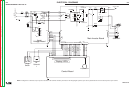

ELECTRICAL DIAGRAMS

G-3

PRO-CUT 25

WIRING DIAGRAM W/ADDITIONAL INFO

pressure

Schematic 98056 (SIPC 25)

Schematic 99016 ( SPA25)

Schematic 98044

Purge Switch (n.o.)

Gas Psi

.

Thermo

Safety led

Input Power

8

vdc

when

open

for

correct

pressure

RL1

RL3

Auto

reconnect

card

RL1

(control bd

mounted)

50hz /60

hz

RPM’s 2700/ 3100

amps .13 / .12

runs all the time

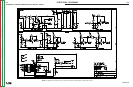

Pcb

.

card

relay

Reconnect

pilot relay

+12 v

8vdc @ min

10-5

vdc

@ max.

(power supplies from

inverter bd.

for pot only!!)

This bd

generates 8 vdc

which get its input from

the inverter bd

. via the

12

vdc

on the inverter bd

.

8v is used on both

bds.

8vdc

(pip)

reset by turning off PC25

also

input overload

all LED’s come on

initally

then just the POWER led is lit

THERMO led stays lit for

approx

3 sec also at turn on.

12v=230

0v =115

+15Vrms

( reed )

( relay )

Soft start relay

3 to 5 sec delay

(12

vdc

)

Soft start resistor

( over heats on 208 input !)

Shown in 230

de-energized

+12 VDC

sw

supply is used for:

1. Output control (control).

& its ref bd. (invert)

2. Shunt feedback ( invert)

3. Transfer relay (invert & control)

4. Torch solenoid (

inv

& control)

5. LED supply

+8 VDC supply is used for:

1. Turn on PWM (invert)

2. PIP detect

ckt.(control)

3. Pilot arc timer (control)

4. Purge

ckt

button(control)

5. Drivers for LED logic (control)

6. Torch solenoid logic

ckt(control)

7. Air solenoid logic

ckts

& driver (control)

8. Transfer relay (invert) Logic &driver(control)

Represents:

board soldered to

a mother

bd

.

Represents:

relay soldered to

a mother

bd

.

DC

REF bd

card

PWM

driver

card

PWM

card

reg

+12V

( pwm gate drive signal)

+12

vdc

+15Vrms

PT3

amp

shunt input

+12V

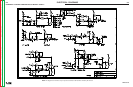

inverter bd

.

inverter bd

.

common for

trigger

pink

pink

230vac

Auto reconnect

ckt

.

PIP supply 20

vac

{

Supply for torch,&

main air solenoid .

12 V regulator

on inverter bd

.

Vs =OK

0v= over

load.

{

over

volts

signal

{

{

This is the voltage

reconnect for 110V

operation

(voltage

doubler

)

operating

freq

. 63

khz

/ 100khz

(PC 25) / (PC20)

All

thermo devices are on this

inverter board

primary current

feedback c.t.

primary c.t.

( air )

( torch)

Q4

Reco

nnect

mai

nrelay

+12V

Aux

fuse

OVL signal

+8 = on (from

control bd.)

isolated

+20

Vdc

for NO parts in place(pip)

+6

Vdc

with parts IN

4.7nf

4kv

4.7 f

4kv

To

pwm

chip

sec

thermo

PT2

(N.C.)

F.e.t.

thermo

PT1

(N.C.)

some

‘s

some

‘s

300

VDC

Mai

n

Cap

s.

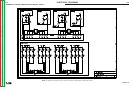

to

nozzle

ckt

.

*does it work

in the other input

voltage 115v or 230 v ?

If it does, it is an

input

bd

.

Listen for relay to

click

in

after a 3 sec delay

On f

or 110v

ac

+8v = no output

6v = output

To

{

+12v =pilot

0 = cutting

To

{

+8v = open trigger to

Choke

Thermo

( PCT)

P

T3

(N.O.)

+ 12 from Control bd

.

Reed switch (BS1)

closes when cutting

current is drawn

To Control bd

.

400Vocv

100v pilot &cutting

25a @ 35% duty (115 input)

25a @ 60% duty (230 input)

12 to 25 amps range

3/8 max thickness @ 30 amp input

+8V

direct to control bd..

+12v = sol off

0v = sol on

Must be

a

PC 25 nozzle!

S22147-028

no drag cups either

!

try without.

Must be to within

1/8 ” to transfer to cut.

cutting

+12V_

sw

Transfer relay

(signal from

control

bd

.)

shown in pilot

2.2 f/400v

Must double hit

when first turned on

input ( safety feature)

or after

thermo

reset

not so in

preflow

.

Torch solenoid:

supply from inverter

bd

.

Control is from control

bd

.

45 to 55 ohms

Cuts for 3 sec then quits

(stuck in pilot mode )

or

pilot current is 1/2 of

cutting current

EV2

Trigger:

8v when open

reg

+8

vdc

+12V_sw

8V

i

nput

+8

comes “on” at turn on

for 3 sec.

“see” pip

ckt

inset detail

“see” pip

ckt

inset detail

Scaled

down

version

of

output

+12

V= ok

0v = overload

(choke thermo or input bd

.)

2 f

400v

RHRG30120

PILOT PATH

PIP PATH

CUTTING PATH

PIP

PILOT

CUTTING

choke

5

00

V

Must be within

+/- 10% of input.

Must be greater than 208v.

YES for Ranger 250 series

Commander 300, 400 ,500’s

Auto Reconnect Feature

Air

Guage

Supply pressure must be:

80 to 150

psi

with a flow

rate of no less than 4.0

cfm

(113 l/min.)

240

cfh

Set air pressure while in

purge

to

65

psi

.

comes on if

no gas

psi

.

( over volt detect )

CN1-3

CN1-7

Input bd

Inverter bd

Control bd

.

20

vac

***

Detail***

PIP (safety

ckt

.)

CN1-4

CN1-3

CN2-11

CN2-6

NZL

EL

+20 Vdc for NO parts

in place(pip)

+6

Vdc

with parts IN

LED

ckt.

10 K

torches of

15 or 25ft are ok

all

ckt

. commons

0 170

65

50 150

Ckt

.

Ckt

.

Display

bd & Driver bd

.

indicates that

the +12 on inverter

bd

is up ( not the +8)

“see” pip

ckt

inset detail

PILOT

Current

is 12 amps

Typical input current draw:

115v 25A/35% = 37.7A

20A/60% = 26.7A

230v 25A/60% = 19A

20A/100%=15A

13

2 . 5

K

PRO CUT 25

file: procut25.pp

3-11-02 3-6-03

3-20-02

Closes @ 43.5

psi

(3bars)

Opens@ 37.7 to 42

psi

(2.6 to 2.9 bars)

when in 230

115vac

115vac

when in 115

when in 115

R

e

m

o

ve

e

le

c

t

r

od

e

.

C

h

e

c

k

f

o

r

s

h

o

r

t

s

&

o

p

e

n

s

t

o

ot

h

e

r

l

ea

d

s

G-3

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC