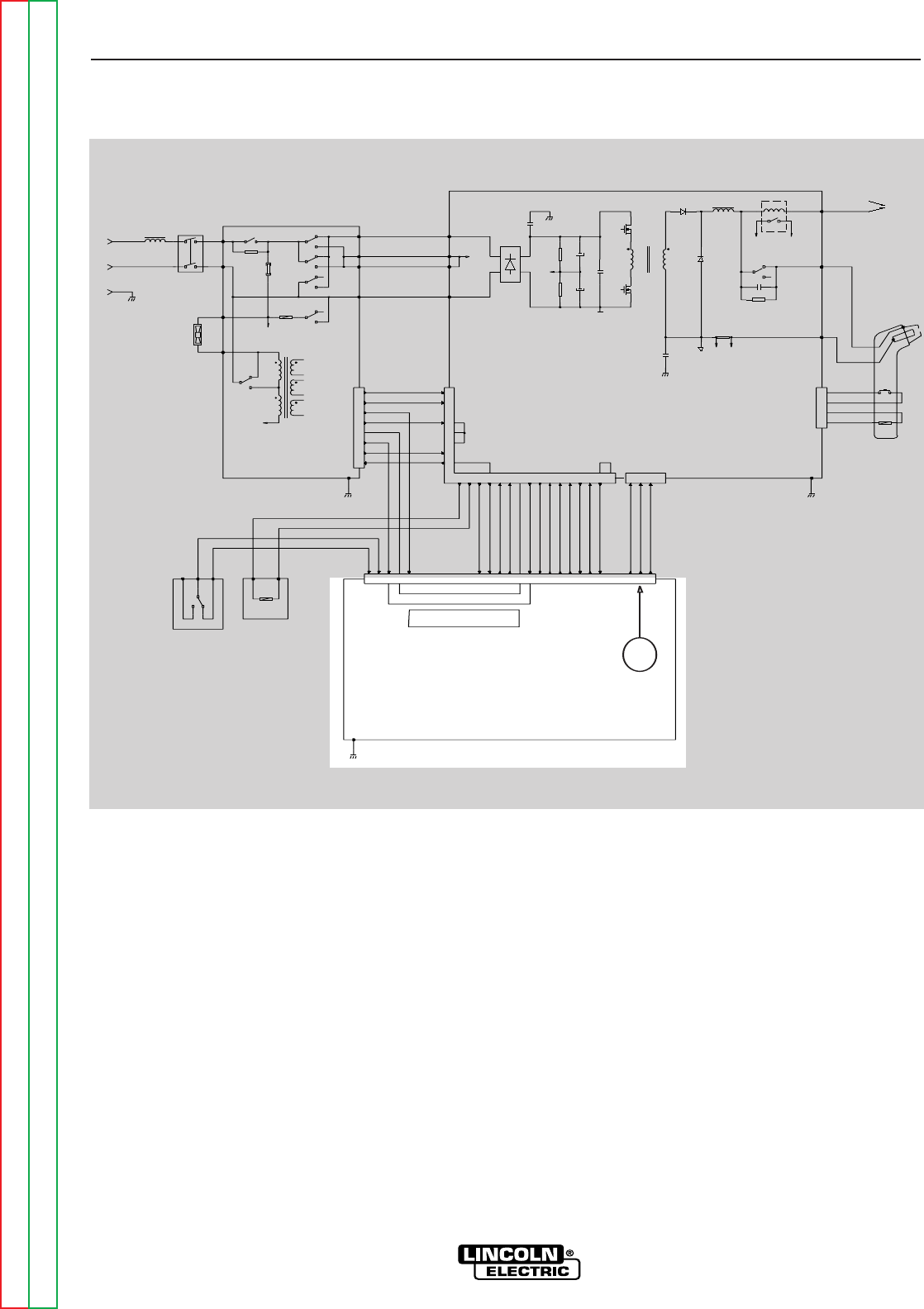

CONTROL BOARD

The control board receives status and analog

feedback signals from the inverter board, input board,

and various sensors. The control circuitry interprets

these signals, makes decisions and changes the

machines mode and output to satisfy the requirements

as defined by the circuitry. The control board sends a

signal to the inverter board to control the output

current but the actual regulation circuits are on the

inverter board.

The display board, directly connected to the control

board, communicates PRO-CUT 25 status and

operating conditions to the user. There are four status

indicators: Power On, Gas Pressure, Thermal

Overload, and Safety Error.

THEORY OF OPERATION

E-6 E-6

PRO-CUT 25

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

FIGURE E.6 – CONTROL BOARD

115/230/1/50/60 VAC

INPUT

CN1

2

1

4

3

5

6

7

8

300uH

L1

RL3

10/10W

R1

V2

V1

B

A

1A/250V

F1

RL2

RL2

RL2

AC

CP

CP

AC

L1

RL1

RL2

115VAC

230V

T1

115V

RL1

L1

15VAC

15VAC

SAFETY

+28VDC

SEC GND

OVLOAD

115/230

+12VDC

AC

CP

CP

AC

CN2

6

9

10

2

20

1516

+15Vrms

EV1

NO

COM

NC

12VDC

PS2

PS1

861793

OVLOAD

SEC GND

SAFETY

CN1

121814 1 11 4 13 7 19 2421 23 8 1 2 3

3

22

17

V+

+12VDC

+12VDC_SW

+8V_SW

SEC GND

OVLOAD

TRANSFER SW

TRANSFER

SOL 1 DRIVER

SOL 2 DRIVER

TRIGGER

OUTPUT

V_OUT

121814 7 15 4 11 5 16101213

5

4

POT_WIPER

23

POT_CW

22

POT_CCW

24

CP

15K/3W

R1

15K/3W

R2

1500uF/250V

C2a,b

1500uF/250V

C1a,b

C12

CP

C26

IRG4BC30W

Q1a,b,c

IRG4BC30W

Q2a,b,c

SEC

PRI

T2

C13

D10

D11

240uH

Lout

SHUNT

SH-

SH+

BS1

8A

+12VDC

TRANSFER

C14

6.8k/5W

R24

WRK

NZL (2)

EL (3)

CN3

2

1

3

4

12VDC

PT

WORK CLAMP

CN1

SW1

230VAC

FN1

+

+

RL1

Display LED's

Control Board

Output Control

Air

Solenoid

1

Purge

Switch

Input

Voltage Board

Main Inverter Board

Solenoid 2