Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

PRO-CUT 25

TROUBLESHOOTING & REPAIR

F-6 F-6

Observe Safety Guidelines

TROUBLESHOOTING GUIDE

detailed in the beginning of this manual.

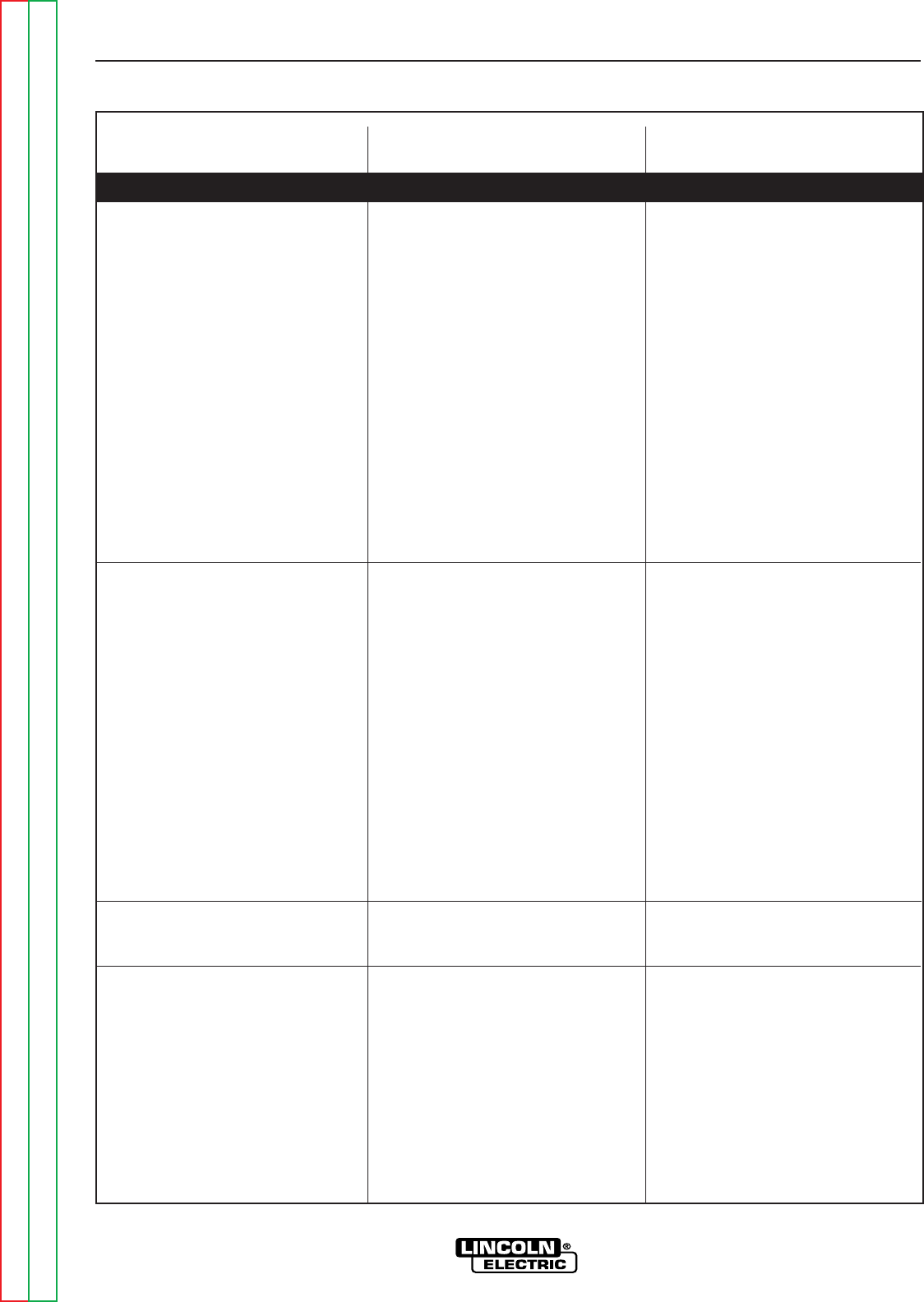

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

FUNCTION PROBLEMS

The cutting arc starts but sputters

badly.

1. Make sure the operating proce-

dure is correct for the process.

See the Operation section of

the manual.

2. Make sure the work clamp is

connected tightly to the work

piece.

3. Make sure the torch consum-

able parts are in place and in

good condition. Replace if

necessary.

4. Make sure the air pressure is

set at 65psi.

5. Make sure the air supply is not

contaminated with oil or

excessive water.

1. Check all connectors and

wires for loose or faulty con-

nections. See Wiring Diagram.

2. Perform the Torch Continuity

and Solenoid Test.

3. Perform the Main Inverter

Board Voltage and Resistance

Tests.

4. The control board may be

faulty. Replace.

5. Use the correct extension cord.

See the instruction manual.

The pilot arc is normal, but the arc

will not transfer to the work piece.

1. Make sure the operating

procedure is correct for the

process. See the Operation

section of the manual.

2. Make sure the work clamp is

connected tightly to the work

piece.

3. The work piece must be electri-

cally conductive material, and

the work clamp must make a

good electrical connection with

the work piece.

4. Do not use a drag cup. Not

recommended for Pro-Cut 25

use.

1. Check all connectors and

wires for loose or faulty con-

nections. See Wiring Diagram.

2.

Perform the Main Inverter

Board Voltage and Resistance

Tests.

3. The control board may be

faulty. Replace.

Trigger or purge is activated brief

air flow then the safety light illumi-

nates.

1. The Control Board is defective.

Replace.

Poor performance of pilot arc or

cutting. Poor consumable life.

1. Check pressure switch to be

functioning correctly

(opening/closing) at its correct

pressure.

2. Check pressure gauge to be

correct in its reading.

3. Check for recommended flow

rate coming from the torch end

with a flow meter.

1. Try increasing or decreasing the

air pressure to see if conditions

improve.

2. Replace regulator or pressure

switch may be required.

3. Screen in air line at inlet to air

solenoid may be clogged.

Clean. (no screen before 7/1/02)

4. Ensure that air is clean and dry

External filters may be used.