Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-30 F-30

PRO-CUT 25

AIR/GAS SOLENOID TEST (continued)

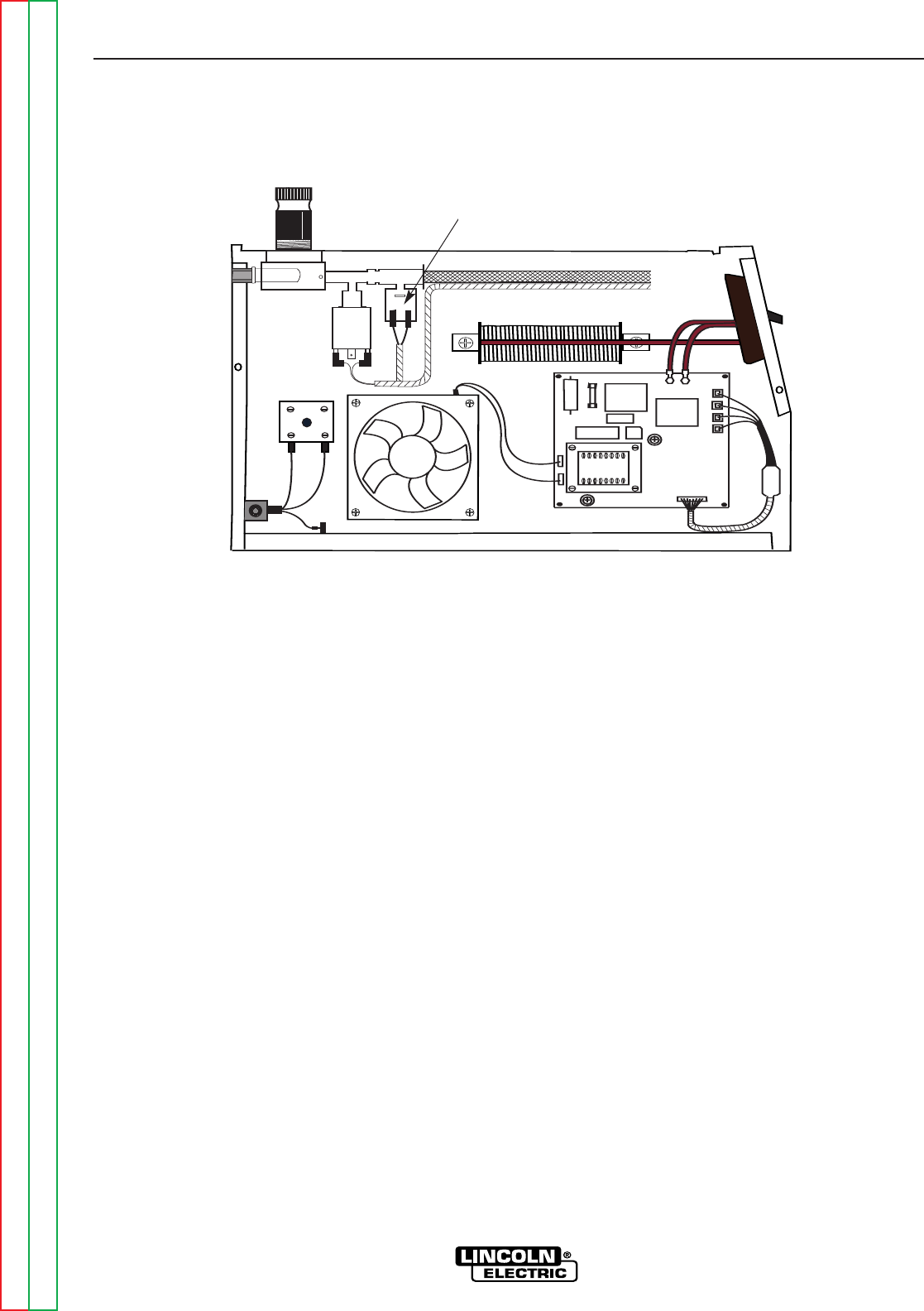

TEST PROCEDURE

1. Remove input power to the PRO-CUT 25

machine.

2. Remove carrying handle using a 4mm allen

wrench.

3. Using a crescent wrench, carefully remove

the plastic nut from around the pressure

regulator located on the top of the machine.

4. Using a 7mm nut driver, remove the case

wraparound.

5. Perform the Input Capacitor Discharge

Procedure detailed earlier in this section.

6. Locate the air solenoid and leads. Carefully

remove the two leads from the Solenoid. See

Figure F.12.

7. Check the coil resistance of the solenoid at

the two terminals. Normal resistance is

approximately 13 ohms. If the resistance is

abnormal, the Solenoid may be defective.

8. Carefully apply the 12 VDC supply to the

solenoids lower two terminals. With proper

air pressure applied, the solenoid should

activate and air should flow from the torch

nozzle. If the solenoid activates but air does

not flow, check for a restriction in the air line

or torch.

9. Reinstall the two leads previously removed.

FIGURE F.12 – AIR SOLENOID

LEFT SIDE OF MACHINE

A

B

Air Solenoid